TRIMAX SNAKE S2 OPERATORS MANUAL

ENGLISH EDITION

©Trimax Mowing Systems (NZ) Ltd

www.trimaxmowers.com 63 27 March 2019

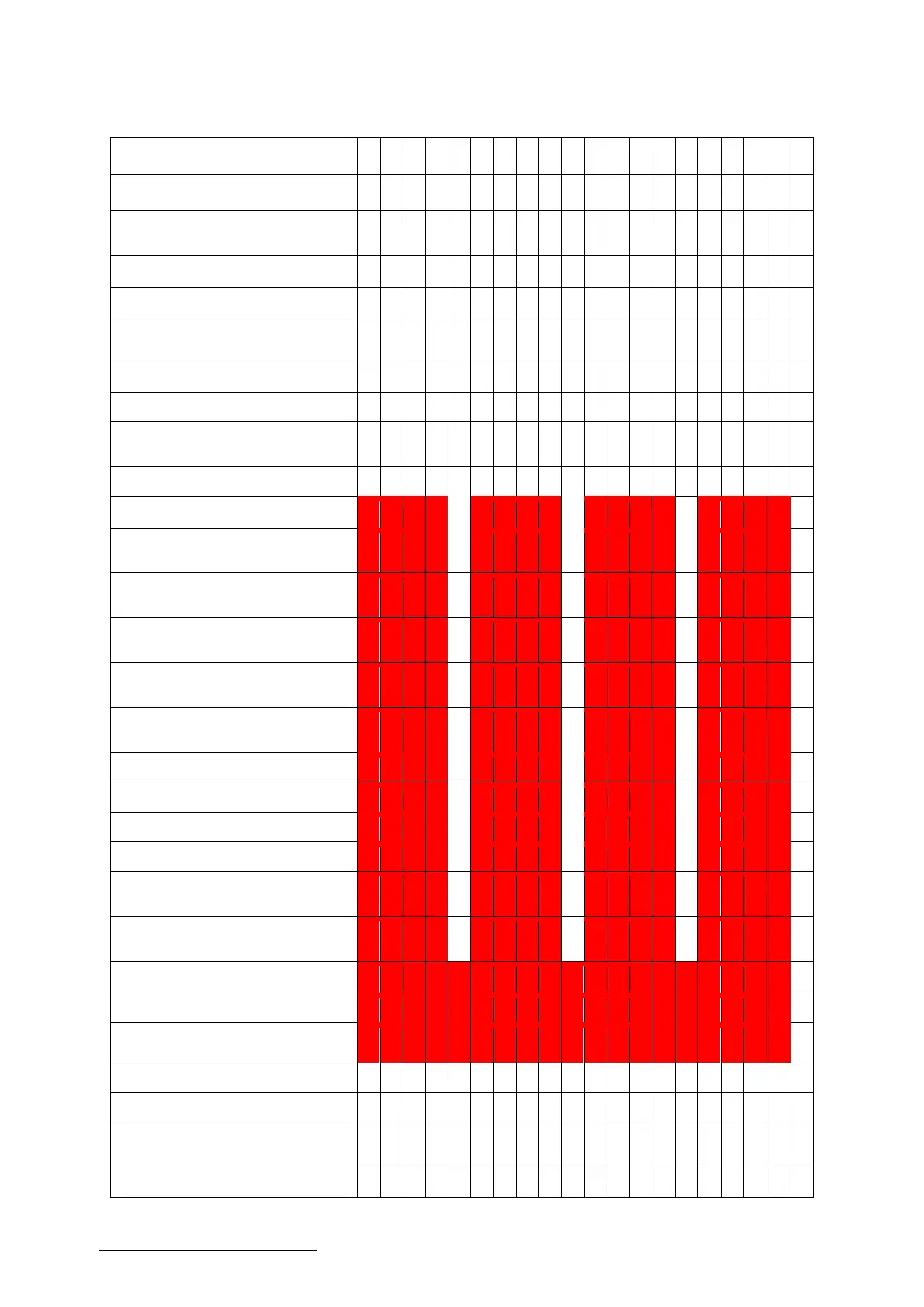

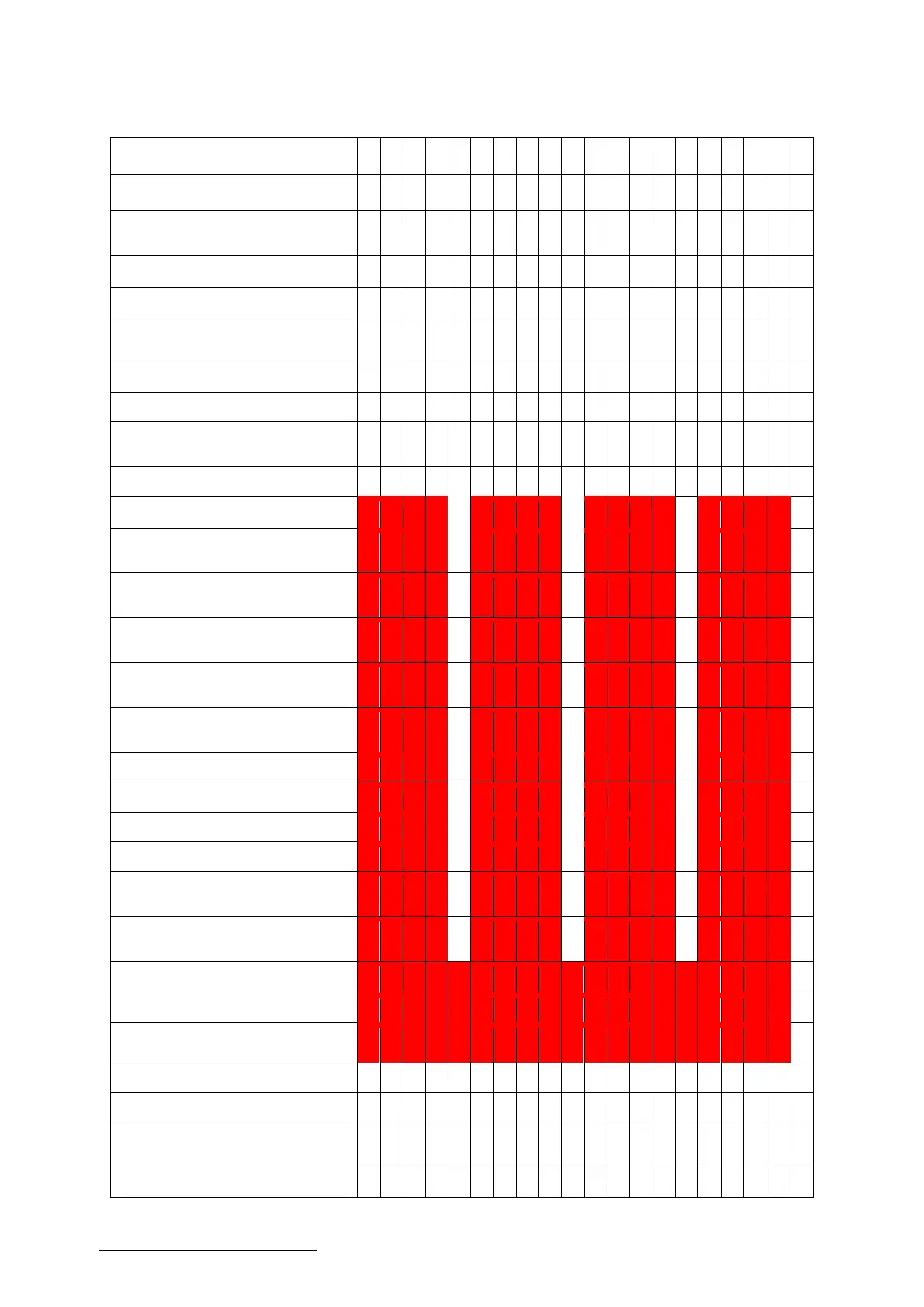

Grease roller bearings (12)

Check drive belt tension, adjust if

reqd. (3-5)

Check all fasteners and safety devices

Check fling-tip blade bolts for tightness

(18-22)

Check transport lock operation (3)

Grease primary driveshaft CV joint (4

grease points)

Grease mower deck driveshaft

universal joints (6)

Grease all driveshaft telescoping

tubes (4)

Grease all driveshaft cover bearings

(8)

Grease outrigger hinge bushes (6)

Check drive belt condition (3-5)

Grease mower deck roll pivots (6)

Grease mower deck pitch pivots (4)

Check for gearbox oil leaks (4)

Check road wheel tyres and pressures

(2)

Check road wheel stud nuts for

tightness (10)

Every 150 hours or monthly

Check transport wheel bearings (2)

Check tightness of roll & pitch pivots

(3)

Every Season or As Required

Grease height adjuster blocks (12)

Check all driveshaft universal & CV

joints for wear (4)

Loading...

Loading...