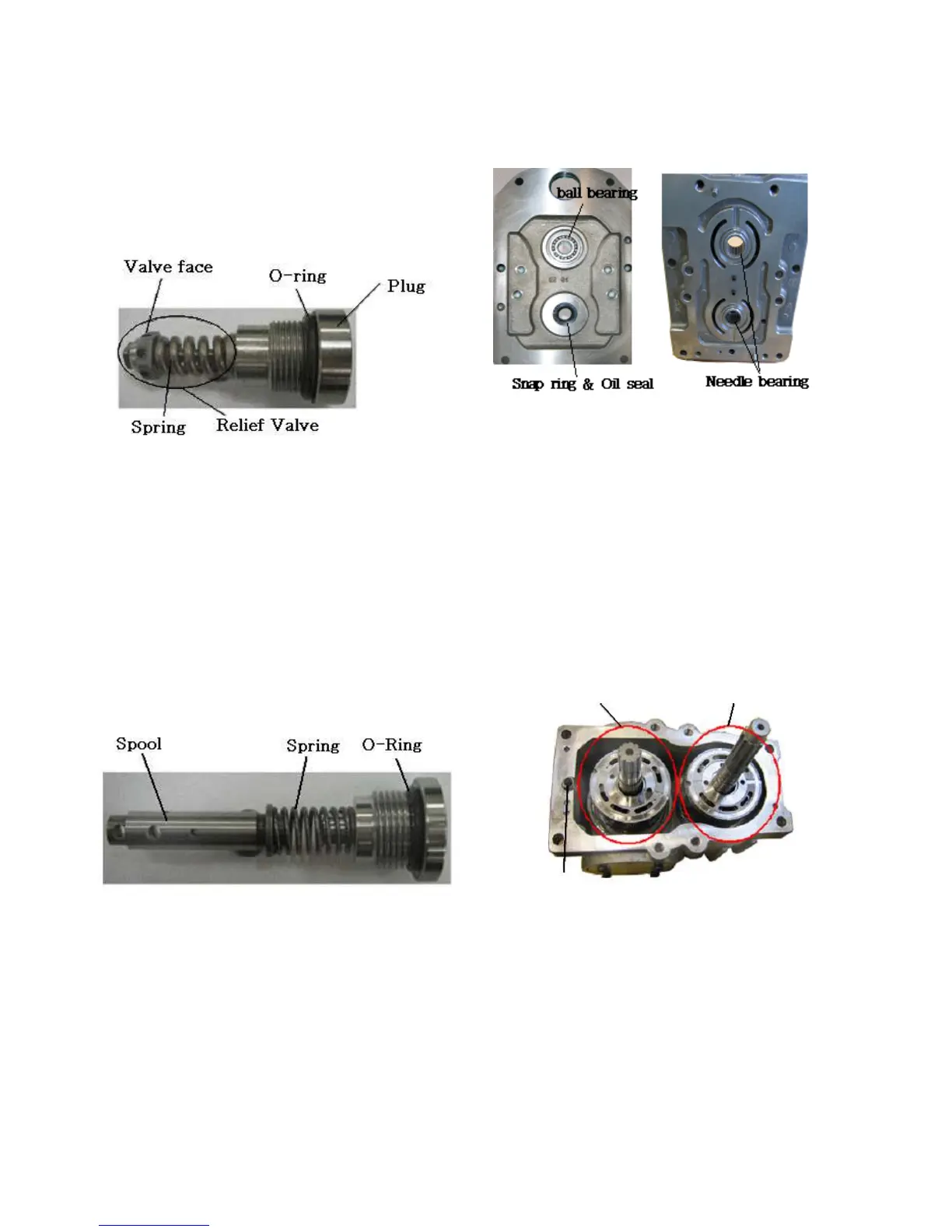

9. Examine the relief valve faces, and the seats in

the body. The faces of the relief valve and the seats

in the body should be free of burns and defects.

10. Remove two neutral valves from body. Clean the

valves in a suitable solvent and check for damage or

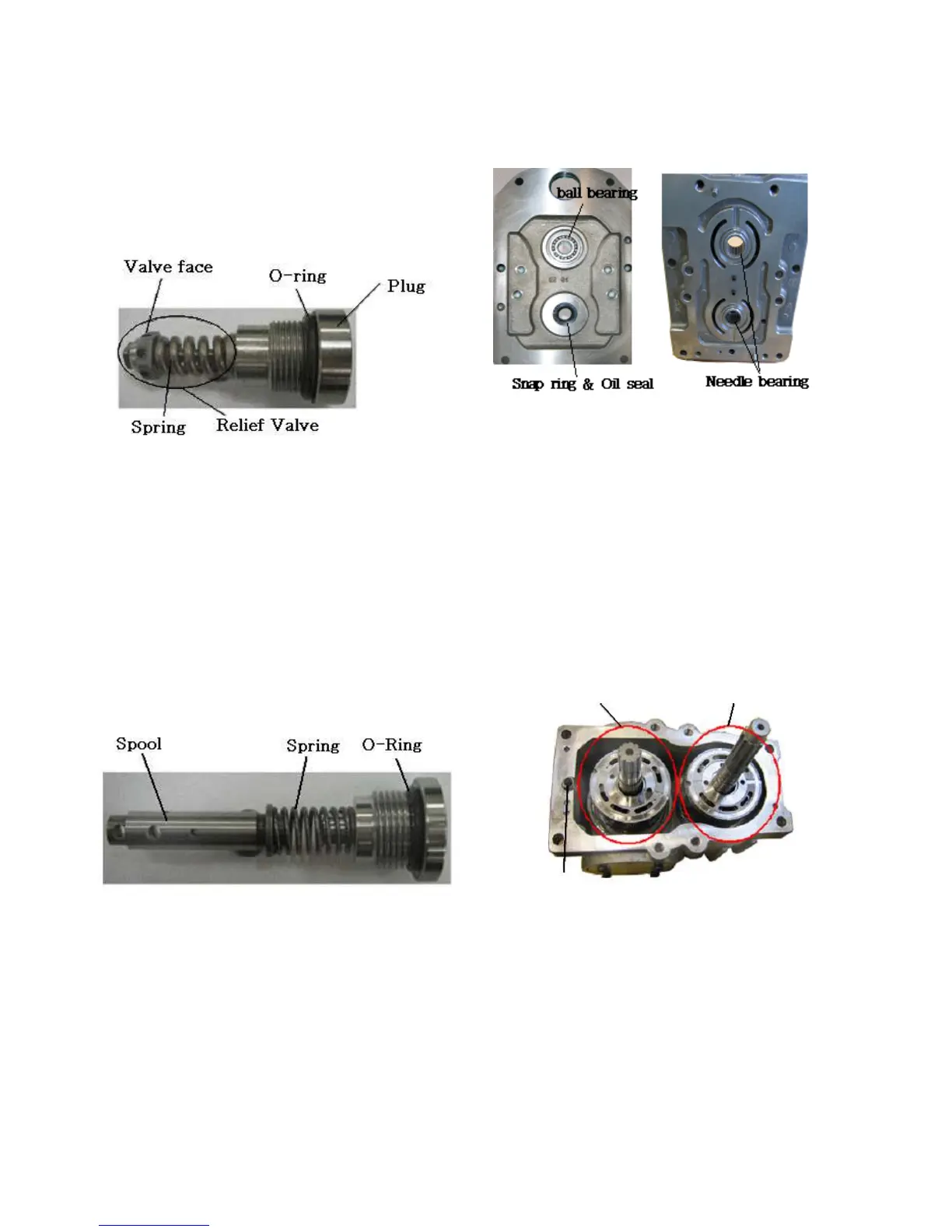

12. Inspect ball bearing. The bearing should spin

freely.If replacement is necessary, press bearing out

from the outer side of body.

13. Inspect oil seal. If replacement is necessary,

replace it.

IMPORTANT : To avoid damage to bearings ,

when removing or installing, press only against

side of bearing with lettering.

When removing bearings from body, be extremely

careful not to damage machined surfaces

Note : The relief valve is dual purpose valve. The

valve contains two springs. A weak spring in the

plug(check valve when other circuit is in use) and a

strong spring (34MPa relief valve). The relief valve

can not be adjusted, and there is no serviceable part

inside. If any malfunction is suspected, replace the

relief valve.

4-22

in spool Two neutral valves are interchangeable, but

it is recommended that the valves go into original

holes during assembly.

Housing Disassembly

IMPORTANT:

The HST housing is aluminum material and can be

easily damaged by steel tools. Be careful not to

damage machined surfaces. Do not use screw driver

or other sharp objects.

11. Inspect needle bearings. The bearing should spin

freely and needles should not fall out of bearing

cage. If replacement is necessary, press bearing

out from the outer side of body.

Pump part Motor part

Spring for charge relief valve

Loading...

Loading...