6

Page.

/ 8

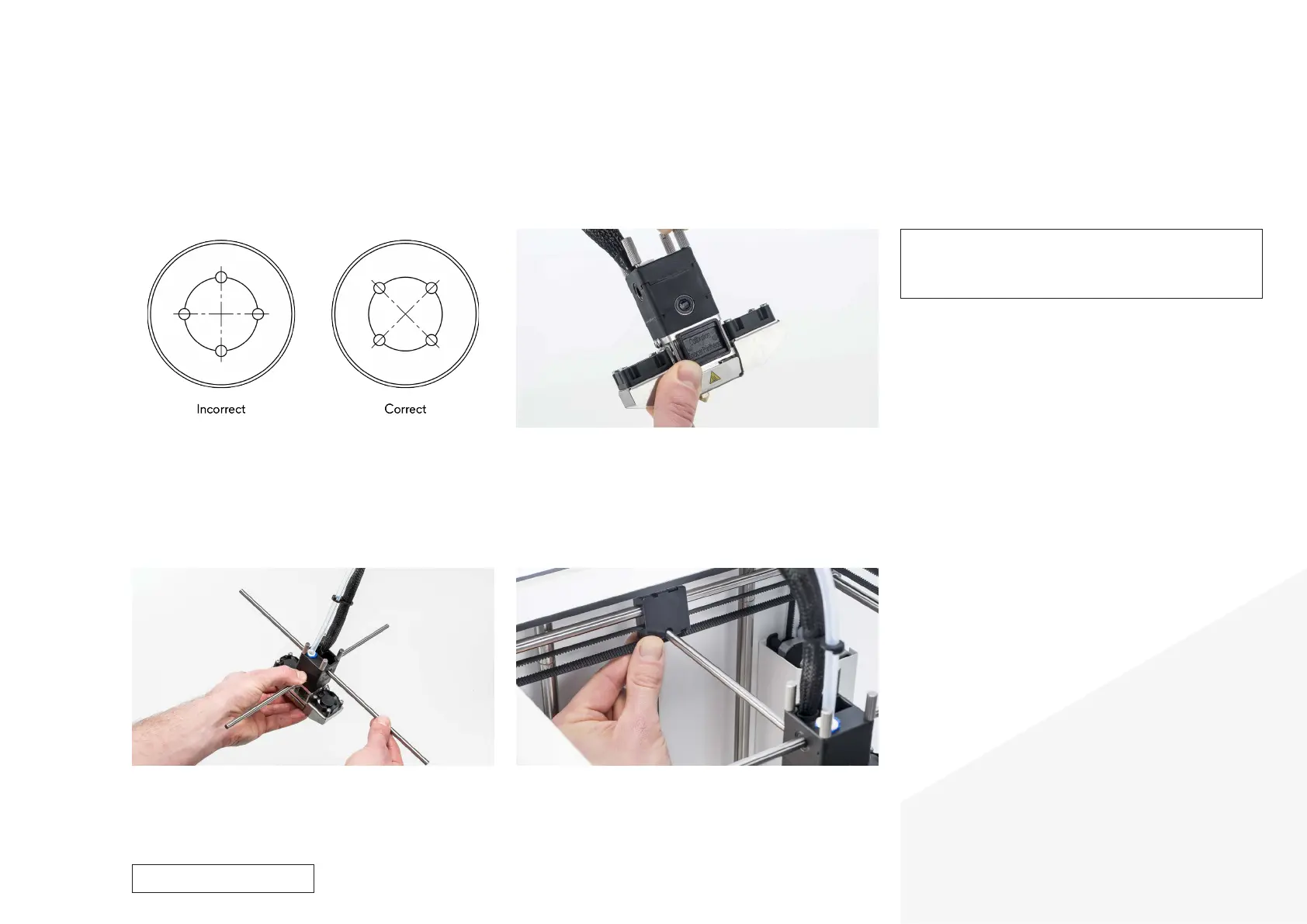

10. Align the linear bearings

• Look at the inside of the linear bearings and rotate them until they

are correctly orientated.

• The linear balls inside the bearing should be in an X shape. This is

to more equally divide the weight and pressure of the print head

over the bearings, which benefits printing quality.

Reassembly

11. Tighten the thumb screws

• Completely tighten the two thumb screws in the back by hand.

• To tighten the front two thumb screws, use the calibration spacer.

Place the tool in between the aluminum plates of the hot end.

• Tighten the front two thumb screws until the tool fits securely

between the plates, but can still easily be removed.

Caution: The print head alignment aid is very important to set

the correct pressure on the hot end. Securing the print head too

loosely may lead to leakages, while overtightening the thumb

screws will decrease the lifespan of the TFM coupler.

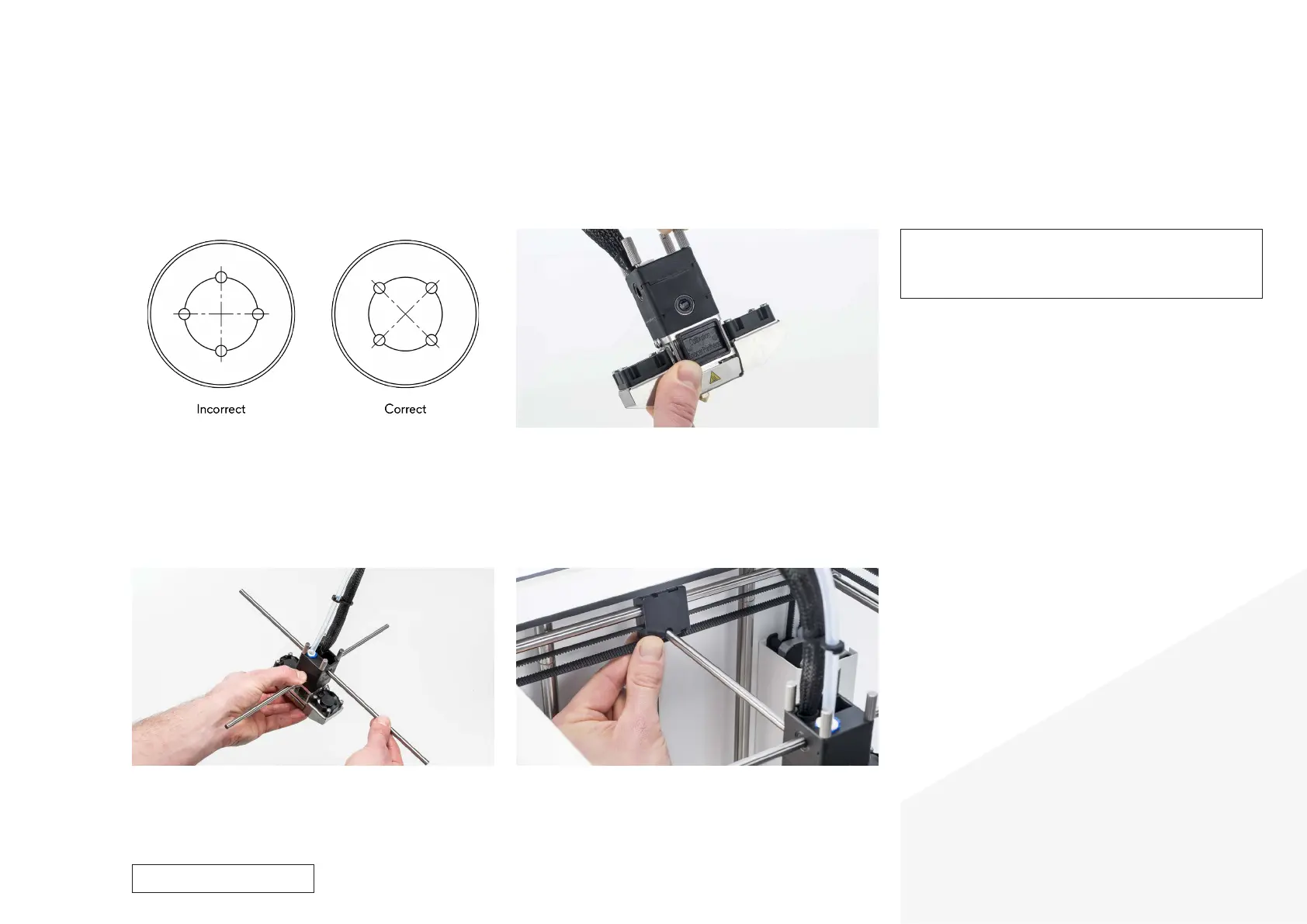

12. Insert the print head shafts through the print head

• The longer axle is the X print head shaft, it goes through the upper

linear bearing.

• The shorter axle is the Y print head shaft, it goes through the lower

linear bearing.

13. Place the print head back in the gantry system

• Put the print head in its original position and align the print head

shafts with their sliding blocks.

• Make sure that the ends of the axles are all in between the belts.

For internal use only

Loading...

Loading...