RT-SVX23D-EN 47

Start-Up

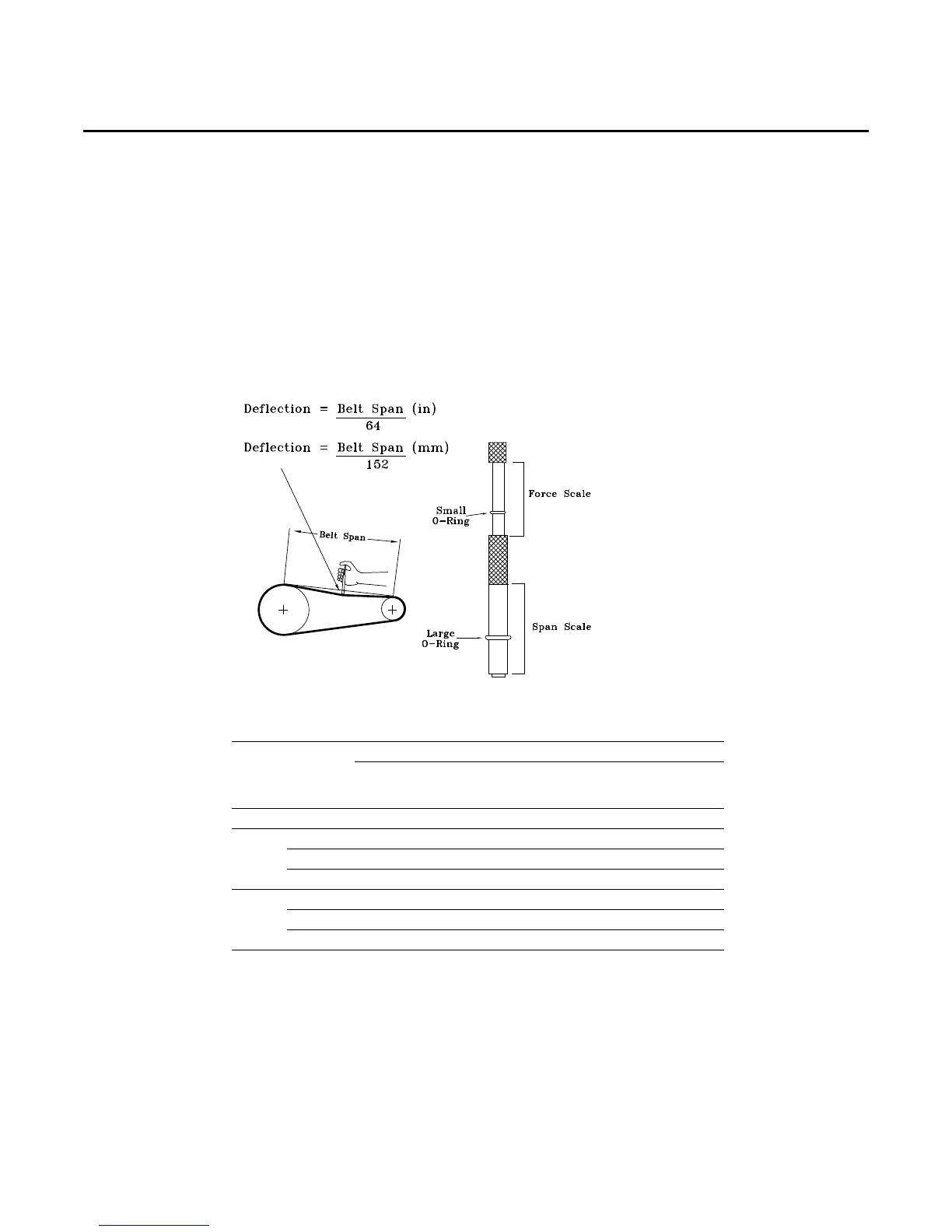

5. Remove the belt tension gauge. The small O-ring now indicates a number other than zero on

the plunger’s force scale. This number represents the force (in pounds) required to give the

needed deflection.

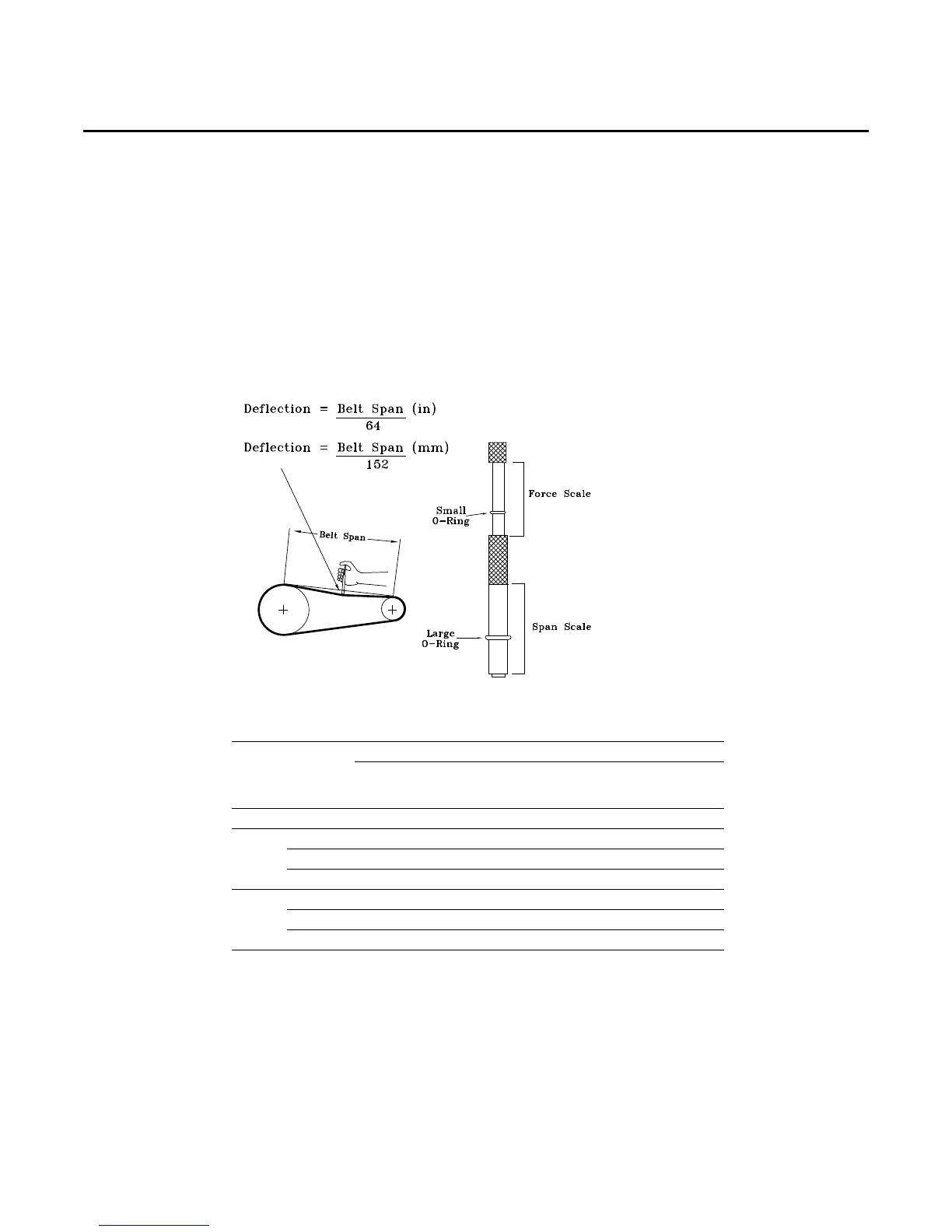

6. Compare the “force” scale reading (Step 5) with the appropriate “force” value listed in Tab le 8 .

If the “force” reading is outside the range, readjust the belt tension.

Note: Actual belt deflection “force” must not exceed the maximum “force” value shown in

7. Recheck the belt tension at least twice during the first 2 to 3 days of operation. Belt tension may

decrease until the new belts are “run in”.

Figure 29. Belt tension gauge

Table 8. Belt tension measurement and deflection ranges

Deflection Force (Lbs.)

Belts

Cross

Section

Small P.D

Range

Super Gripbelts Gripnotch

Steel Cable

Gripbelts

Min. Max. Min. Max. Min. Max

A

3.0 - 3.6 3 4 1/2 3 7/8 5 1/2 3 1/4 4

3.8 - 4.8 3 1/2 5 4 1/2 6 1/4 3 3/4 4 3/4

5.0 - 7.0 4 5 1/2 5 6 7/8 4 1/4 5 1/4

B

3.4 - 4.2 4 5 1/2 5 3/4 8 4 1/2 5 1/2

4.4 - 5.6 5 1/8 7 1/8 6 1/2 9 1/8 5 3/4 7 1/4

5.8 - 8.8 6 3/8 8 3/4 7 3/8 10 1/8 7 8 3/4

Loading...

Loading...