21

09

Troubleshooting

Operator’s Manual 1808 022016 ENG

OIL CONTAMINATION

When the pressure has been satisfactory for

some time and then the pressure gradually

increases, this indicates oil contamination. When

this happens clean the oil by using gas ballast or

change the oil. Discolored oil does not necessarily

indicate contamination. onversely, vapors may

contaminate oil and not show any color change.

Oil drying can be checked by the crackling method

(few drops of oil on an aluminum household foil

heated by a match). If crackling does not occur, the

oil is dry to better than a few PPM of water.

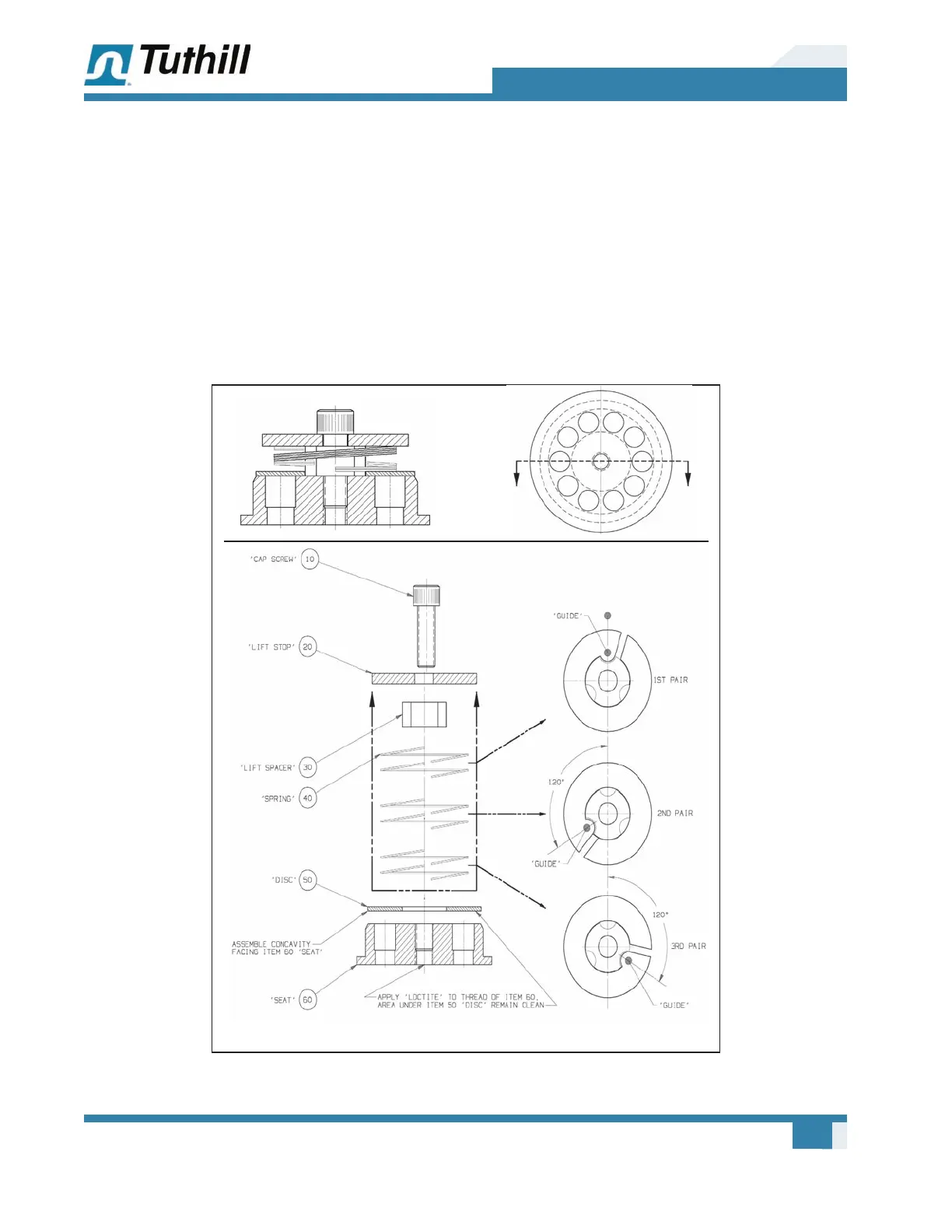

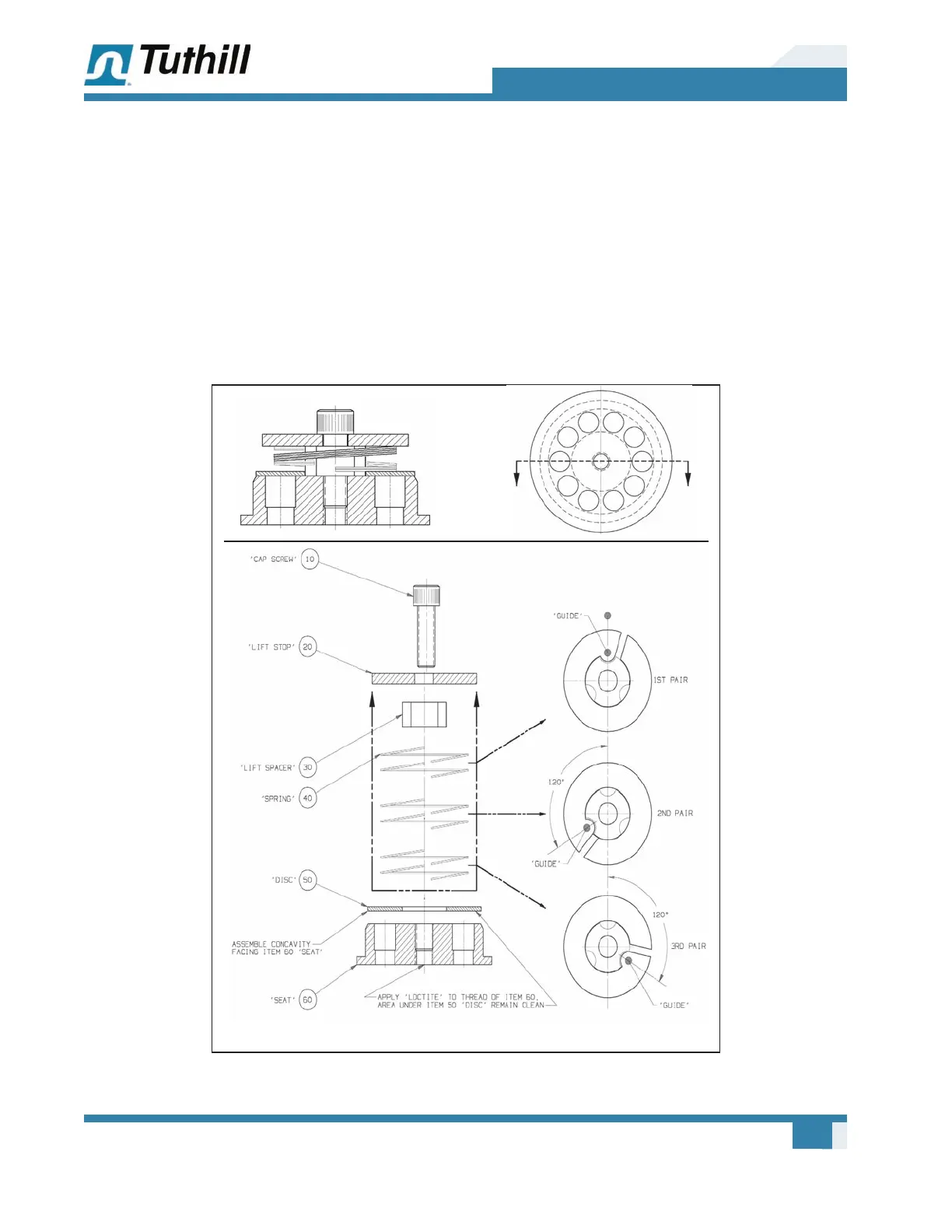

DISCHARGE VALVES

When the cause of poor pump performance is

not due to leaks or oil contamination, inspect

the discharge valves. The discharge valves (s ee

Figure 9 -1 on page 21) are located at the

exhaust ports and could malfunction due to foreign

matter preventing them from sealing or they may

be worn to the point that they no longer function

correctly.

ASSEMBLY

ASSEMBLY PROCEDURE

No individual component sales. Discharge valves are sold as an assembly only.

Figure 9-1 – Discharge Valve

Loading...

Loading...