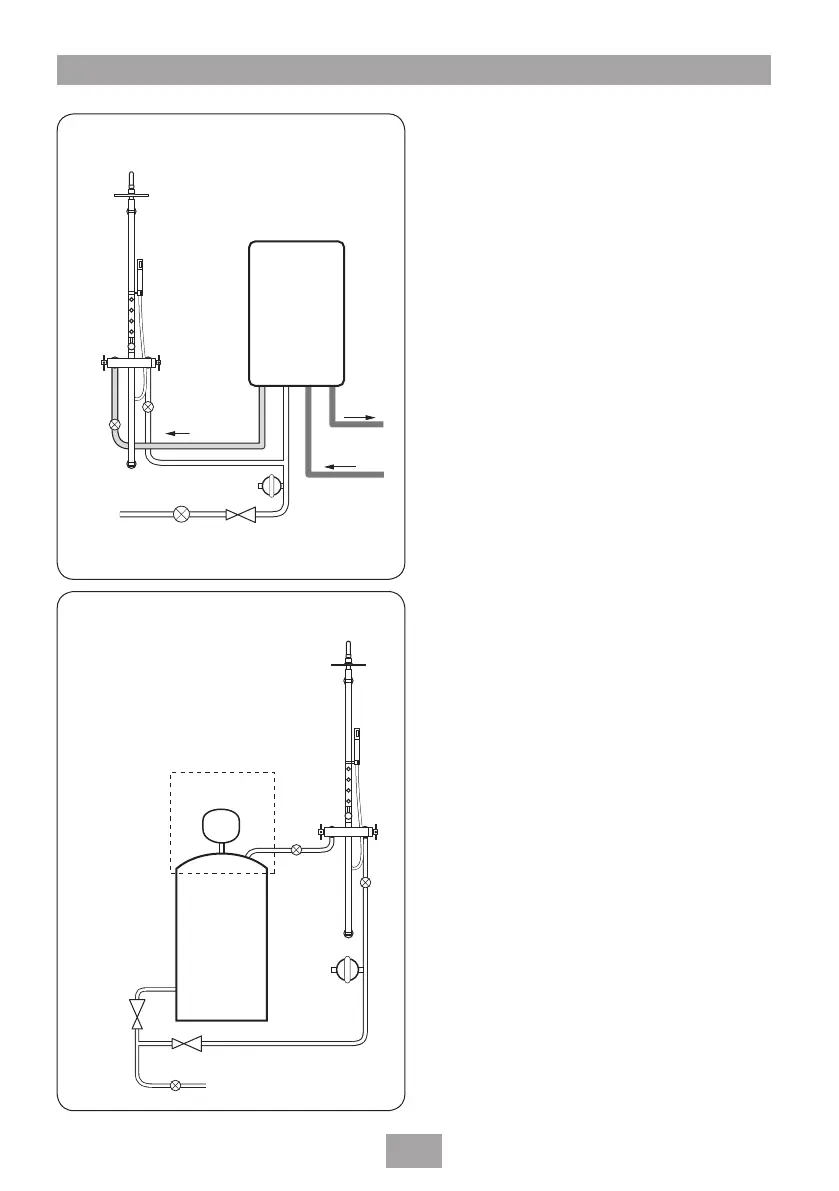

Thermostatic shower pole

4

Service

valves

Balanced cold mains supply

Cold mains supply

Shower pole

Expansion

vessel

Pressure

reducing

valves

Stop tap

Unvented

hot water

storage unit

Safety devices

not shown

Fig.3 (diagrammatic view – not to scale)

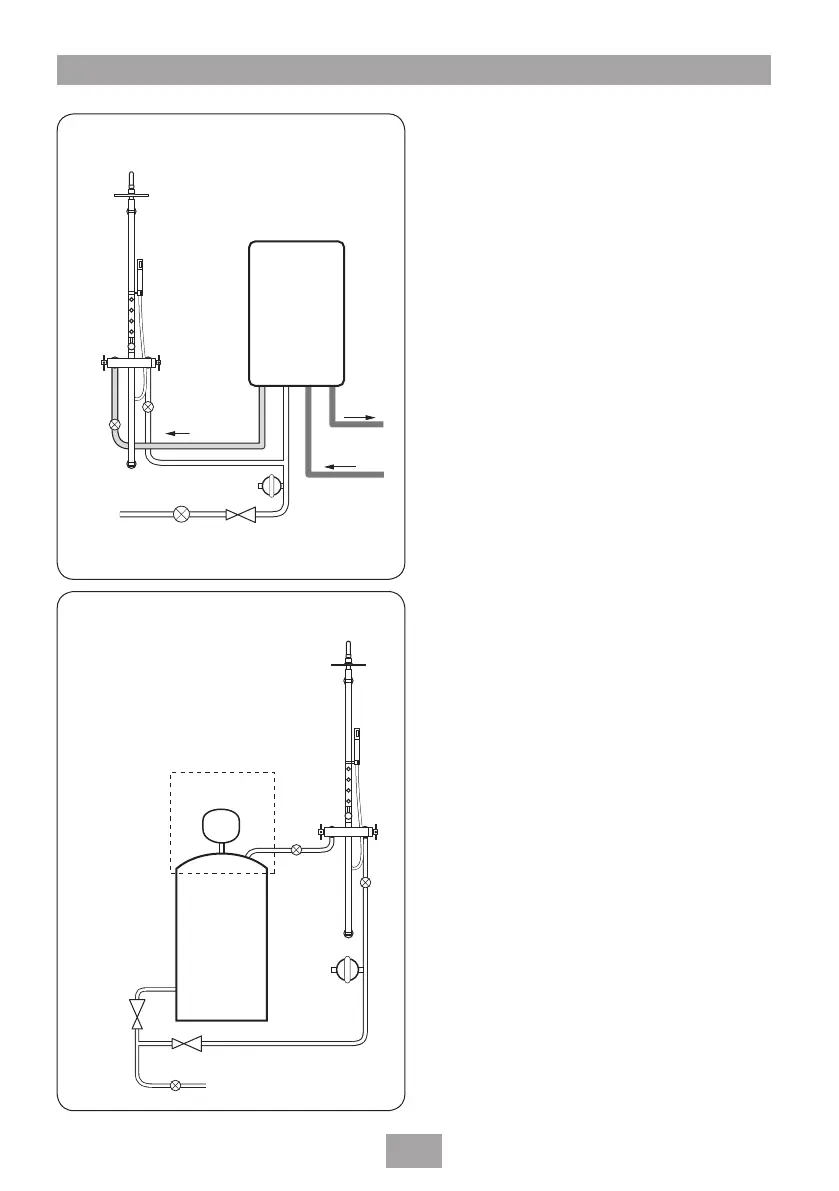

CH flow

Cold

mains

supply

Hot water

CH return

Service

valves

Shower pole

Stop

tap

Expansion

vessel

Pressure

reducing valve

Combination

boiler

Fig.2 (diagrammatic view – not to scale)

TYPICAL SUITABLE INSTALLATIONS

a) Instantaneous gas-heated systems,

e.g. combination boilers

(fig.2)

The shower MUST be installed with a multipoint

gas water heater or combination boiler of a fully

modulating design (i.e. to maintain relatively

stable hot water temperatures).

A drop tight pressure reducing valve MUST

be fitted if the supply pressures exceed 5 bar

running.

An expansion vessel (shown in fig.2) MUST be

fitted, and regularly maintained, to prevent the

shower being damaged by excess pressures. This

may already be installed within the boiler (check

with manufacturer) and is in addition to the

normally larger central heating expansion vessel.

The layout and sizing of pipework MUST be

such that nominally equal inlet supply pressures

are achieved and the effects of other draw-offs

are minimised. The hot supply temperature

MUST remain a minimum of 10°C hotter than

the required blend temperature for optimum

performance.

b) Unvented mains pressure systems

(fig.3)

The shower can be installed with an unvented,

stored hot water cylinder.

For systems with no cold water take off after the

appliance reducing valve, it will be necessary to

fit an additional drop tight pressure reducing

valve when the mains pressure is over 5 bar.

The drop tight pressure reducing valve must be

set at the same value as the unvented package

pressure reducing valve.

Note: An additional expansion vessel (fig.3)

may be required if a second pressure reducing

valve is installed. This does not apply to

packages with a cold take off after the pressure

reducing valve to the cylinder.

The layout and sizing of pipework MUST be

such that nominally equal inlet supply pressures

are achieved and the effects of other draw-offs

are minimised.

Loading...

Loading...