TRIMAX SNAKE S2 OPERATORS MANUAL

ENGLISH EDITION

©Trimax Mowing Systems (NZ) Ltd

www.trimaxmowers.com 58 27 March 2019

16i. Wheel & Tyres.

DANGER! Tyre and rim parts can explode if tyres are over-inflated causing

serious injury or death. Always maintain the correct tyre pressure. Do not

inflate the tyres above the recommended pressure.

DANGER! Never weld or heat a wheel and tyre assembly. The heat can

cause an increase in air pressure resulting in a tyre explosion. Welding can

structurally weaken or deform the wheel.

CAUTION! When inflating tyres use a clip-on fitting and extension hose long

enough to allow you to stand to one side and NOT in front of or over the tyre

assembly.

1. Check tyre pressures:

a. Check the road wheel tyre pressures weekly.

b. Tyres should be inflated to the pressures shown in the table. NEVER EXCEED THE

MAXIMUM INFLATION PRESSURE!

c. Inspect the tyres for wear, cuts, cracking, loose or missing stud nuts or other damage. Repair

or replace if necessary.

2. To remove the wheels:

a. Park the mower on level ground.

b. The mower decks can be raised or lowered, with the mower attached to the tractor or on its

own.

c. If the mower is to remain connected to the tractor, engage the parking brake, place all

controls in neutral, stop the engine and remove the ignition key before proceeding further.

d. Chock the wheel not being removed to prevent movement when jacking the other wheel up.

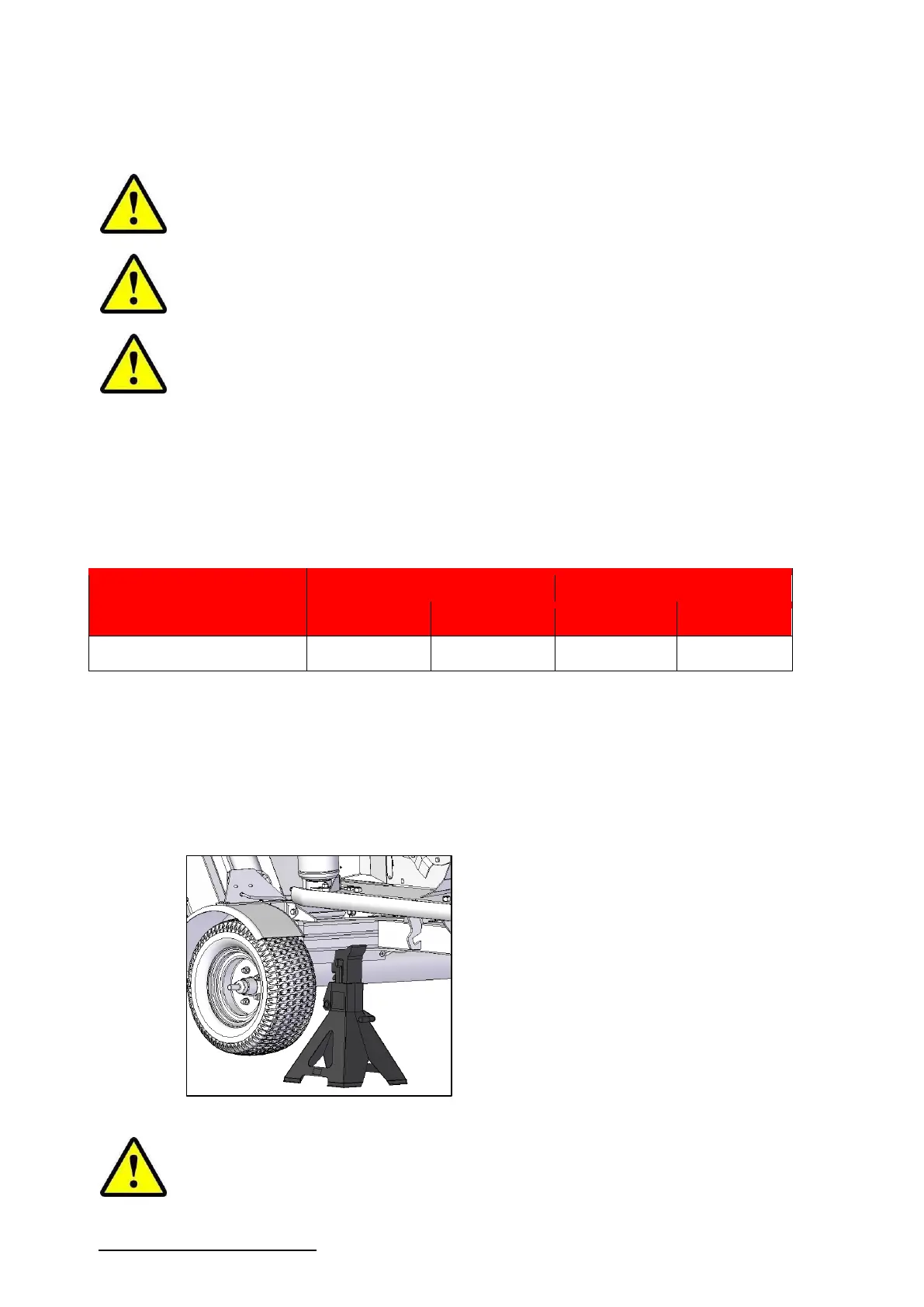

e. Use a suitable jack with a capacity of at

least 1,000kg (1 ton).

f. Place the jack beneath the square steel

tube that houses the suspension and jack the

chassis up to take part of the weight. Do not

lift the wheel clear of the ground at this stage.

g. Use a wheel brace or a 21mm or 13/16”

socket to loosen the wheel nuts. Turn them

anti-clockwise to loosen. Do not remove the

nuts.

h. Jack the wheel clear of the ground.

i. Remove the wheel nuts and the wheel.

DANGER! If the mower must be left jacked up and unattended while the

tyre is being repaired place blocks or a suitable stand beneath the axle.

Loading...

Loading...