- 29 -

Adding cutting conditions

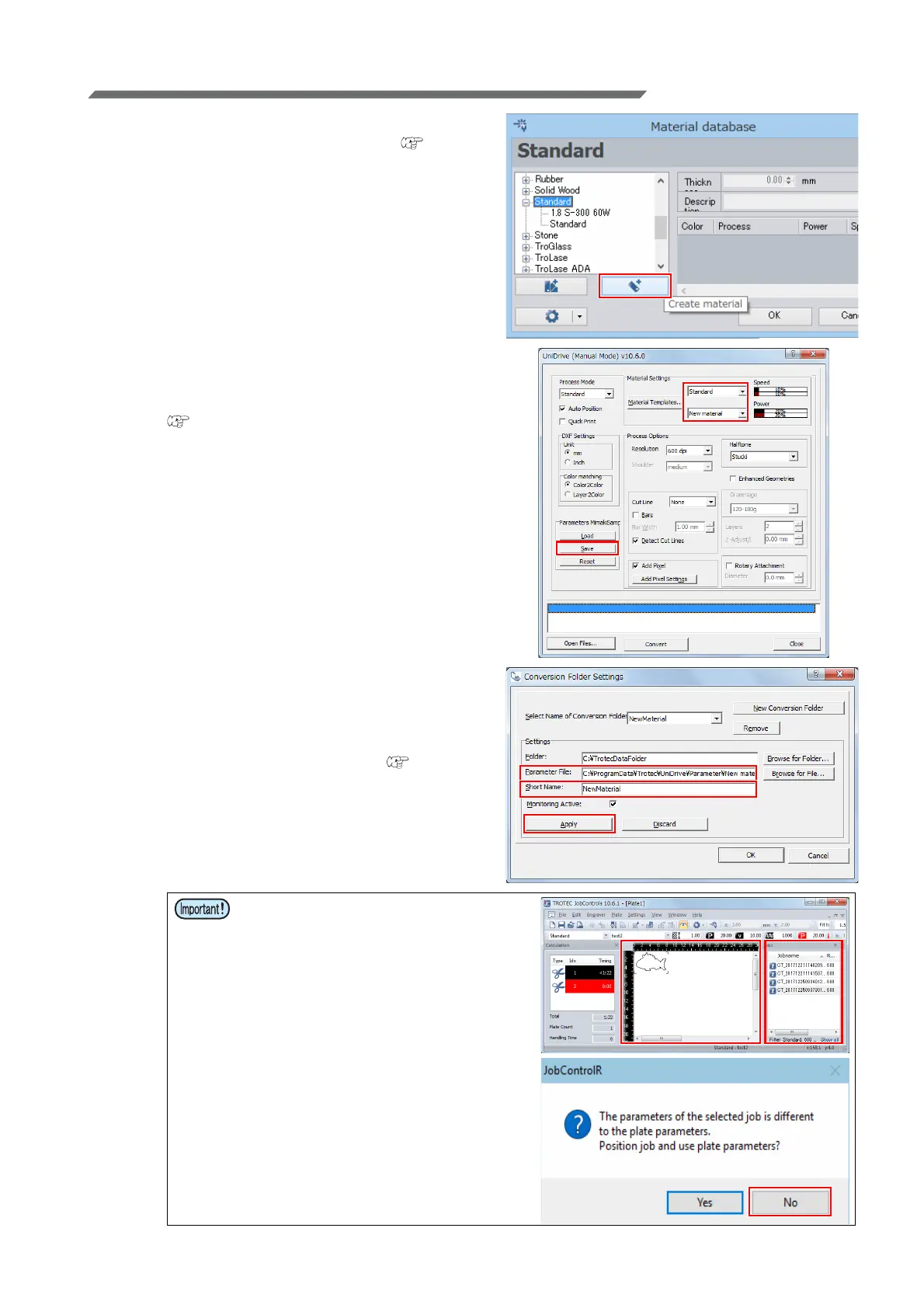

1. Create a new material in the Trotec Job-

Control [Material database]. ( P.10

"Register the new material.")

• The newly created material template also applies

to data already loaded in Trotec JobControl.

2. In the Trotec UniDrive [Convert Manually]

- [UniDrive (Manual Mode)] dialog, create

a parameter file for the new material.

( P.11 "Create a cutting conditions

parameter file.")

3. In the Trotec UniDrive [Conversion Fold-

ers] - [Conversion Folders Settings] dia-

log, create a new conversion folder by

setting the parameter file of the new

material created in step 2. ( P.13

"Associate the conversion folder with the

cutting conditions parameter file (Trotec

UniDrive)")

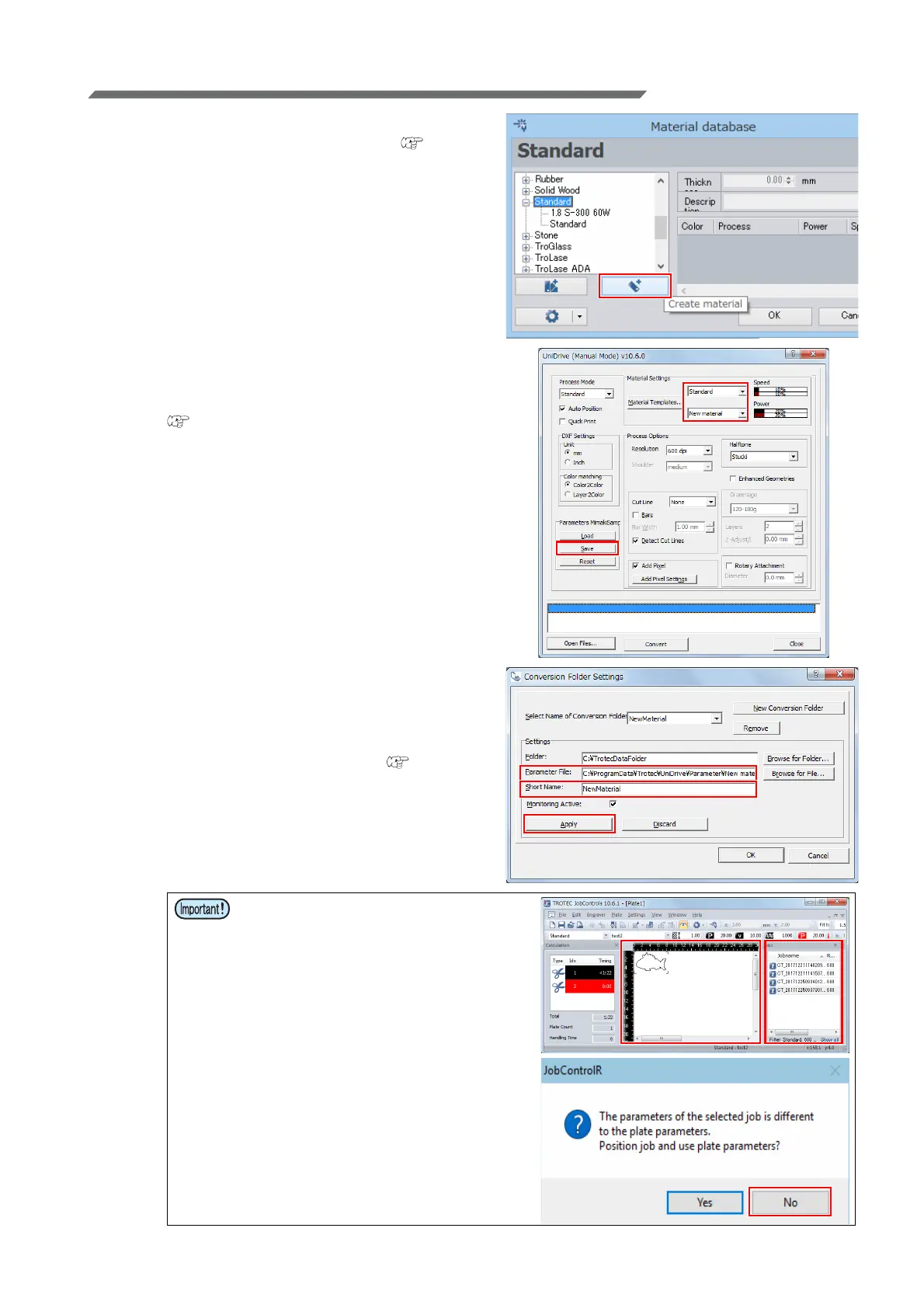

• If data that has an existing material

template is on the Trotec JobControl

view, it is not possible to reposition this

data by applying a different material

template.

If the message shown on the bottom

right appears, click the [No] button.

Delete the data on the JobControl view,

or drag and drop it back into the job list

on the right side of the screen. It is then

possible to reposition the data with the

new material template applied.

Loading...

Loading...