Thermostatic shower pole

5

Isolating switch or

pull cord switch

(both fused at 3A)

Hot water

cylinder

Shower

pole

Service

valve

Cold supply

Hot supply

Alternative

supply

Cold

water

mains

supply

Ring main

Drain

valve

Gate

valve

Service

valve

Other

draw-offs

Stop valve

Cold water

cistern

Pump

Minimum head

Flow

Return

Boiler

Blender

valve

Cold mains supply

Hot

water

Stop tap

Expansion

vessel

Pressure

reducing valve

Service

valves

Shower pole

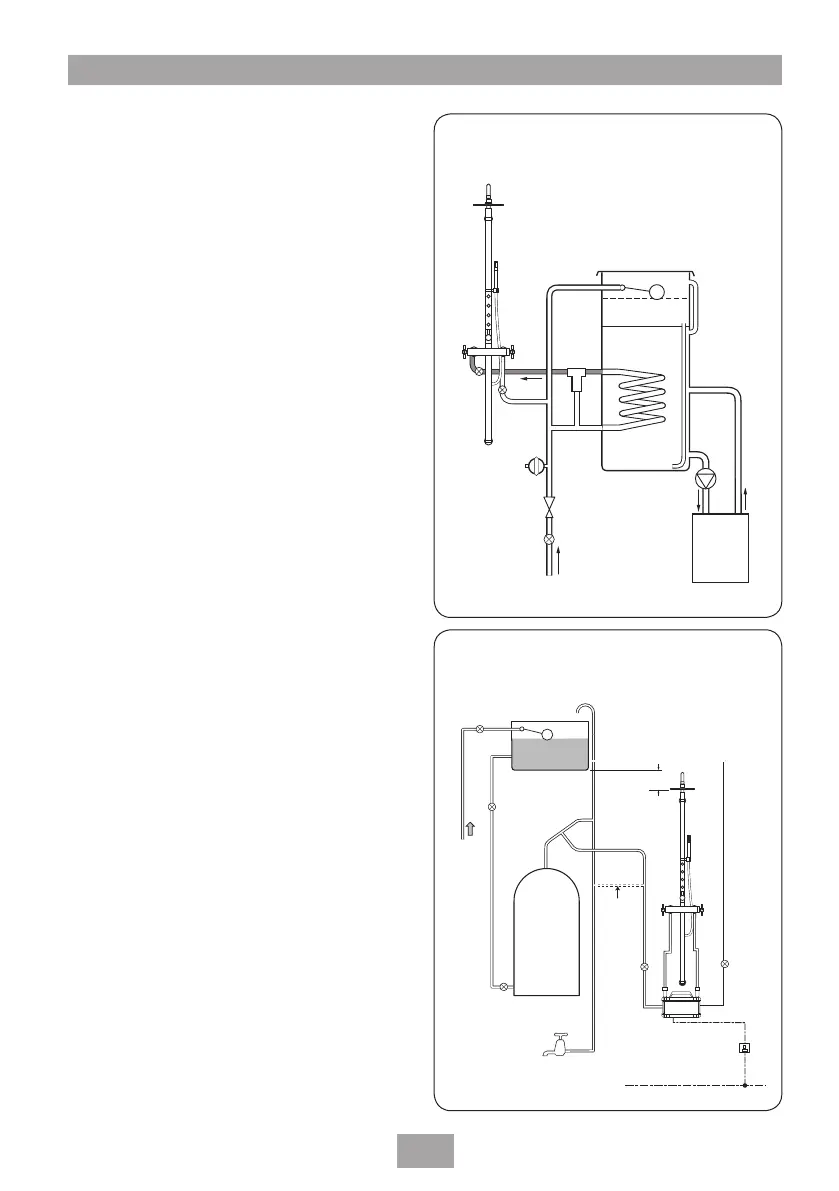

Fig.4 (diagrammatic view – not to scale)

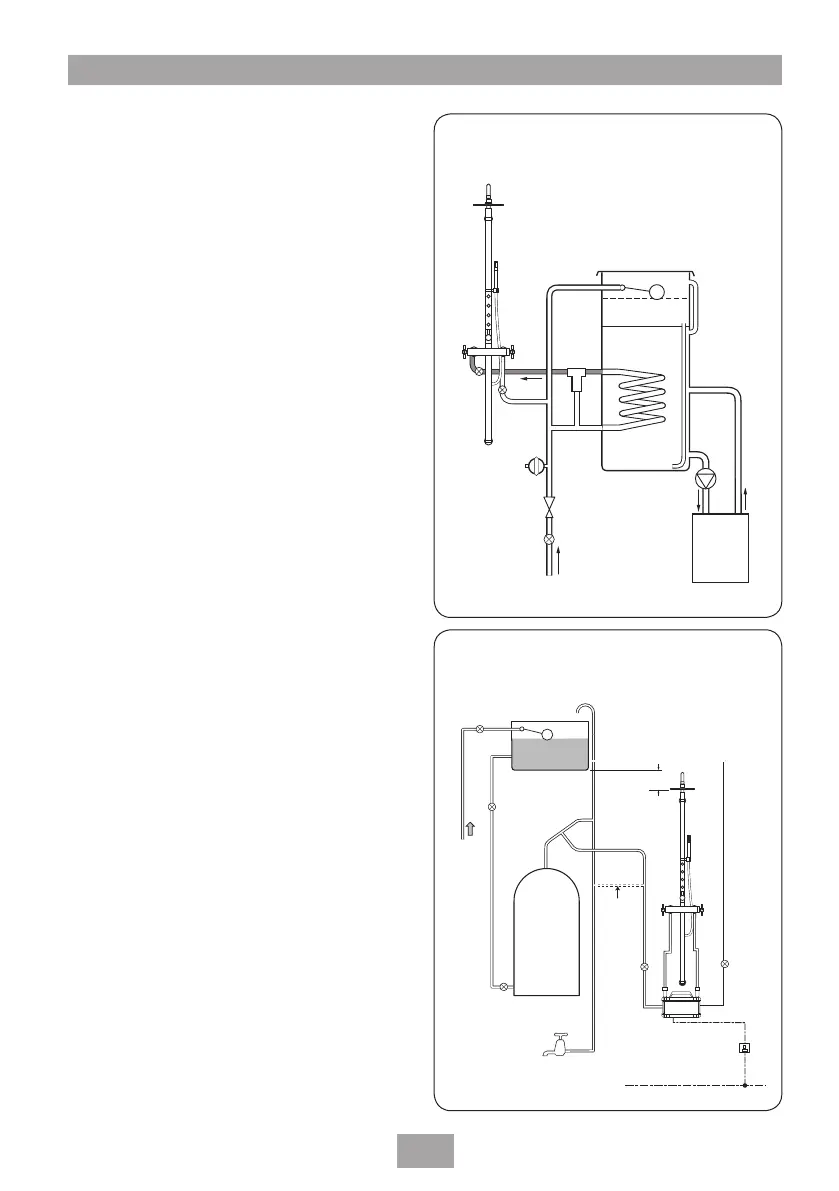

Fig.5 (diagrammatic view – not to scale)

c) Mains pressurised thermal store

systems

(fig.4)

Packages of this type, fitted with a tempering

valve (blender valve) can be used. A drop tight

pressure reducing valve MUST be fitted if the

supply pressures exceed 5 bar running.

An expansion vessel (shown in fig.4) MUST be

fitted, and regularly maintained, to make sure

the unit is not damaged by excess pressures.

This may already be installed externally or

internally within the thermal store (check with

thermal store manufacturer).

d) Pumped gravity fed systems (fig.5)

The shower MUST be fed from a cold water

cistern and hot water cylinder providing

nominally equal pressures.

The mixer unit may be used with a gravity

fed system with a pump to boost pressures

as shown. There will be a minimum head

requirement which will be specified in the

installation and operation instructions supplied

by the pump manufacturer.

Loading...

Loading...