Installation

Mulsifyre Nozzles must be installed in

accordance with the following instruc-

tions:

NOTE

A leak tight 3/4 inch NPT nozzle joint

should be obtained with a torque of 10

to 20 ft.lbs. (13,4 to 26,8 Nm). A maxi-

mum of 30 ft.lbs. (40,7 Nm) of torque

is to be used to install nozzles with 3/4

NPT connections. Higher levels of

torque may distort the nozzle inlet and

cause leakage or impairment of the

nozzle.

Step 1. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the nozzle into the nozzle fitting.

Step 2. Tighten the nozzle into the

nozzle fitting using an adjustable cres-

cent wrench. With reference to Figure

1 the adjustable crescent wrench is to

be applied to the wrench flats.

REPLACEMENT DUST CAPS

When replacement Dust Caps are in-

stalled, there is to be a minimum of 5

inches (125 mm) of Wire (Ref. Figure

2) between where the Wire is looped

around the nozzle thread relief and

attached to the Dust Cap. The mini-

mum length of 5 inches (125 mm) will

help to assure that there will be an

unrestricted flow from the nozzle outlet

during operation.

Care and

Maintenance

The Mulsifyre Nozzles must be main-

tained and serviced in accordance

with the following instructions:

NOTE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down

the affected fire protection system

must be obtained from the proper

authorities and all personnel who may

be affected by this action must be no-

tified.

Mulsifyre Nozzles must never be

painted, plated, coated or altered in

any way after leaving the factory; oth-

erwise, the spray performance may be

impaired.

Care must be exercised to avoid dam-

age to the nozzles - before, during,

and after installation. Nozzles dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed.

Frequent visual inspections are rec-

Page4of6

TFP810

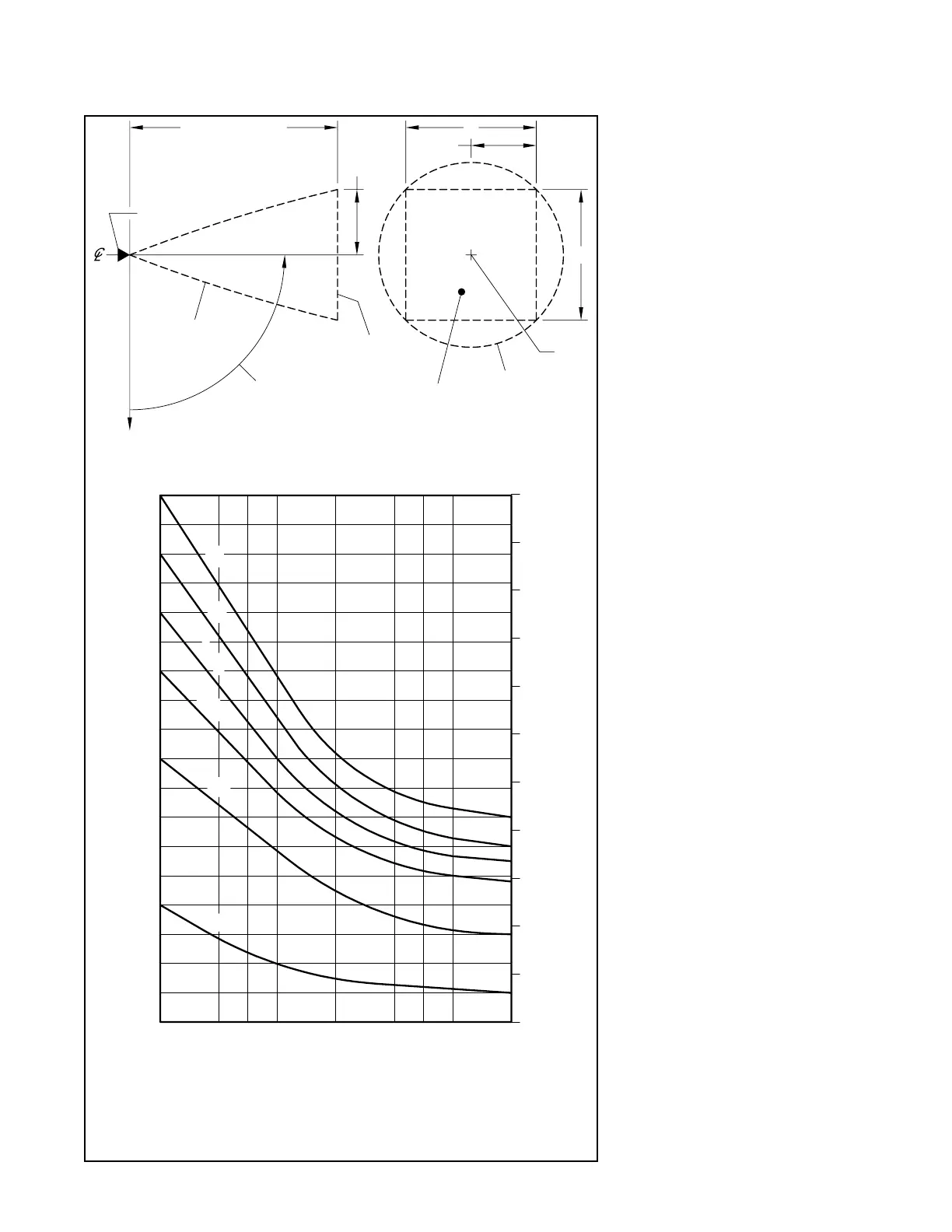

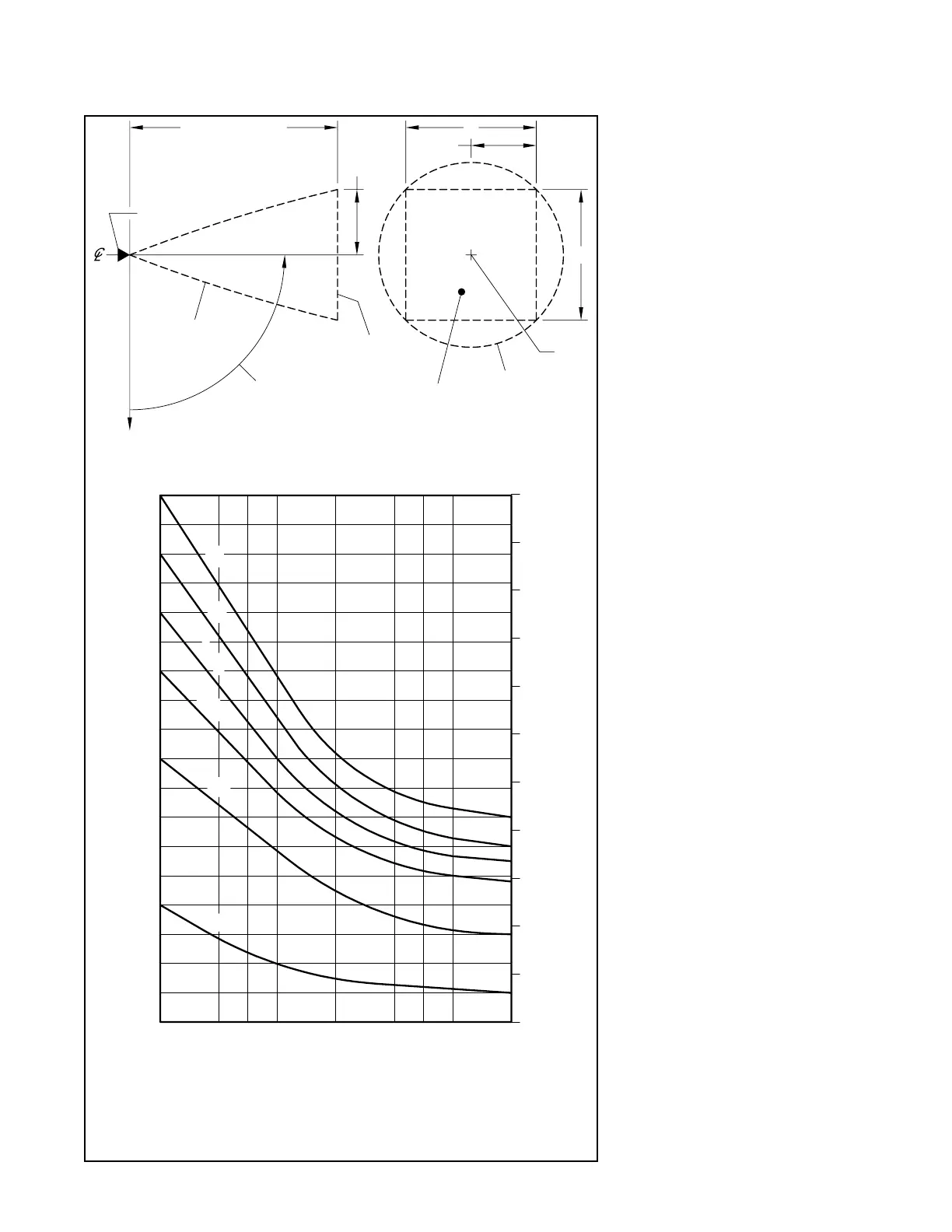

FIGURE 3 — PART 2 of 2

WATER DISTRIBUTION DESIGN DATA

AXIAL DISTANCE S

S/2

S/2

S

NOZZLE

AXIS

OVERALL

SPRAY

AREA

DESIGN

AREA

SPRAY

PLANE OF

PROTECTION

PROFILE

SPRAY

DESIGN

(90° SHOWN)

ANGLE

ORIENTATION

0° (GRAVITY)

5,0

4,0

3,0

2,0

1,0

0

0°

6

16

18

14

12

10

8

4

2

0

30° 45° 60° 90° 120° 135° 150° 180°

11

1

3

5

7

9

13

15

17

0,5

1,5

2,5

3,5

4,5

5,5

(GRAVITY)

ORIENTATION ANGLE

F826

F824

F822

F834

F828

F832

TO PLANE OF PROTECTION, FEET

MAXIMUM RECOMMENDED AXIAL DISTANCE

TO PLANE OF PROTECTION, METERS

MAXIMUM RECOMMENDED AXIAL DISTANCE

Loading...

Loading...