Technical

Data

Approvals

The Model F822 thru F836 Mulsifyre

Nozzles are UL and ULC Listed, as

well as FM Approved.

The Model F822 thru F836 Mulsifyre

Nozzles with Model F880 Dust Caps

areULandULCListed.

Maximum Working Pressure

175 psi (12,1 bar).

Also refer to Figure 3, Note 2.

Discharge Coefficient

RefertoFigure1.

Water Distribution

Refer to Figure 2. Optimum flow pres-

sure is 30 to 60 psi (2,1 to 4,1 bar).

Thread Connection

3/4 inch NPT.

Physical Characteristics

(Basic Nozzle)

Body ..............Brass

Scroll ..............Brass

Physical Characteristics

(Nozzle with Dust Cap)

Body . . . . . Chrome Plated Brass

Scroll ..............Brass

DustCap........... EPDM

Wire..........StainlessSteel

Design

Criteria

Nozzle Placement. Where direct im-

pingement of water spray onto all of

the protected surface is required by

the Authority having Jurisdiction, the

nozzles are to be spaced and directed

so that their spray patterns will com-

pletely cover the plane-of-protection

with the minimum required average

density. With reference to Figure 2,

use of the “Design Spray Profile” for

the “Design Spray Area” will help as-

sure that direct impingement on all sur-

faces will occur. The “Design Spray

Area” shown at the top Figure 2 - Part

2 of 2 on Page 4 consists of the square

of length “S” within the circular “Overall

Spray Area”.

The maximum recommended axial

distances given in Figure 2 are based

on maintaining the specified spray pat-

terns under a maximum wind condition

of 15 MPH (24 km/h).

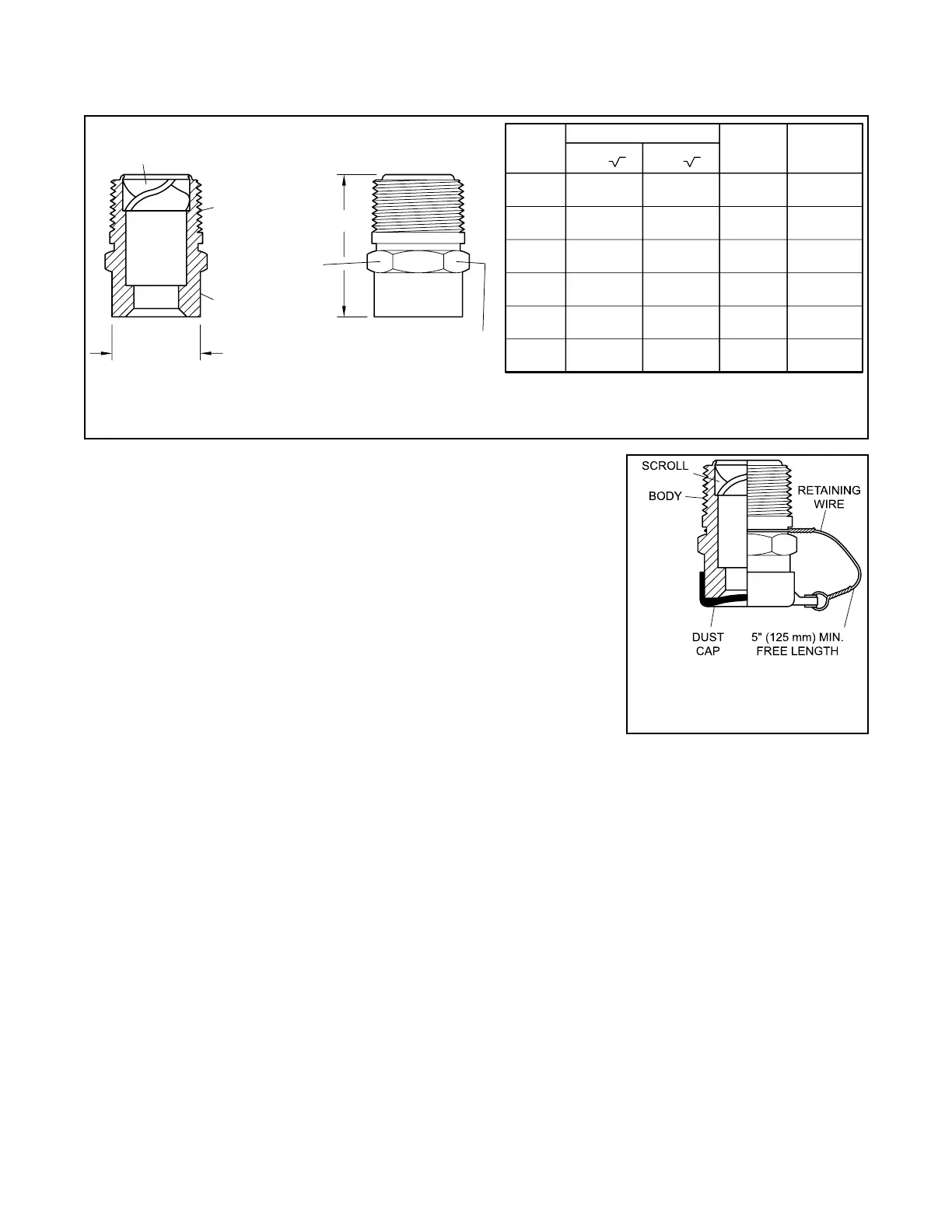

Dust Caps. The Model F880 Dust

Caps are rated for indoor and outdoor

use over a temperature range of -60F

to 150F (-51C to 65C). A minimum

residual (flowing) pressure of 15 psi

(1,0 bar) is required to assure release

of the Dust Cap.

Main Pipeline Strainers. Main pipe-

line strainers per NFPA 15 are re-

quired for systems utilizing Mulsifyre

Nozzles since their waterways are less

than 3/8 inch (9,5 mm) diameter. Indi-

vidual strainers are not required since

the openings in the scrolls will pass a

1/8 inch (3,2 mm) particle.

Page2of6

TFP810

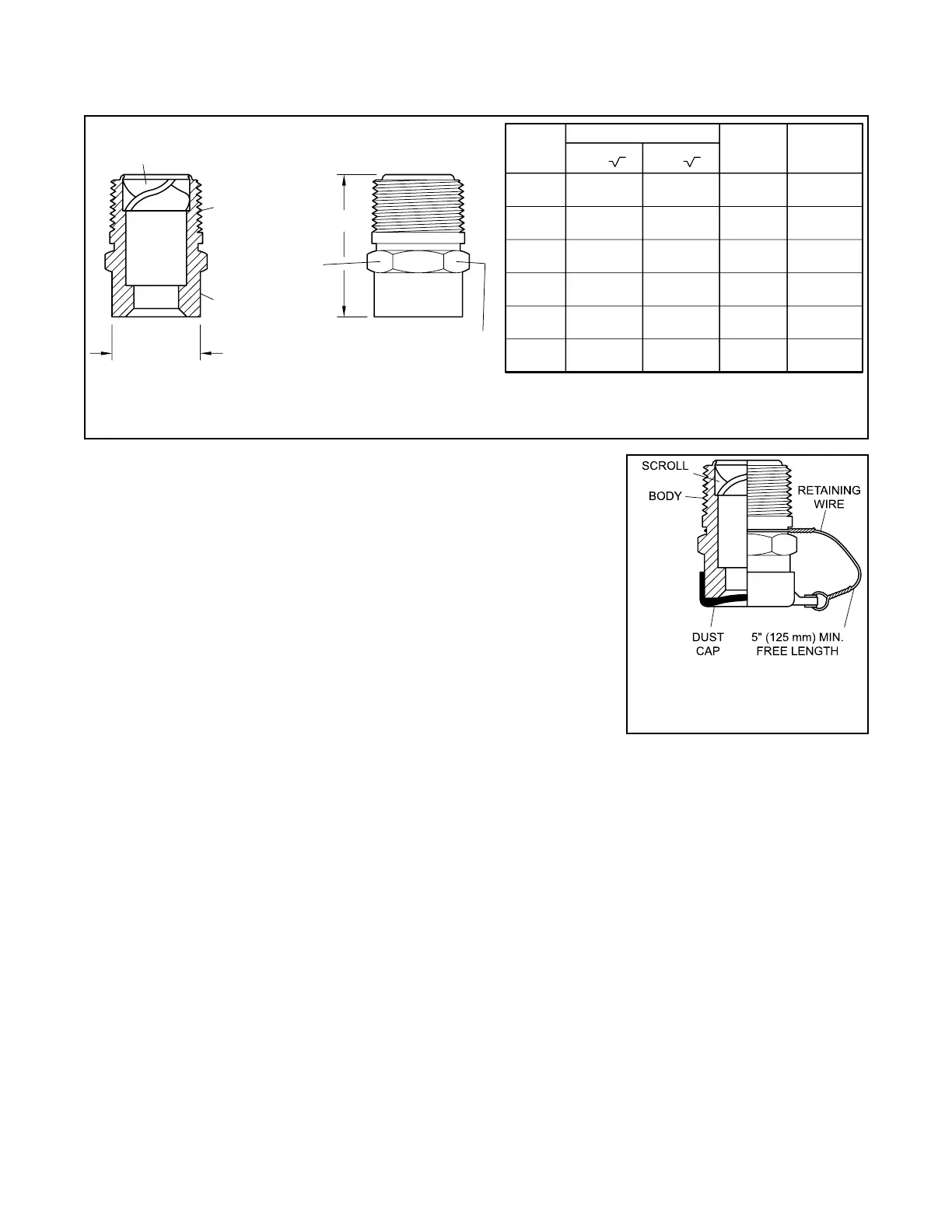

FIGURE 1

MODEL F822 THRU F834 MULSIFYRE NOZZLES

NOMINAL DIMENSIONS

"L"

1" DIA.

(25,4 mm)

(PASSES A 1/8"

PARTICLE)

SCROLL

BODY

3/4"

NPT

F822

F824

F826

F828

F832

F834

NUMBER

MODEL

CODE

"L"

2-3/4"

(70 mm)

GRAY

ALUMINUM

1-5/8"

1-13/16"

(47 mm)

1-11/16"

(43 mm)

(42 mm)

1-5/8"

1-5/8"

(42 mm)

(42 mm)

WHITE

ORANGE

RED

YELLOW

LENGTH

NOMINAL

COLOR

(27 mm)

WRENCH

ACROSS

1-1/16"

FLATS

COLOR CODE PAINTED

ON WRENCH FLATS

K-FACTOR

(GPM ÷ psi)

NFPA

ISO/SI

(LPM ÷ bar)

2.0

2.3

2.7

2.6

4.6

5.1

73,4

37,4

66,2

38,9

28,8

33,1

FIGURE 2

MULSIFYRE NOZZLES

WITH DUST CAPS

Loading...

Loading...