36 CNT-SVX08F-EN

PID Control

20. Record the measured value when it stabilizes. The temperature stabilizes at 70°F (21°C).

21. Manually control the analog output to 50% or 100%. Control the output to 100% (completely

opening the heating valve).

22. Record the measured value when it stabilizes. The temperature stabilizes at 120°F (49°C)

23. Subtract the measured value determined in step 2 fro

m the measured value determined in step

4. This is the change in the measured value.

120 - 70 = 50°F (49 - 21 = 28°C).

24. Calculate two-thirds (66%) of the change in measured value determined in step 4. Add this value

to

the in

itial temperature to determine at what point two-thirds of the total change occurs.

In the example, 0.66 × 50°F = 33°F, so two thirds of the tota

l change

occurs at 70°F + 33°F = 103°F

(0.66 × 28°C = 18°C; 21 + 18 = 39°C).

25. Again, set the analog output to 0% and allow the measured value to stabilize. The measured

value stabilize

s at 70°F (21°C).

26. Control the output to the value used in step 3 and record the time

it takes to reach the two-thirds

point determined in step 6. This is the system time constant. The time it takes to reach 103°F

(39°C) is 2.5 minutes (150 seconds).

27. Divide the system time constant by 10 to determine

the starting samp

ling frequency.

150 seconds ÷ 10 = 15 seconds.

Note: Th

e system time constant is the time it takes

to reach 63.21% of the difference between the

start point and the end point. Determining two-thirds (66%) is accurate enough for our

purposes.

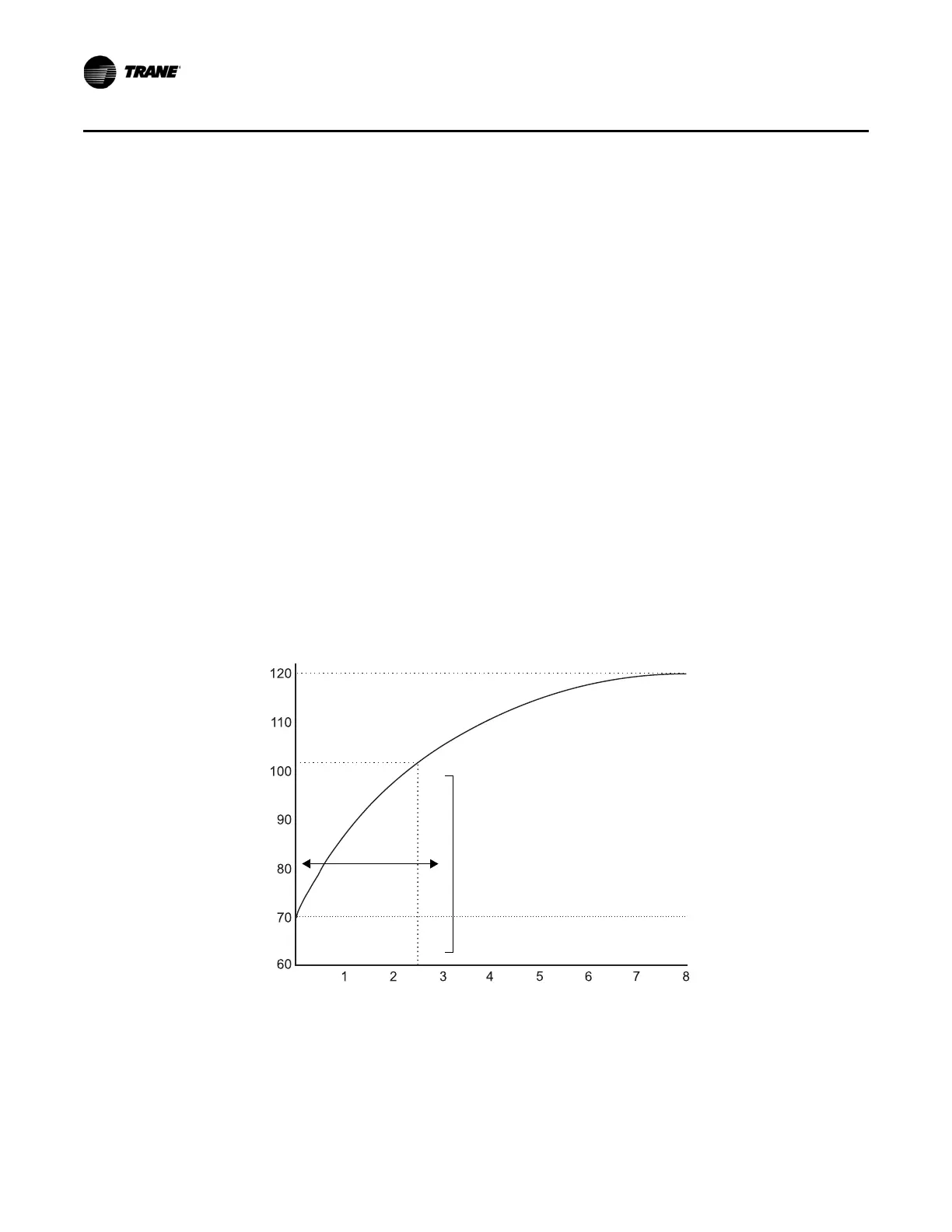

Figure 18 illustrates the procedure described above.

Figure 18. Determining the system time constant

System time

constant

Time (minutes)

Space temperature (°F)

Initial value (valve closed)

Final value (valve open)

2/3 of total change

Example

This scenario describes finding the sampling frequency for a PID loop controlling a heating

application.

28. Fully close the output.

29. The stabilized temperature reads 60°F (16°C).

Loading...

Loading...