mum of 21 ft.lbs. (28,5 Nm) of torque

is to be used to install sprinklers.

Higher levels of torque may distort the

sprinkler inlet with consequent leak-

age or impairment of the sprinkler.

Do not attempt to compensate for in-

sufficient adjustment in an Escutcheon

Plate by under- or over-tightening the

Sprinkler. Readjust the position of the

sprinkler fitting to suit.

Step 1. The sprinkler must only be

installed in the pendent position and

with the centerline of the sprinkler per-

pendicular to the mounting surface.

Step 2. Remove the Protective Cap.

Step 3. With pipe thread sealant ap-

plied to the pipe threads, and using

the W-Type 18 Wrench shown in Fig-

ure 2, install and tighten the Sprink-

ler/Support Cup Assembly into the fit-

ting. The W-Type 18 Wrench will

accept a 1/2 inch ratchet drive.

TFP440

Page 3 of 4

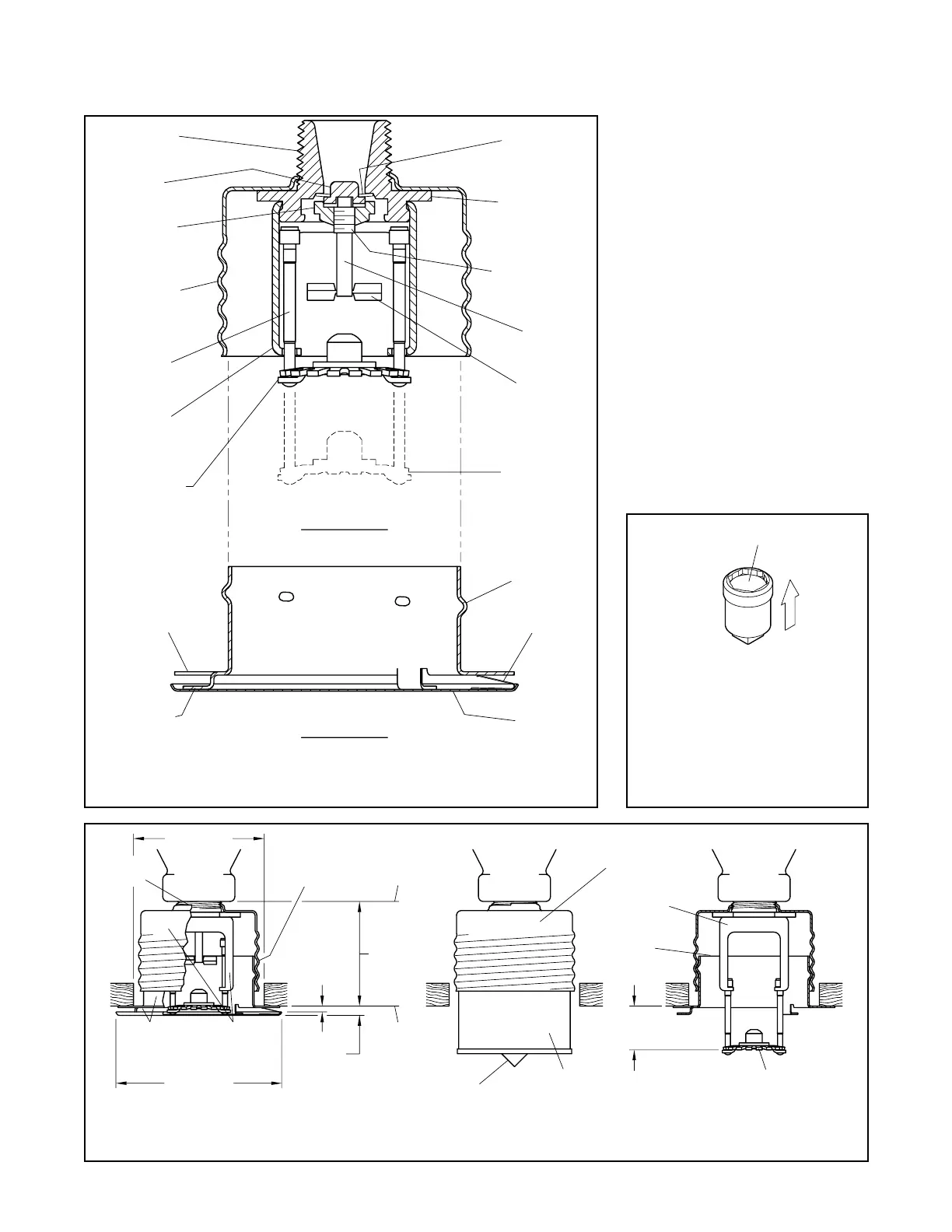

FIGURE 1

SERIES LFII (TY2596) RESIDENTIAL

CONCEALED PENDENT SPRINKLER

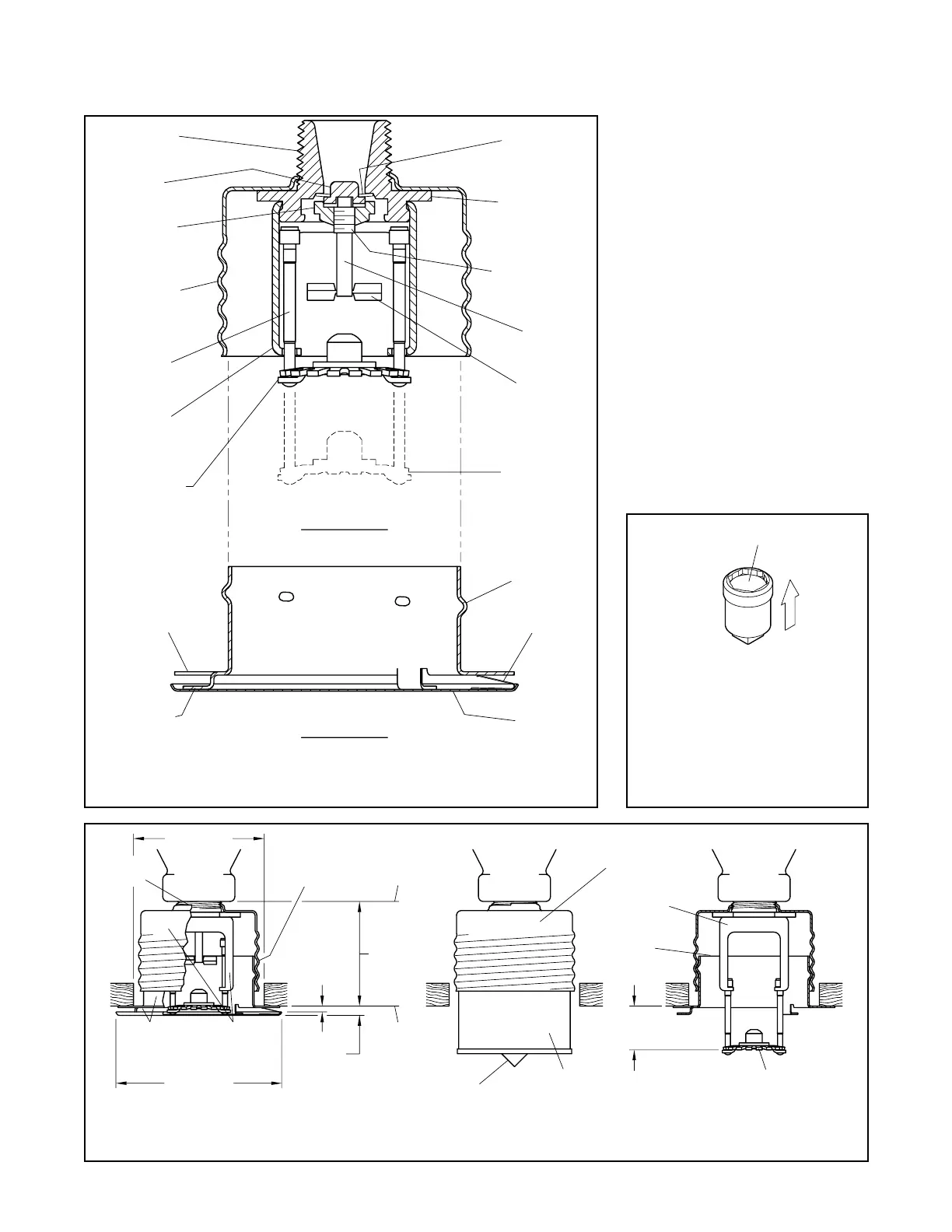

FIGURE 3

SERIES LFII (TY2596) RESIDENTIAL CONCEALED PENDENT SPRINKLER

INSTALLATION DIMENSIONS / PROTECTIVE CAP / ACTIVATED DEFLECTOR

FIGURE 2

W-TYPE 18

SPRINKLER WRENCH

(81,0 mm)

3-3/16" DIA.

1/2"

NPT

(63,5 mm)

2-1

2" DIA.

MOUNTING

SURFACE

(4,8 mm)

3/16"

1/8" GAP

(3,2 mm)

FITTING

SPRINKLER

FACE OF

1/2" (12,7 mm)

1" (25,4 mm)

TIP OPERATED POSITION

DEFLECTOR IN

1/2" (12,7 mm)

ADJUSTMENT

THREADED

SPRINKLER-

SUPPORT CUP

ASSEMBLY

OPERATED

SPRINKLER

1-15/16"±1/4"

±6,4 mm)

(49,2 mm

SPRINKLER-

SUPPORT CUP

ASSEMBLYASSEMBLY

COVER-

RETAINER

COVER

PLATE

RETAINER

DISPOSABLE

PROTECTIVE CAP

PLATE

COVER

EJECTION

SPRING

DIMPLES

WITH THREAD

RETAINER

ASSEMBLY

SEALING

COMPRESSION

SCREW

POSITION)

(OPERATED

DEFLECTOR

FLUSH WITH

SURFACE IS

SUPPORT CUP

UNTIL MOUNTING

THREAD INTO

SOLDER

TAB

CEILING

DEFLECTOR

CAP

COVER PLATE/RETAINER

ASSEMBLY

SPRINKLER/SUPPORT CUP

ASSEMBLY

(1/2" NPT)

BODY

AREA

WRENCHING

SPRINKLER

SADDLE

ROLL FORMED

THREADS

CUP WITH

SUPPORT

ELEMENT

SOLDER LINK

LEVER

GUIDE

PIN

HOUSING

GUIDE PIN

RECESS

WREN

H

WITH SPRINKLER

ENGAGEMENT

IN TO ENSURE

WREN

HIN

AREA

PUSH WRENCH

Loading...

Loading...