Trimax Snake mowers are designed to operate well in many kinds of grass or terrain conditions,

but the operator has the responsibility of being familiar with and following all operating and safety

procedures.

The lift rams are of the single acting type so hydraulic pressure can only be applied to one side of the ram

piston to lift the mower decks. Operating the hydraulic controls to lower the decks simply opens the valve

and allows the weight of the mower decks to force the hydraulic fluid back to the reservoir. There are two

primary advantages of this system. Simplicity is one – there is only one hose to connect. The other is that

the rams cannot apply downward force to the outriggers, which could damage the transport locks.

15a. Transport Locks.

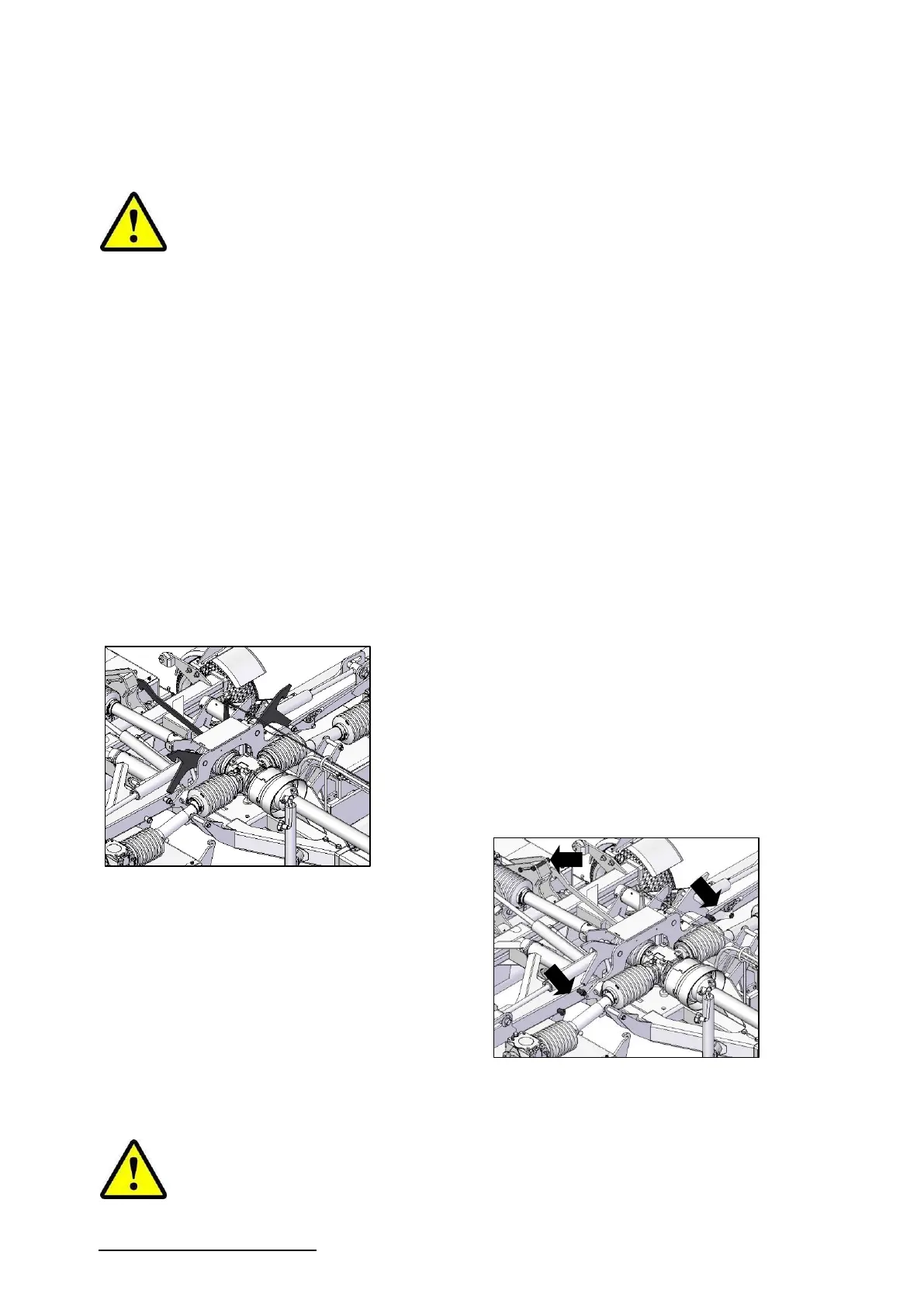

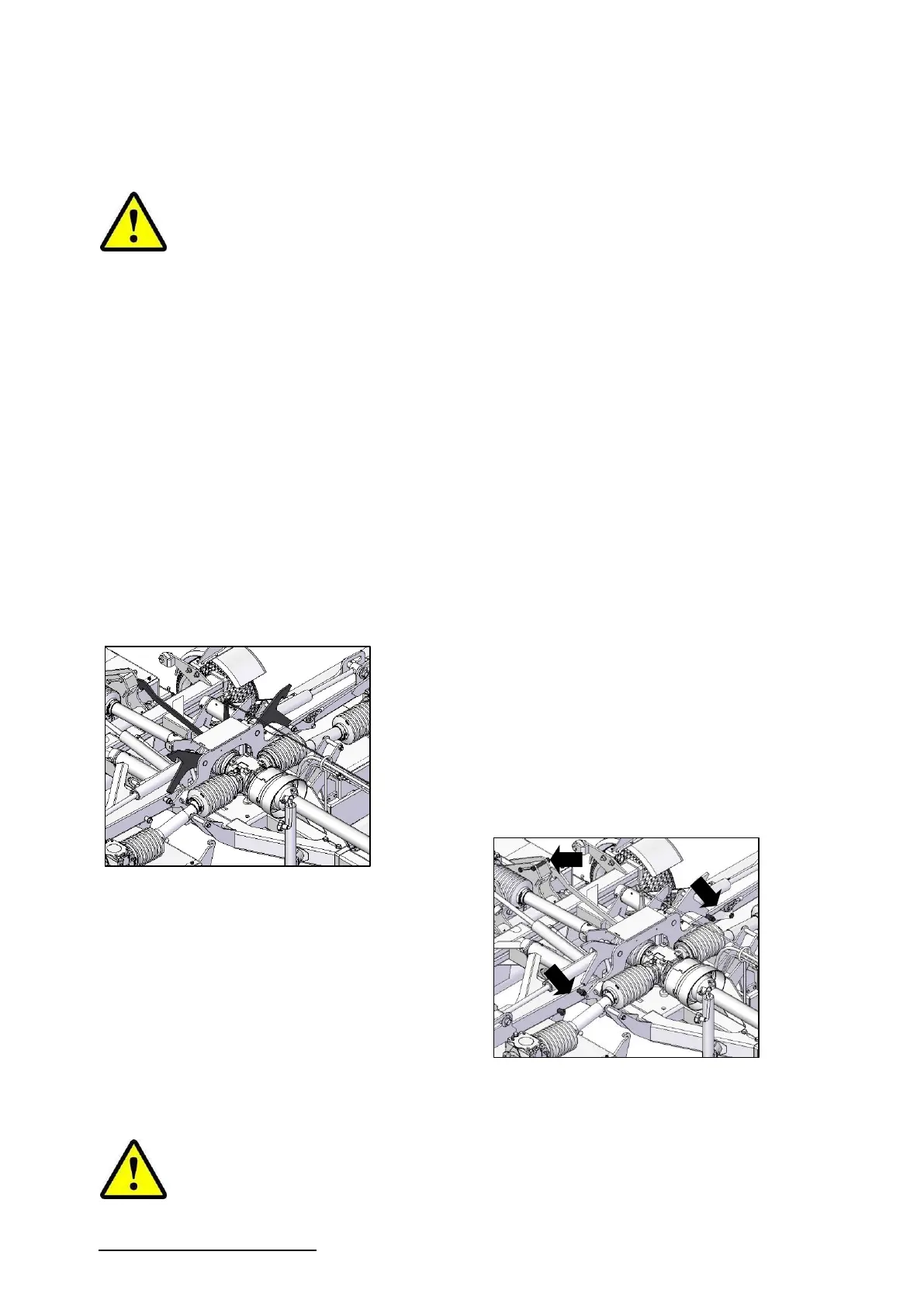

1. Transport lock configuration:

a. Each mower deck is connected to the mower’s central chassis with a hinged outrigger.

b. Hydraulic rams power the outriggers to lift the decks into the transport position.

c. Downward movement relies on gravity. Hydraulic power is not used to power the outriggers

down.

d. When fully raised, transport locks engage to secure the outriggers and mower decks.

e. Each transport lock consists of a steel latch which

hooks over a lock pin or bolt on the chassis.

f. As each outrigger approaches the raised position a

ramp on the hook rides up the lock pin before gravity

causes the hook to engage.

g. All three hooks are connected by a linkage which

allows them to be disengaged by pulling on a single rope

or operating the optional Remote Unlock controller.

h. The locks incorporate stops that allow the mower to

lift just clear of the ground while operating. This “kerb

jump” or “lift-and-turn” function is extremely useful

when operating in tight areas.

Loading...

Loading...