TFP230

Page 4 of 6

Design

Criteria

The TYCO Model SW-20 and SW-24,

11.2 K-factor, Extended Coverage Ordi-

nary Hazard (ECOH) Horizontal Sidewall

Sprinklers are for use in ordinary haz-

ard occupancies with non-combustible

un obstructed construction and with a

ceiling slope not exceeding 2 inches

per foot (9.2°), using the design crite-

ria provided in Table A, (as well as any

additional requirements specied in

NFPA 13 for Extended Coverage Side-

wall Spray Sprinklers).

A 36 inch (914 mm) clearance must

be maintained between the top of the

sprinkler deector and any miscella-

neous storage.

The SW-20 and SW-24 may be in stalled

on sloped ceilings in loading docks with

a maximum roof slope of 4 inches per

foot (18.4°) as shown in Figure 4 and

using the design criteria provided in

Table A.

The SW-20 and SW-24 can be used only

for exposed applications. The SW-20

and SW-24 cannot be recessed.

Installation

The TYCO Model SW-20 and SW-24,

11.2 K-factor, Extended Coverage Ordi-

nary Hazard (ECOH) Horizontal Sidewall

Sprinklers must be installed in accor-

dance with this section.

General Instructions

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 in. (1,6

mm).

A leak tight 1/2 inch NPT sprinkler joint

should be obtained with a minimum

to maximum torque of 7 to 14 ft.-lbs.

(9,5 to 19,0 Nm). Higher levels of torque

can distort the sprinkler Inlet with con-

sequent leakage or impairment of the

sprinkler.

Do not attempt to compensate for in-

sufcient adjustment in the Sprinkler by

under- or over-tightening the Sprinkler/

Support Cup Assembly. Re-adjust the

position of the sprinkler tting to suit.

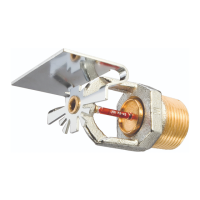

Step 1. Horizontal sidewall sprinklers

are to be installed with their center-

line perpendicular to the back wall and

parallel to the ceiling. The word “TOP”

on the deector is to face towards the

ceiling.

Step 2. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler tting.

Step 3. Tighten the sprinkler into the

sprinkler tting using only the W-Type

3 (End B) Sprinkler Wrench (Ref. Fig-

ure 3). With reference to Figures 1 and

2, the W-Type 3 Sprinkler Wrench is to

be applied to the sprinkler wrench ats

Care and

Maintenance

The TYCO Model SW-20 and SW-24,

11.2 K-factor, Extended Coverage Ordi-

nary Hazard (ECOH) Horizontal Sidewall

Sprinklers must be maintained and ser-

viced in accordance with this section.

Before closing a re protection system

main control valve for maintenance work

on the re protection system that it con-

trols, obtain permission to shut down the

affected re protection system from the

proper authorities and notify all person-

nel who may be affected by this action.

The owner is responsible for the in-

spection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards

of the National Fire Protection Associa-

tion (e.g., NFPA 25), in addition to the

standards of any other authorities hav-

ing jurisdiction. Contact the installing

contractor or sprinkler manufacturer re-

garding any questions.

Automatic sprinkler systems should be

inspected, tested, and maintained by a

qualied Inspection Service in accor-

dance with local requirements and/or

national code.

Absence of an escutcheon, which is

used to cover a clearance hole, may

delay the time to sprinkler operation in

a re situation.

Automatic sprinklers must never be

painted, plated, coated or otherwise

altered after leaving the factory. Modi-

ed sprinklers must be replaced. Sprin-

klers that have been exposed to corro-

sive products of combustion, but have

not operated, should be replaced if they

cannot be completely cleaned by wiping

the sprinkler with a cloth or by brushing

it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers before, during, and

after installation. Sprinklers damaged

by dropping, striking, wrench twist/

slippage, or the like, must be replaced.

Also, replace any sprinkler that has a

cracked bulb or that has lost liquid from

its bulb. (Ref. Installation Section).

Frequent visual inspections are recom-

mended to be initially performed for

corrosion resistant coated sprinklers,

after the installation has been complet-

ed, to verify the integrity of the corro-

sion resistant coating. Thereafter, an-

nual inspections per NFPA 25 should

sufce; however, instead of in specting

from the oor level, a random sampling

of close-up visual inspections should

be made, so as to better determine the

exact sprinkler condi tion and the long

term integrity of the corrosion resistant

coating as it may be affected by the cor-

rosive conditions present.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-re.com.

Loading...

Loading...