TRIMAX SNAKE S2 OPERATORS MANUAL

ENGLISH EDITION

©Trimax Mowing Systems (NZ) Ltd

www.trimaxmowers.com 52 27 March 2019

3. Set the skid height:

a. Use the mower to mow a section of turf.

b. Examine the finished job. If the finish is

unacceptable, the skid height will need to be

adjusted to suit.

c. Work on one mower deck at a time. Add one

washer to each stud on the skid on both

sides of the deck.

d. Mow another section of problematic terrain

and compare the finished job of the deck that

was changed with the job done by the other

mower decks.

e. Repeat the above steps to reach the best

compromise between bounce suppression

and turf damage.

f. Adjust the other mower deck skids to the same level.

g. When finished securely tighten all the mounting nuts.

16f. Greasing.

WARNING! DO NOT OVERGREASE THE ROLLER BEARINGS! Excessive

grease will dislodge the bearing seals and allow dirt and water to enter the

bearing. This will cause early bearing failure.

1. Grease types:

a. Use only lithium-based grease manufactured by a reputable company. Most "multi-purpose"

greases supplied by well-known companies are lithium or lithium complex based and should be

compatible with those used in Trimax products.

b. Greases formulated from bases other than lithium may react or completely break down when

mixed, even in very small quantities. In particular, do not use greases containing graphite.

c. If there are any doubts concerning the composition of any grease being considered for use in this

Trimax product consult your lubricant supplier or purchase a suitable product from a multi -national

company.

d. Cleanliness is essential when working with grease and oil. Clean the grease gun nozzle and each

grease fitting before applying grease.

e. The quantity of grease is described by the number of “pumps” or “shots”. One pump is defined as

the quantity of grease delivered by one pump of a lever-action grease gun, while one shot is that

delivered in one cycle of an air-operated power grease system. One shot is typically equivalent to

four pumps.

2. Grease roller bearings:

a. Lubricate every 8 hours or daily.

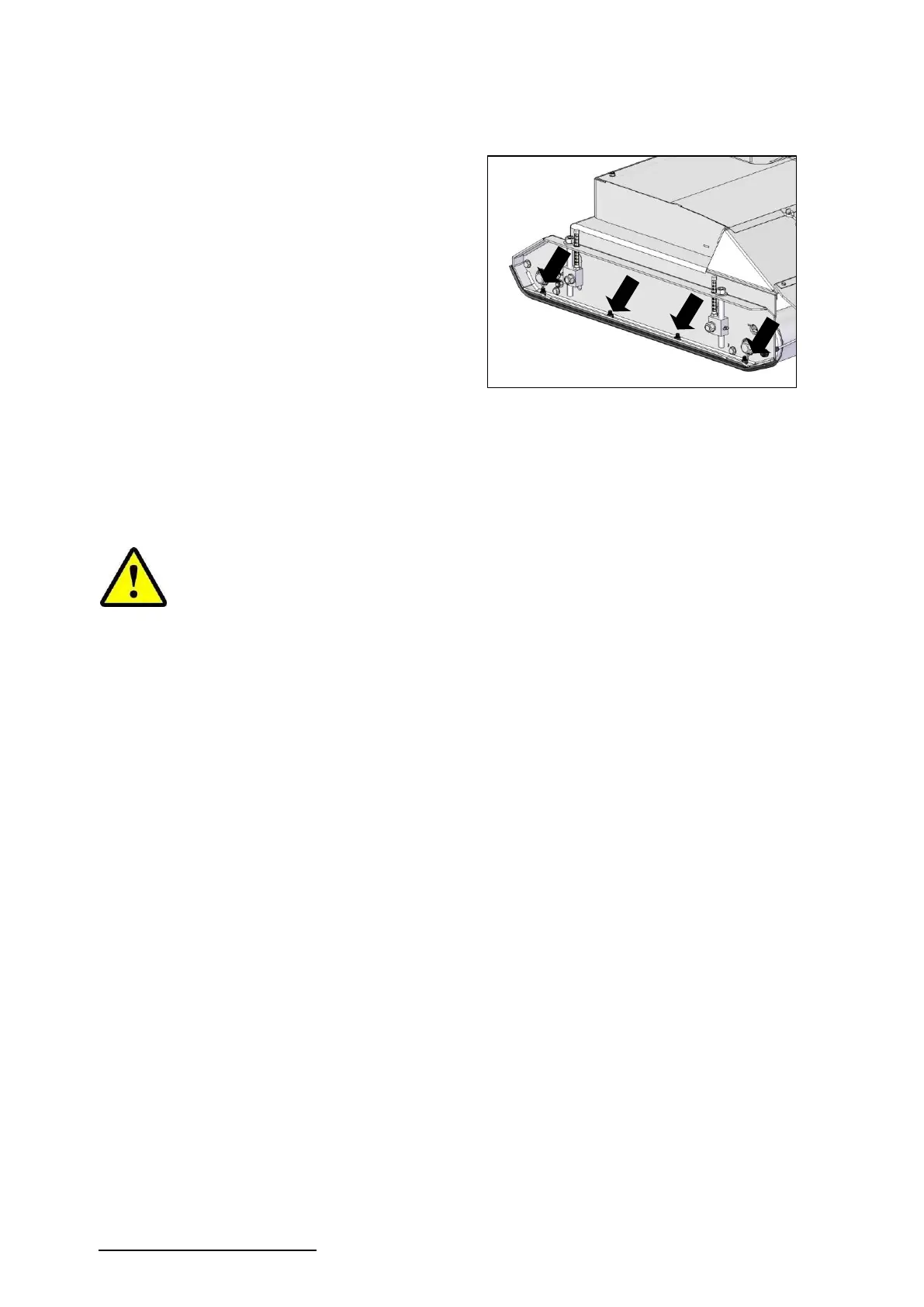

b. All but two grease points are located just inside an access hole in the side channels as shown.

c. The roller bearing on the right-hand side of front roller of the rear deck is accessed from above

when the rear deck is in its lowered position

d. The roller bearing on the left-hand side of the front roller on the rear deck is accessed from the rear

of the machine with the rear deck in the raised position.

e. Apply no more than 2 pumps of multi-purpose grease to each point.

Loading...

Loading...