Forklift operation at project site

The forklift operation at project site refers to the transportation of modules between the storage site

and the installation site after they arrived at the project storage site.

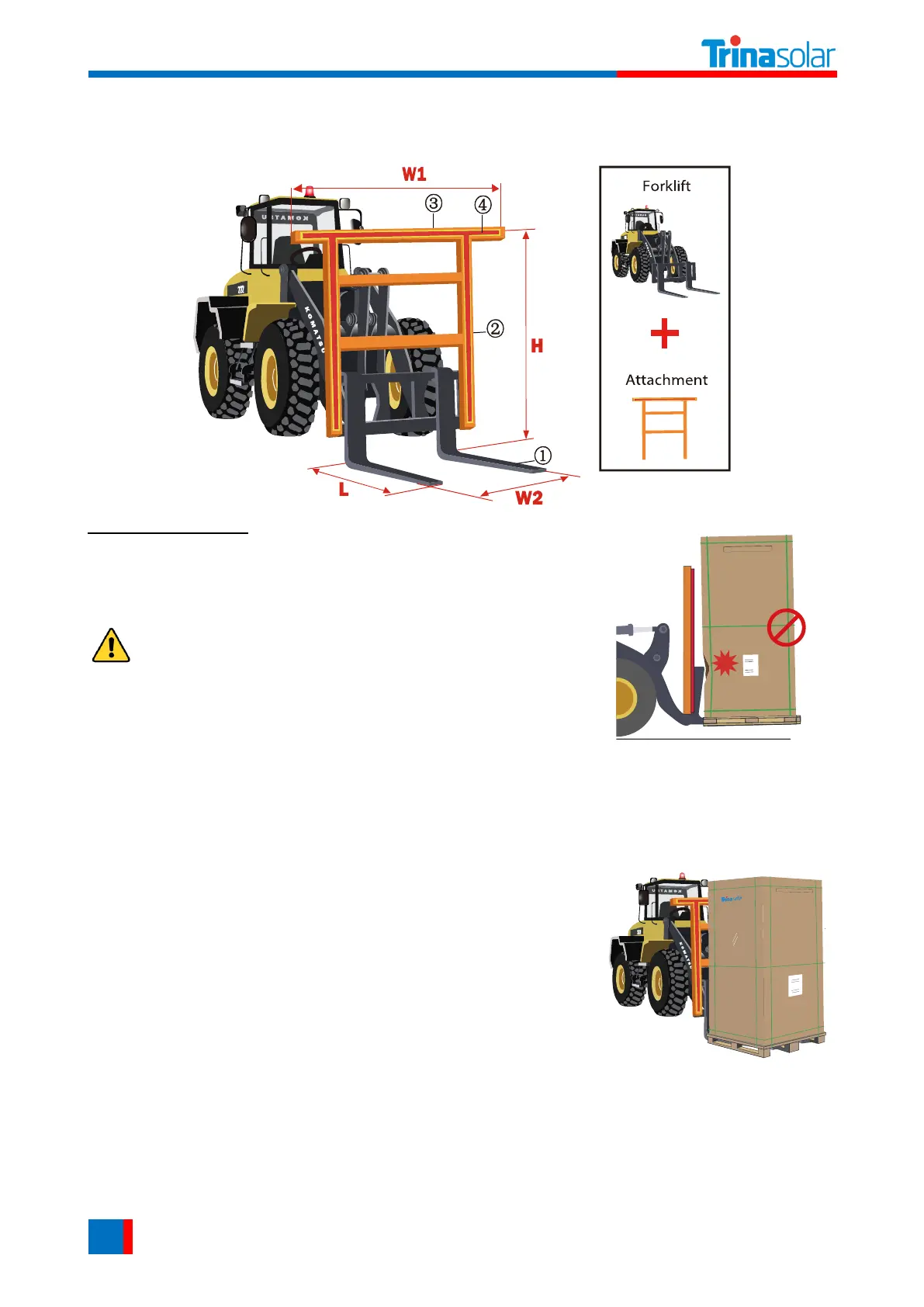

Forklift requirements:

Vertical portrait package

Please use forklifts with a rated lifting capacity of ≥ 3.5 tons to load

and transport the modules.

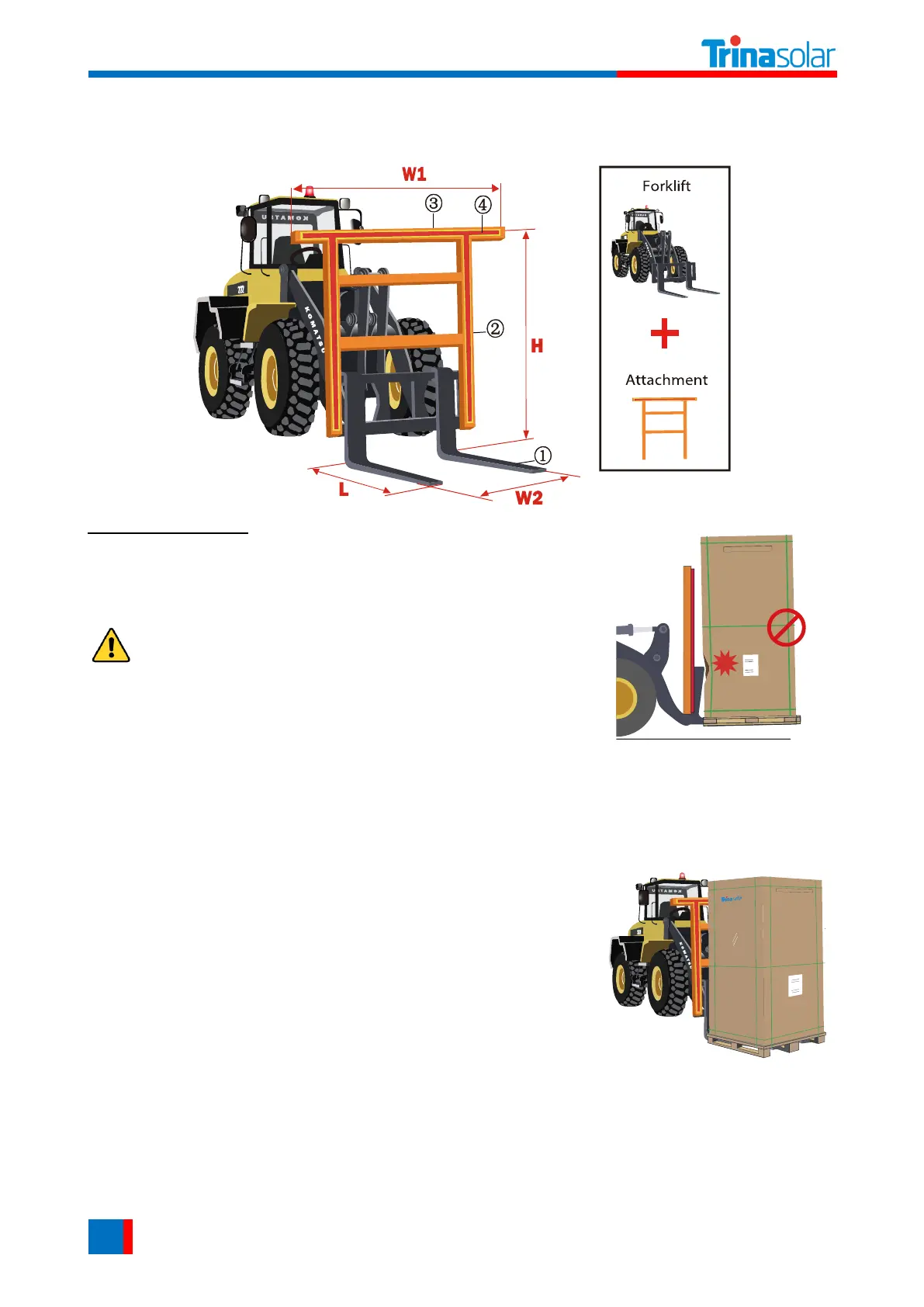

Do not allow the convex part of the fork to directly contact with the

carton or modules to prevent damage to the modules.

① Forks

The fork length (L) should ≥ 1.0 m.

The forks distance (W2) should be adjusted to the maximum

position without any interference to the pallet.

② Backrest

The backrest length (H) should ≥ 1.7 m; the backrest width (W1)

should ≥ 1.5 m.

The backrest shall perpendicular to the fork, and the structure must

be firm (withstand pressure ≥ 15 kN). When the entire module

package leans on the backrest, the backrest shall not be deformed

due to pressure.

③

Beam

④ Buffer material

The contact position between the top beam and the module package

should be fixed with a buffer material (preferably silicone, rubber,

EPE) to prevent the forklift from damaging the modules.

Loading...

Loading...