9

03

Installation

Operator’s Manual 2010 Rev B p/n 2010

MOUNTING STRESS

Stress imparted from incorrectly aligned piping

or mounting will create problems with bearing

and seal life, possibly leading to premature

internal contact. The blower should sit stress-

free and evenly on its supporting surface. Take

care to evenly tighten the mounting bolts to avoid

imparting undue stress into the blower. Stress

can be checked in a free state with feeler stock or

veried on a previously installed blower with the

aid of a dial indicator. Spring or gap should be less

than 0.002 in. (0.05 mm).

BLOWER AIR INTAKE

To minimize maintenance, supply the blower with

the cleanest air possible. The air must not contain

any ammable or toxic gases, as the blower will

concentrate these gases. This could result in

damage to the blower and surrounding property

and lead to personal injury or death.

WARNING

!

Do not use air blowers on explosive or

hazardous gases. Each size blower has limits

on pressure differential, running speed, and

discharge temperature. These limits must not

be exceeded.

If it is necessary to take air from a remote source,

such as in a vacuum application, make sure the

diameter of the piping is at least the equal to the

diameter of the blower inlet. For distances greater

than 20 ft (6 m), enlarge the pipe diameter to

reduce inlet restriction. Excessive restriction will

reduce the efciency of the blower and elevate its

discharge temperature.

The piping used should also be corrosion-resistant

and free of scale and dirt. Keep the inlet covered to

keep out foreign objects and rain.

MOTOR DRIVES

Two drive connections commonly used are direct

drive and V-belt drive.

DIRECT COUPLED

When installing the motor directly to the blower,

align the shafts to the coupling according to the

coupling manufacturer’s instructions.

Blowers shipped with motor directly coupled and

mounted on a common base have been aligned

prior to shipment. Further alignment is not normally

necessary, but be sure to check the alignment and

make adjustments if necessary prior to starting the

blower.

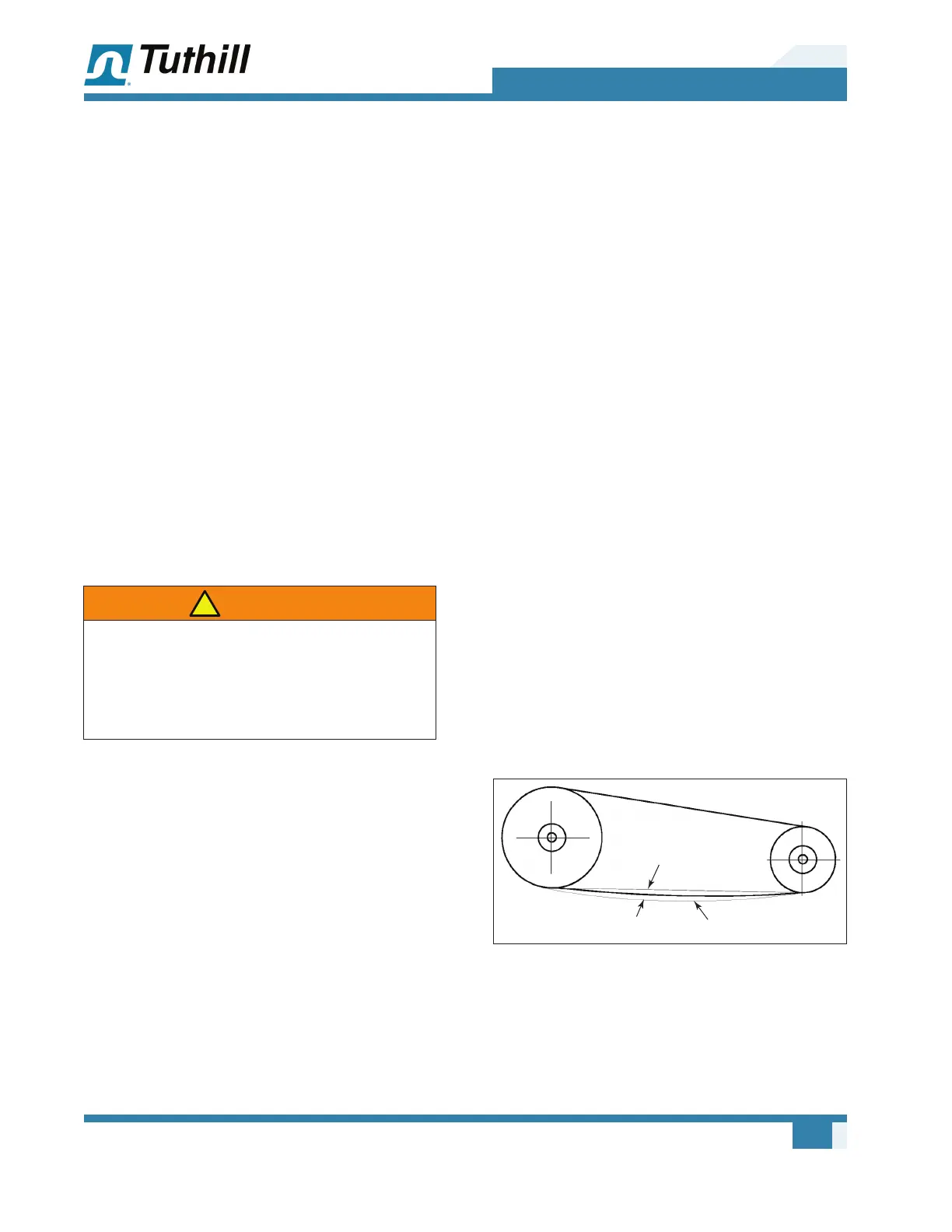

V-BELTS

If the motor and blower are V-belt connected, the

sheaves on both the motor and blower shafts

should be as close to the shaft bearings as

possible. Blower sheave is not more than 1/4 in.

(6.5 mm) from the blower drive end cover. The

drive sheave is as close to the driver bearing as

possible. Take care when installing sheaves on

the blower and motor shafts. Make sure the face is

accurately in line to minimize belt wear.

Adjust the belt tension to the manufacturer’s

specications using a belt tension tester. Check

new belts for proper tension after 24 hours of run

time. When manufacturer data is not available,

industry guidelines recommend 1/64 in. deection

for each inch of span (0.157 mm deection per

centimeter of span) at 8 to 10 lb (3.6 – 4.5 kg) of

force in the center of the belt. See Figure 3-3.

Too Tight

Slight Bow

Too Loose

20/64” = 5/16” (8 mm)

20”

(50.8 cm)

8-10 lbs.

(3.6-4.5 kg)

Figure 3-3 – General appearance of V-belt drive

Loading...

Loading...