TRIMAX SNAKE S2 OPERATORS MANUAL

ENGLISH EDITION

©Trimax Mowing Systems (NZ) Ltd

www.trimaxmowers.com 55 27 March 2019

2. Change the gearbox oil:

a. Every 1,000 hours drain each gearbox.

b. There is a drain plug in the gearbox, but it can be difficult to get to. Use an oil suction gun to

remove all the oil through the breather plug. Suction guns are available from larger

automotive supply companies.

c. Dispose of oil according to local laws and regulations.

d. Re-fill with EP90 gear oil. Capacities are:

I. Chassis gearbox, 1.4 litres (2.46 UK pints, 2.96 US pints)

II. Mower deck gearboxes, 1.4 litres (2.46 UK pints, 2.96 US pints). Do not overfill or

overheating and oil leaks will result.

e. Refit the breather and tighten securely.

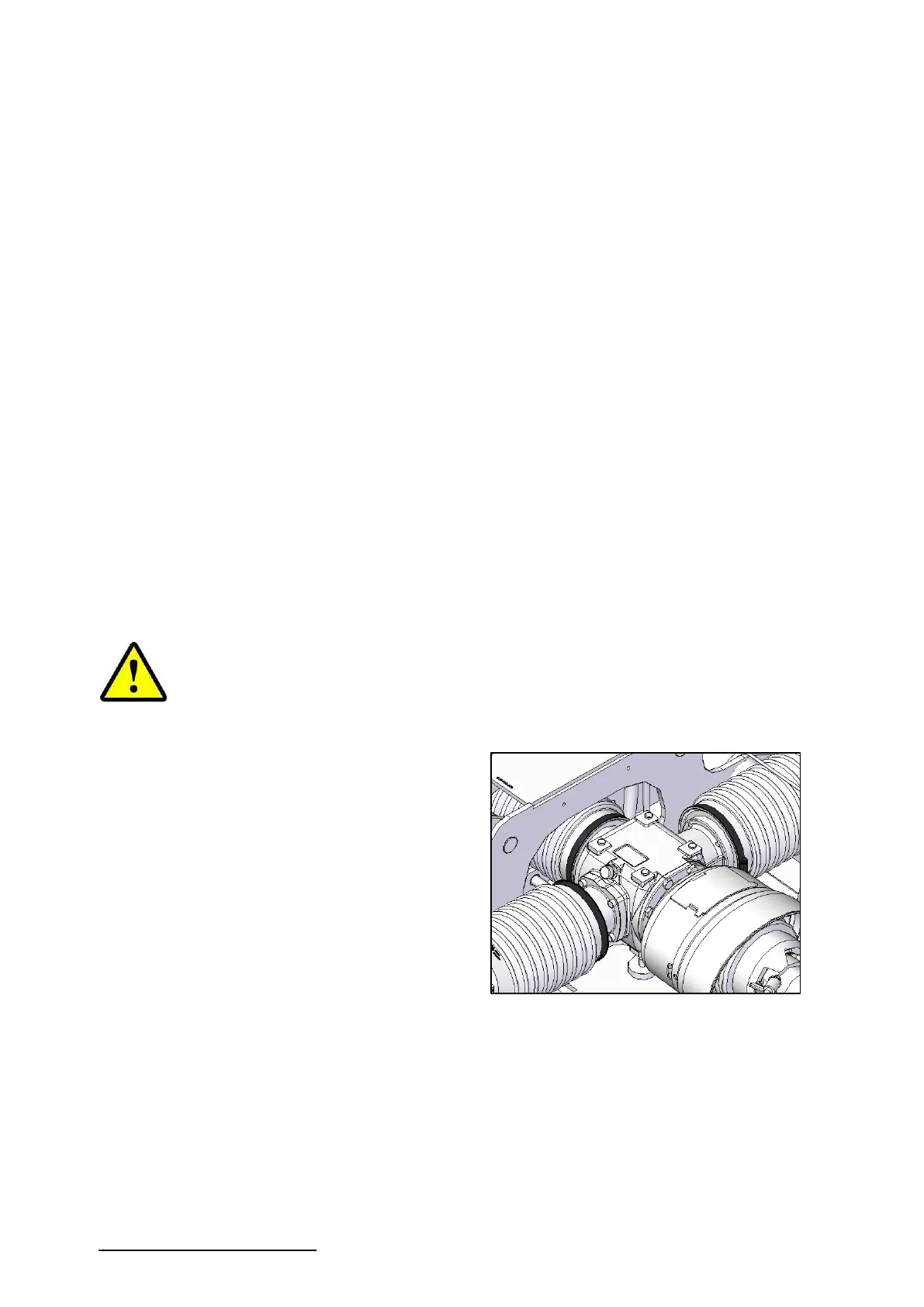

16h. Driveshaft Maintenance.

1. General:

a. The driveshafts that connects the tractor PTO output to the primary gearbox and the primary

gearboxes to the mower deck gearboxes are complex pieces of equipment. Regular

maintenance is essential.

b. Driveshaft tubes must always be able to telescope freely, or serious damage will result.

c. Driveshafts for Trimax mowers may be supplied by various manufacturers.

d. Maintenance instructions may be attached to the driveshaft or included with this operator’s

manual. Follow the manufacturer’s guidelines. If they are not available use the following

guide.

2. Guide to servicing all driveshafts:

a. It is easiest to remove the driveshaft from the

machine for servicing.

b. Work on one driveshaft at a time so the same

parts are always assembled together.

c. Undo the large jubilee clip on the mower deck

gearbox and slide the rubber concertina off the

gearbox.

d. Repeat for the opposite end.

e. After greasing, refit the smaller cover tube to the

chassis gearbox end. This helps prevent water

and dirt running between the tubes when the

decks are in the raised position.

f. Fit both concertina covers back on loosely.

Ensure the slipper bearing grease holes are

facing upwards before tightening jubilee clips.

Loading...

Loading...