3. Replace the wheels:

a. Ensure the wheel stud and nut threads are clean.

b. Fit the wheel to the studs.

c. Fit the stud nuts with the tapered side to the wheel. Lightly tighten each nut following a

crossways pattern.

d. Lower the jack until some of the weight of the mower is on the wheel.

e. Fully tighten the wheel nuts to 75Nm (55 lb-ft) in a cross-ways pattern then check each nut

for tightness again.

f. Lower the jack to clear the machine and remove it.

4. Check the wheel bearings:

a. Check the wheel bearings monthly.

b. Jack the chassis up as described above until the tyre is just off the ground.

c. Rotate the wheel slowly to check for tightness or roughness.

d. If the wheel does not turn easily the bearings may be adjusted too tightly.

e. If roughness is detected the bearings must be dismantled, cleaned, inspected and replaced if

necessary. Consult your service manager or automotive repair centre.

f. Grasp the wheel at either side and move it firmly to check for any looseness in the bearings.

If there is more than 1mm (1/16”) of movement at the rim the wheel bearings may need to be

adjusted. Consult your service manager or automotive repair centre.

16j. Pitch & Roll Pivots.

1. General:

a. To articulate, the mower decks can “roll” to the left-and-right and “pitch” to front-and-rear.

Roll and pitch pivots need to be checked for tightness every 150 hours or monthly.

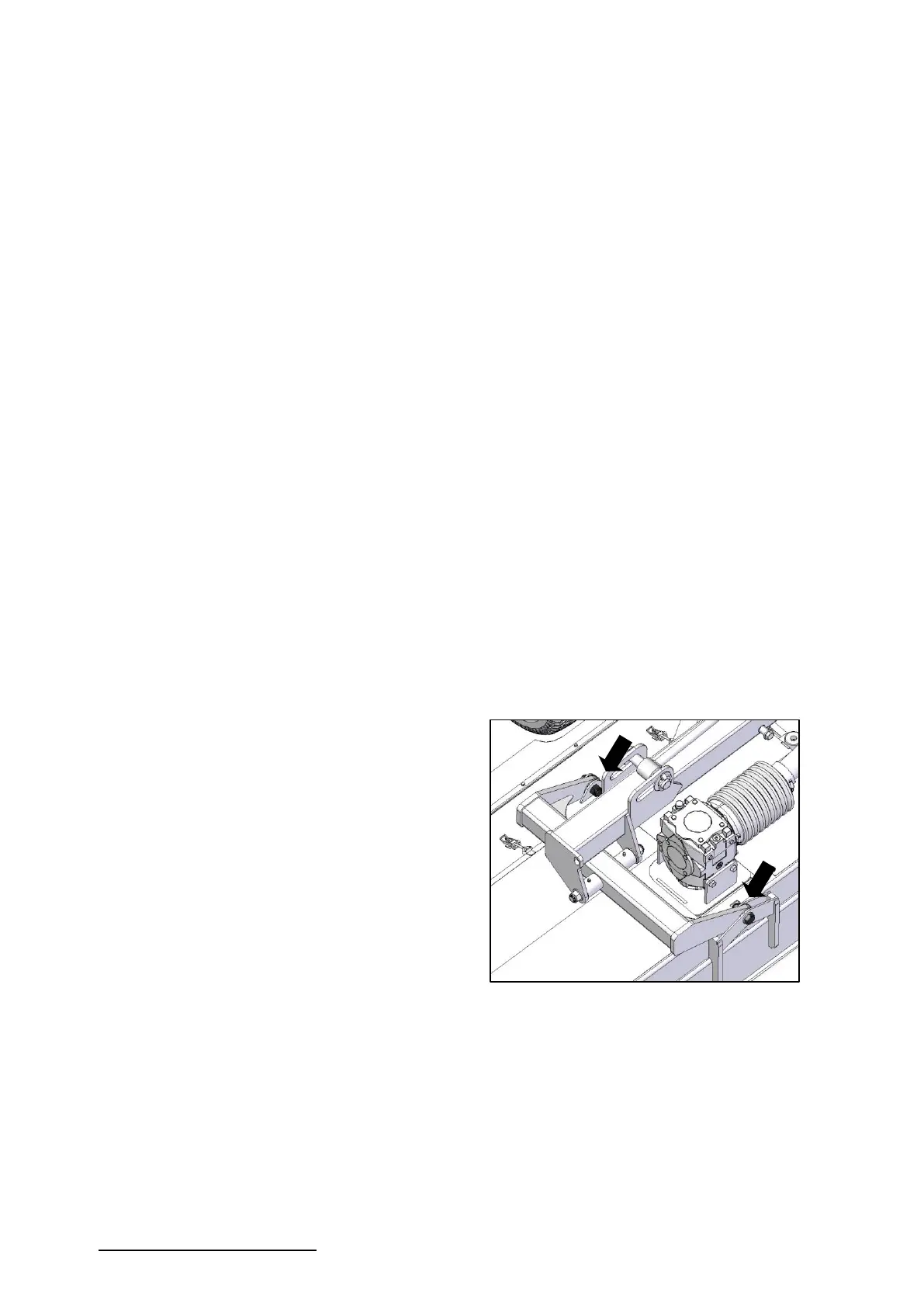

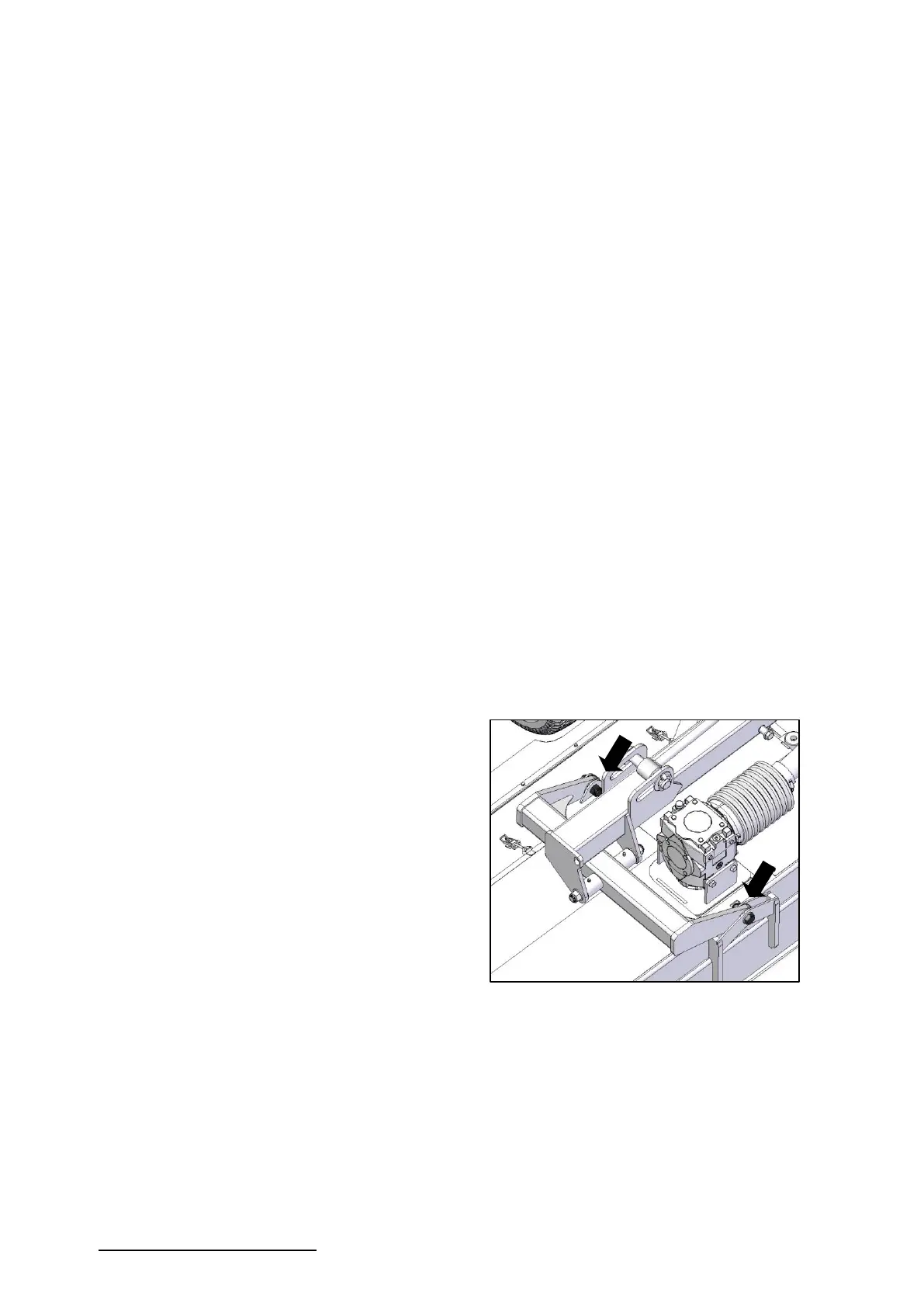

2. Check the roll pivots on all decks:

a. All decks have roll pivots, which are fixed by

the large bolts at the front and rear of the

superstructure.

b. Inspect for any signs of movement between

the bolt head and body and the nut and body.

c. The side decks use a 30mm spanner to

ensure the M20 bolts and nuts are tight

(200Nm or 148 lb-ft).

Loading...

Loading...