Maintenance Procedures

50 ARTC-SVX002A-EN

Federal Clean Air Act

Responsible refrigerant practices are important to the

environment, our customers, and the air conditioning

industry. All technicians who handle refrigerants must be

properly certified. The Federal Clean Air Act prescribes

procedures for handling, reclaiming, recovering, and

recycling of refrigerants and the equipment that must be

used in maintenance procedures involving potential

leakage of HVAC refrigerants. State and local

governments may have additional requirements that must

be followed to responsibly handle HVAC refrigerants.

Inspection and Maintenance

Schedule

Proactive measures should be taken to prevent potential

problems with the chillers. These include maintaining a

operational log and conducting weekly, quarterly, and

annual inspections of the chiller.

Daily

A daily visual inspection can reveal obvious problems.

Keep notes of the chiller performance:

• Log pressures and temperatures.

• Visually inspect of the unit. Check for noises, as well

as, oil or refrigerant leaks.

NOTICE

Component Damage!

Failure to follow instructions could damage sensitive

electronic components beyond repair. To prevent arcing

or surges of electrical current, do not use wires or

cables to jump components or bypass the

manufacturer's safety systems.

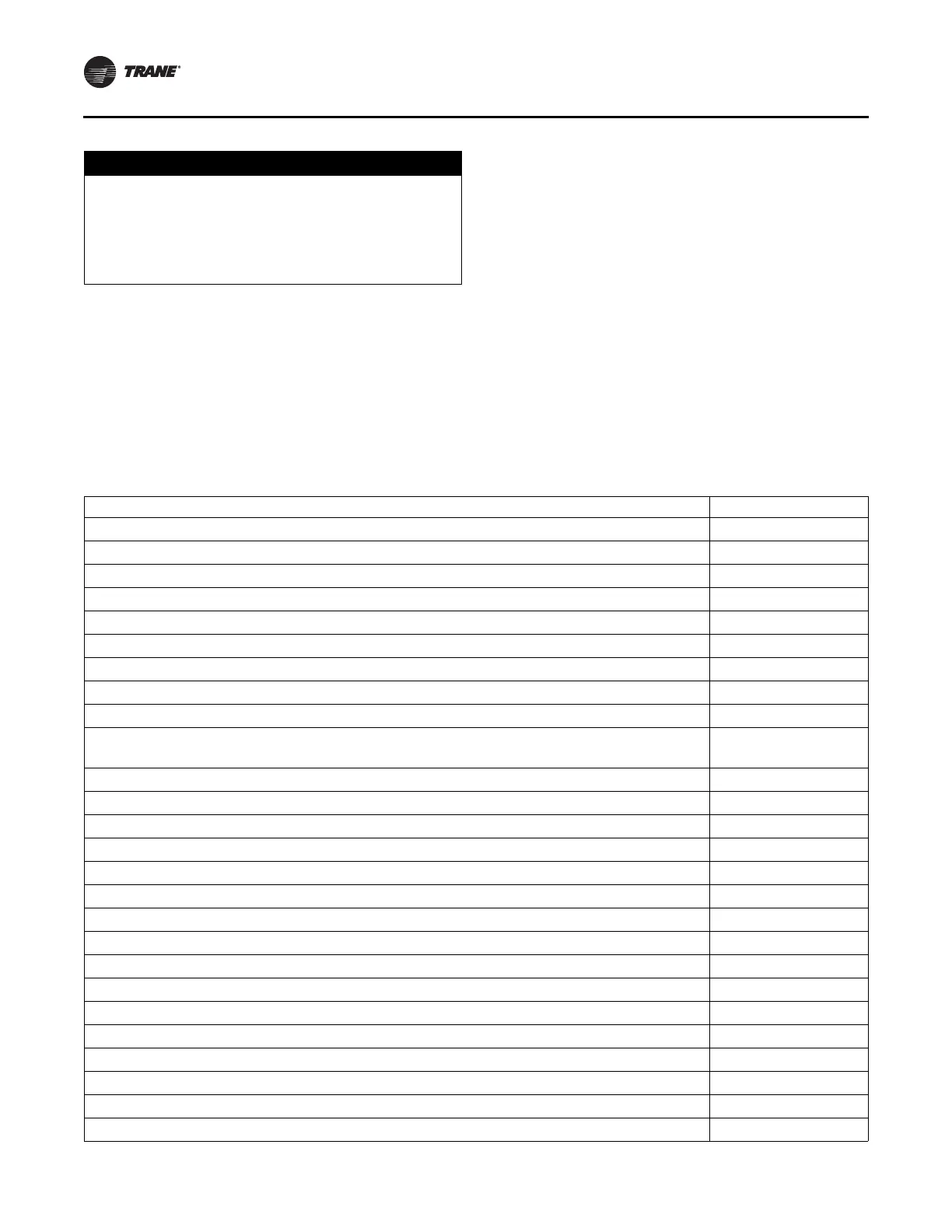

Table 10. Recommended chiller service intervals

Task Frequency

Visually inspect the chiller Daily

Log pressure and temperatures Daily

Inspect touchscreen interface panel for alarm history Weekly

Clean strainers on the inlet water pipe Monthly

Check the compressor oil level sight glass Monthly

Confirm the glycol concentration Monthly

Confirm the refrigeration pressures Monthly

Check the refrigeration liquid line sight glass Monthly

Inspect refrigerant pressures and temperature set points Quarterly

Inspect superheat (10 °F to 12 °F [5°C to 6°C]) and sub-cooling temperatures

(10°F to 15°F [5°C to 8°C])

Quarterly

Inspect the evaporator entering and leaving evaporator temperature Quarterly

Collect water/glycol mixture sample for analysis Quarterly

Inspect crankcase heaters Quarterly

Inspect piping for signs of leaks Quarterly

Inspect refrigerant piping for oil or refrigerant leaks Quarterly

Observe refrigeration operating pressures Quarterly

Confirm motor amperage draw and voltage Quarterly

Confirm chiller superheat and sub-cooling Quarterly

Check for worn or burned contactors Quarterly

Inspect all electrical connections and fuses Annually

Inspect each compressor for refrigerant pressures, overheating, oil leaks Annually

Inspect compressor terminals for pitting, corrosion, and loose connections Annually

Inspect compressor oil level Annually

Confirm and record compressor amperage draw and voltage Annually

Compare water/glycol flow against design specifications Annually

Tighten compressor rotalock nuts Annually

Loading...

Loading...