Operator’s Manual 1808 022016 ENG

10

05

Installation

DIRECT DRIVE

ounted the pump on a fl at and level surface. f

the pump is to be installed outdoors, ensure the

motor, painting, peripheral equipment, parts, etc.,

are suitable for outdoor operation. Allow enough

space around the pump for safe maintenance

work and periodic inspections. This includes, at

a minimum, the ability to access oil fi ll and drain

locations and to vi ew the oil leve l sight glass.

The K D series Drive -Drive models are direct drive n

by two methods

• 8 pole (K D5 0) or 12 pole (K D30) motors

• ear reducer driven by or pole motor

f the pump was purchased directly from Tuthill,

the coupling has been factory-aligned and tested.

When installing the pump alone to be direct-

coupled to a motor or gear drive , ensure the

coupling alignment meets the manufacturer’s

recommendations to avoid ecessive loading of the

pump or motor bearings.

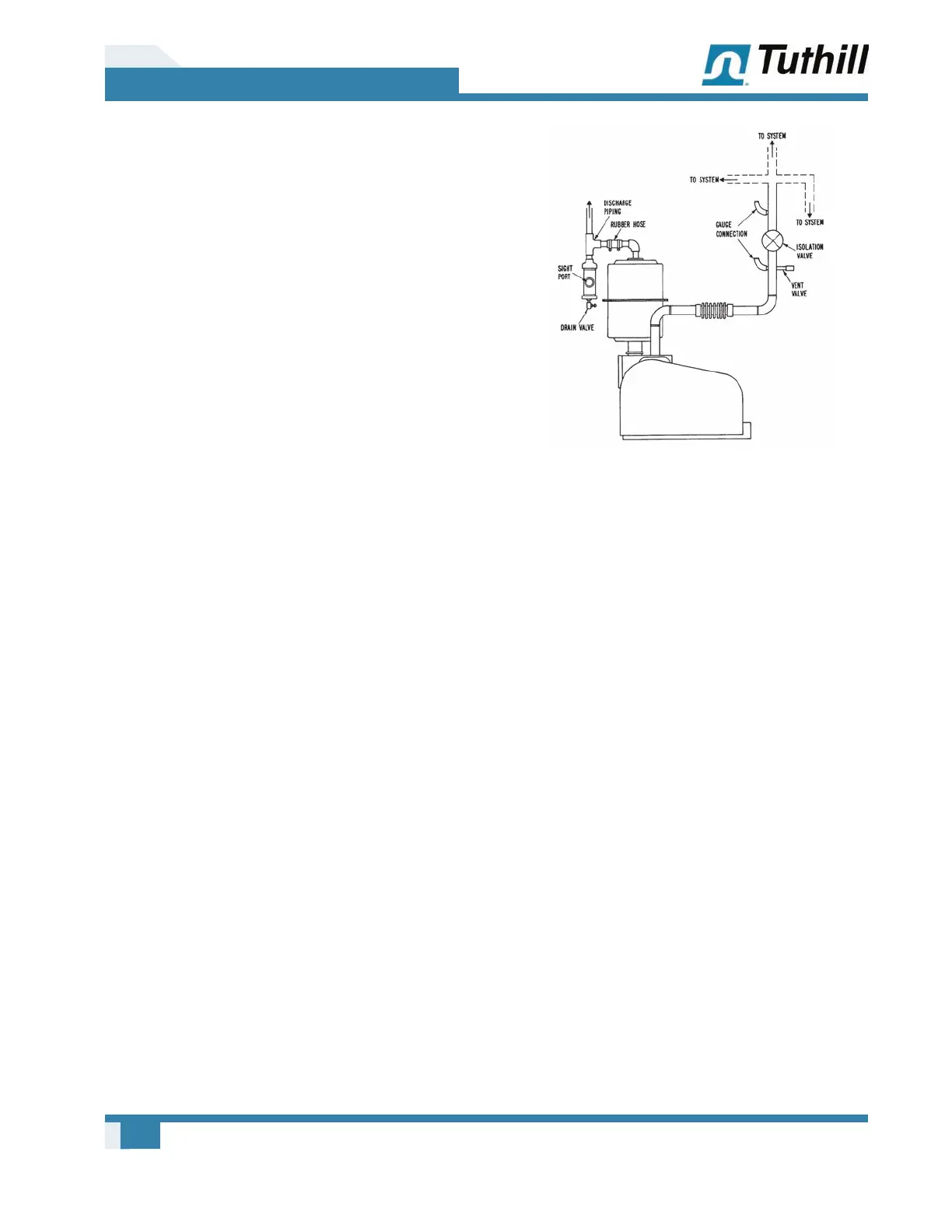

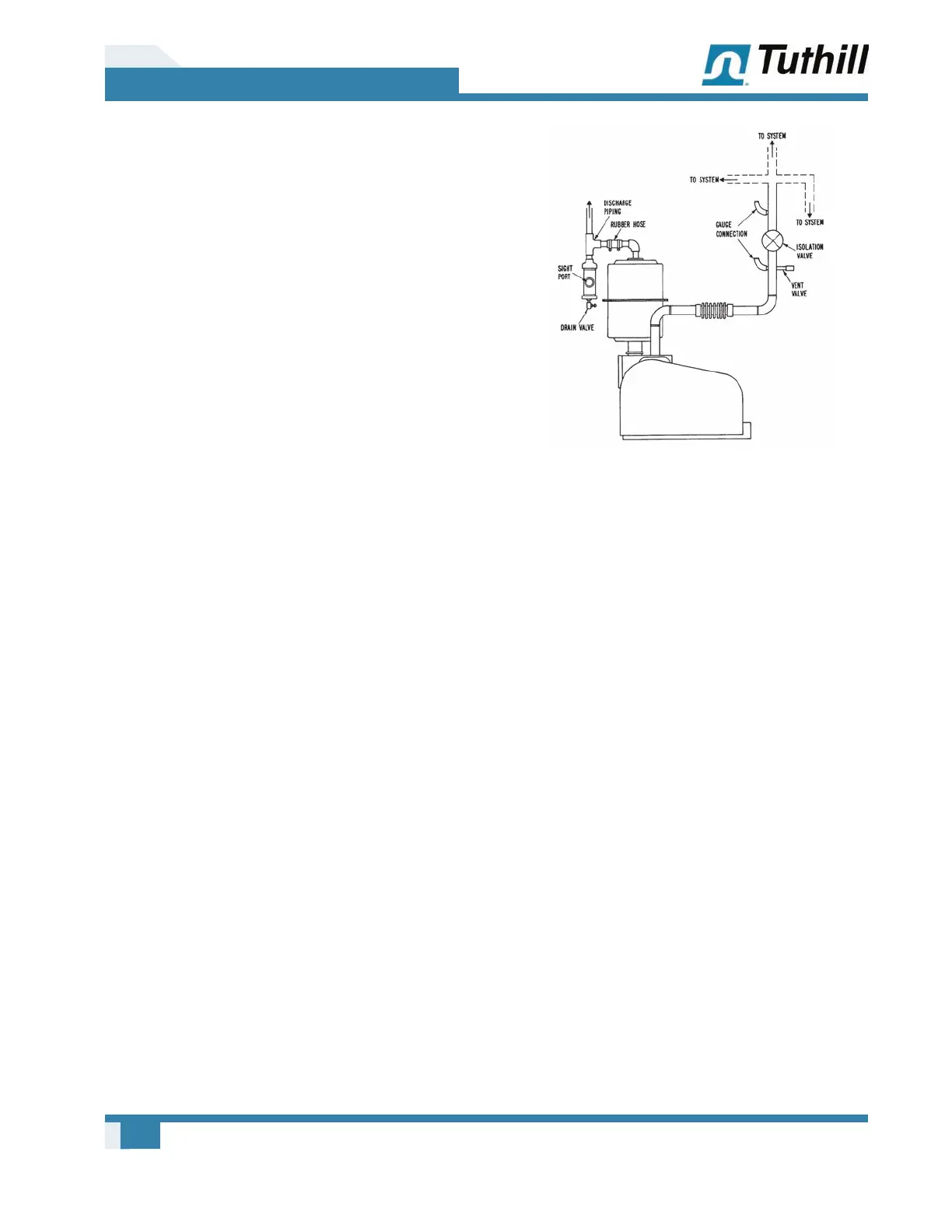

DISCHARGE PIPING

t may be desirable to connect discharge piping

from the oil separator to the outside to dispose

of ehaust gases and vapors. See Figure 5 -2 on

page 10 . When connecting discharge piping,

place a dropout trap adacent to the oil separator

to trap the condensate, which would otherwise

drain back into the oil. If the condensate is water,

drain it as necessary to prevent it from fl owing

back into the reservoir. A fl eible connector, such

as a rubber hose, at the discharge of the pump

is necessary to make the piping fl eible and to

provi de a conve nient disconnect point for servi cing.

Turned down the outside end of the discharge line

to prevent entry of precipitation.

Figure 5-2 – Typical Manifold Arrangement

INLET PIPING

Size and design the inlet piping with three

obectives in mind

• To prevent undue gas fl ow restriction

• To prevent pump fl uids from splashing into the

process chamber

• To protect the pump from inection of particulate

matter

Tuthill recommends that the va cuum piping to the

pump inlet be as large in diameter and as short

in length as possible and no smaller in diameter

than the pump inlet. See Figure 5 -2 on page

10 for recommended arrangement of va cuum

manifolding.

As with all rotary mechanical pumps, it is

necessary to install a fl eible member in

the suction manifold of the pump to avo id

alignment problems and to reduce the possibility

of transmitting vi bration to and from other

components. elf-supporting, bellows-type, fl eible

connectors are recommended and are av ailable

from Tuthill V acuum & B lower. Use a connector be

fl eible enough to prevent vibration transmission

and yet rigid enough to prevent collapsing under

high va cuum.

Loading...

Loading...