Calibration

Refer to the General section for dismantling instructions and safety precautions. Normal

calibration is done without opening the instrument.

Allow 10 minute warm-up before commencing calibration.

Refer to the User Manual for detailed operation of these power supplies.

Equipment Required

A 5.5 digit multimeter with better than 0.02% accuracy on dc volts and better than 0.12%

accuracy on dc current (to 5A); alternatively use a precision shunt for current measurement.

Calibration

To enter calibration press

shift

#, 99. If the instrument is a long way out of calibration or has

been repaired, the default calibration values should be loaded first by pressing shift

#, 91.

Pressing Escape at anytime will abort the calibration procedure and revert to the stored

calibration values.

Having entered calibration mode, follow the table below. To increment to the next step press OK.

The calibration must be done in sequence. At the end of calibration press OK to store the

calibration. The instrument automatically sets the range and settings at each step.

Use the spin-wheel to adjust calibration; holding down the

Jog Off

key will give x100

increments to speed up calibration. Pressing shift

will show the calibration value.

On triple units (QL355T and QL355TP) calibrate both output 1 and output 2.

There are two internal adjustments which are factory set and will normally only require adjustment

if a component has been changed in the associated area. If this is so proceed as follows. VR1

and VR2 are both located near the top of the control pcb. They are accessible from both sides of

the board. Turn them both fully clockwise as viewed from the component side, fully anti-clockwise

as viewed from the solderside. Adjustment is done with the output set to off. Connect an ammeter

across the output terminals and adjust VR1 for +1mA. Remove ammeter and connect voltmeter

and adjust for VR2 –10mV. (minus or negative 10mV).

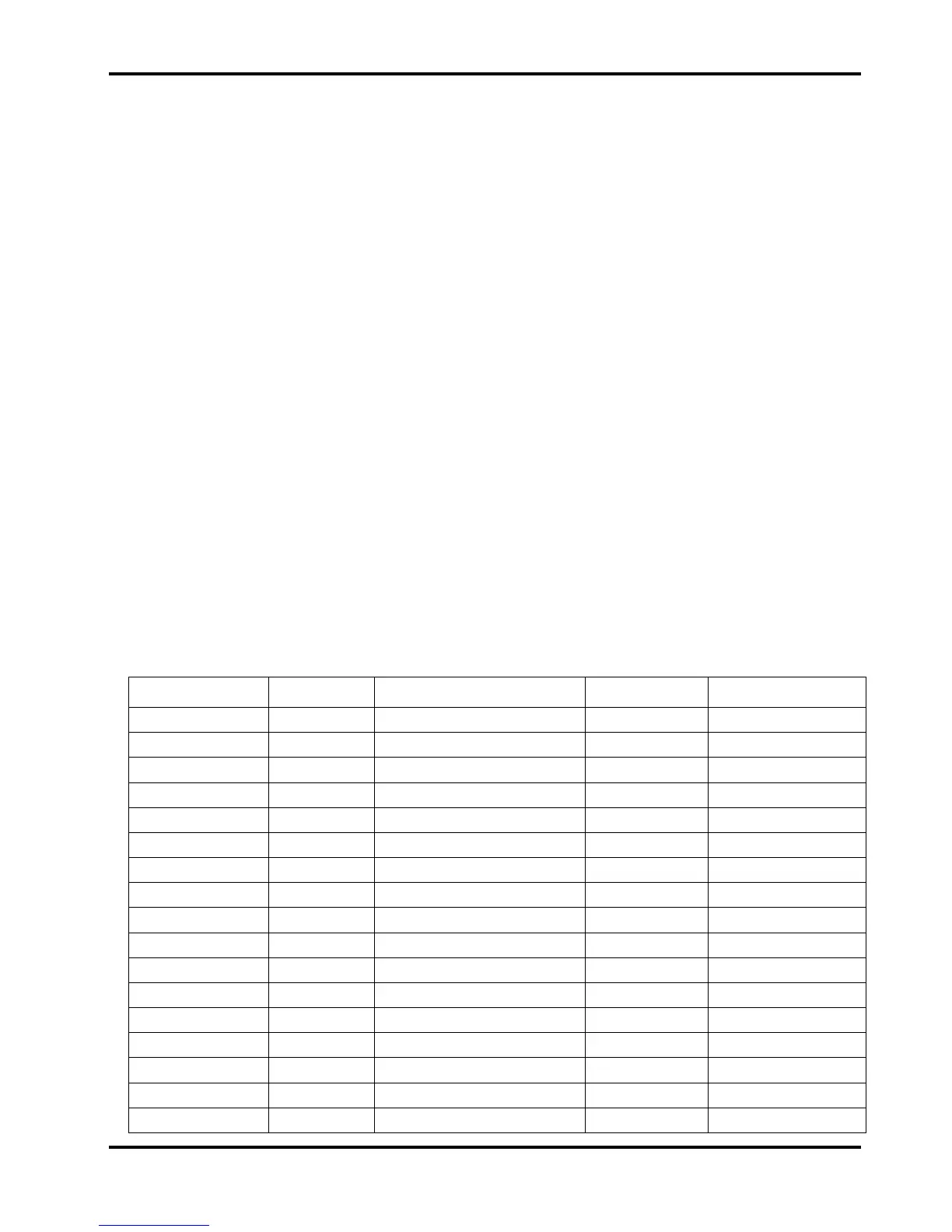

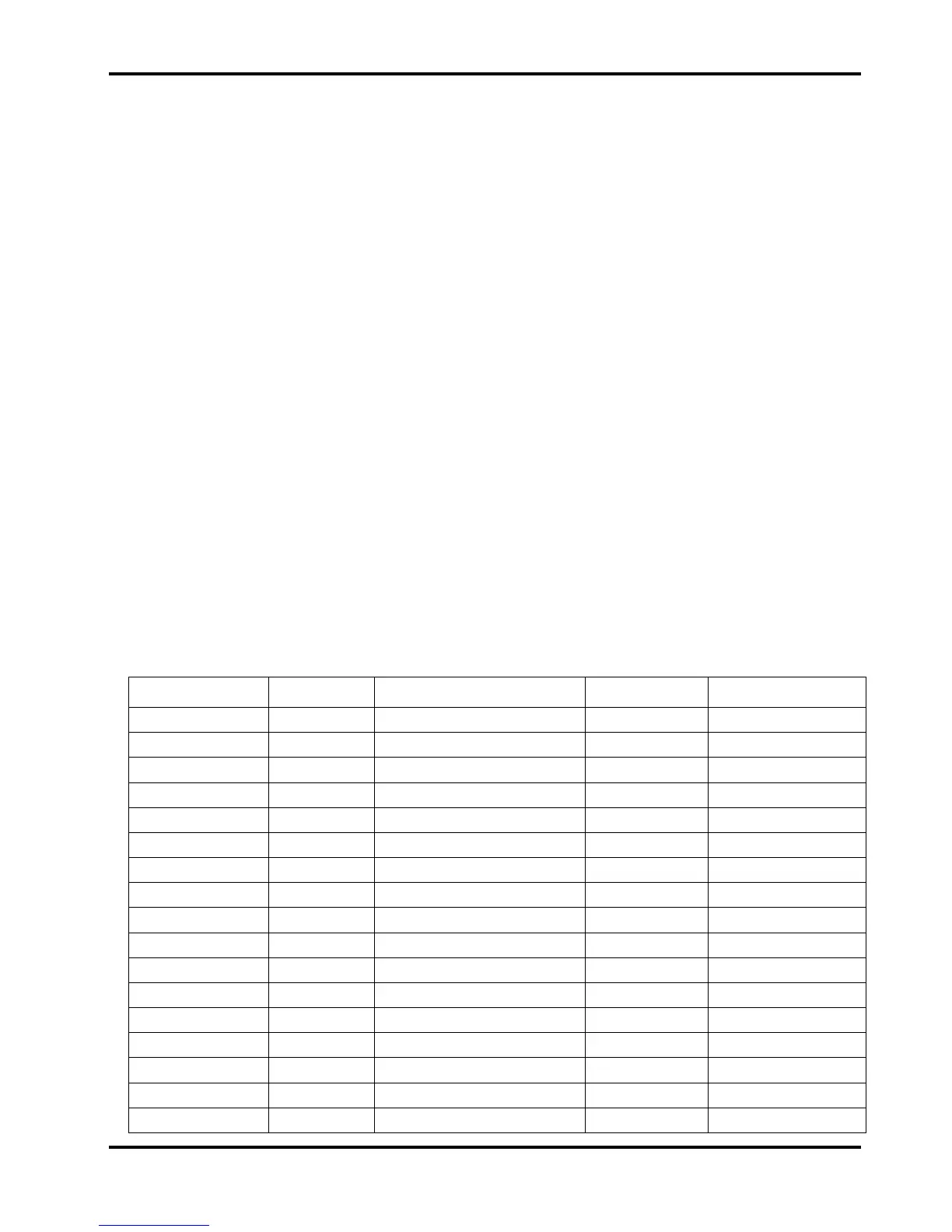

QL355

Step/Range Settings Adjust for:- Load Detail

1, 35V 3A 0.01V 3A 10mV ± 0.5mV DVM o/p 0V

2, 35V 3A 0.01V 3A 0.010V on display DVM V readback zero

3, 35V 3A 35V 3A 35V ± 0.5mV DVM o/p V span

4, 35V 3A 35V 3A 35.000 on display DVM V readback span

5, 35V 3A 0.01V 3A 10mV ± 0.5mV DVM o/p 0V

6, 35V 3A 35V 3A 35V ± 0.5mV DVM o/p V span

7, 35V 3A 2V 0.001A 1mA ± 0.5mA milli-ammeter o/p A offset

8, 35V 3A 2V 0.001A 0.001 on display milli-ammeter A readback zero

9, 35V 500mA 2V 0.1mA 0.1mA ± 0.05mA milli-ammeter o/p mA offset

10, 35V 500mA 2V 0.1mA flashing 0.0/0.1 on display milli-ammeter mA readback zero

change load

11, 15V 5A 2V 4A 4A ± 0.5mA ammeter o/p A span

12, 15V 5A 2V 4A 4.000 on display ammeter A readback span

13, 15V 5A 2V 4.1A 4.100 on display ammeter A readback 13bit

14, 35V 500mA 2V 400mA 400mA ± 0.05mA ammeter o/p mA span

15, 35V 500mA 2V 400mA 400.0 on display ammeter mA readback span

16, 35V 500mA 2V 410mA 410.0 on display ammeter mA readback 13bit

11

Loading...

Loading...