Do you have a question about the Ultimaker S5 and is the answer not in the manual?

Defines the intended application and scope for the Ultimaker S5 3D printer.

Provides additional information and warnings helpful for safe operation and problem avoidance.

Details potential risks including electrical, mechanical, thermal, and health hazards associated with the printer.

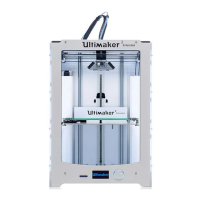

Identifies and labels the primary physical components of the Ultimaker S5 printer.

Lists the detailed technical properties, dimensions, and capabilities of the Ultimaker S5.

Step-by-step guide for safely unpacking the Ultimaker S5 from its protective packaging.

Lists all included accessories, consumables, and tools provided with the Ultimaker S5.

Instructions for connecting essential hardware accessories like Bowden tubes and the NFC spool holder.

Guides the user through selecting and confirming the build plate during the initial printer setup.

Details the process of installing the interchangeable print cores into the printer's print head.

Step-by-step instructions for loading filament spools into the feeders and print head.

Explains how to connect the printer to a network and update its firmware.

Guide on downloading and installing the necessary Ultimaker Cura software on a computer.

Explains the printer's main menu, interface options, and navigation via the touchscreen.

Provides a table detailing material compatibility with different print core sizes.

Offers advice on recommended build plates and settings for various printing materials.

Overview of the Ultimaker Cura interface for model preparation, settings, and slicing.

Instructions on how to slice a 3D model using Ultimaker Cura, including adjustment tools.

Details how to initiate a print job using Cura Connect over a network.

Instructions for transferring and printing files to the Ultimaker S5 using a USB stick.

Methods for safely detaching completed prints from the build plate.

Procedures for dissolving PVA supports in water and removing Breakaway supports.

How to change materials, print cores, or build plate settings via the printer's menu.

Explains build plate leveling, active leveling, and XY offset calibration processes.

Instructions for updating the printer's firmware via network or USB.

Guidelines for storing filament materials to maintain optimal quality and usability.

Recommended schedule for performing routine maintenance tasks on the printer.

Instructions for cleaning the printer's build plate.

Guide for cleaning printer glass parts and print head nozzles.

Procedure for cleaning filament pathways within the Bowden tubes.

Steps to remove material debris from the printer's interior.

Steps for applying oil to the X, Y, and Z axles for smooth stage movement.

How to check for and address any looseness or play in the printer's axles.

Procedure for checking and adjusting the tension of the short belts for accurate print head movement.

How to inspect and clear debris from the print head's cooling fan.

Instructions for inspecting the nozzle cover and procedures for replacement.

Steps for lubricating the Z motor's lead screw to ensure smooth vertical movement.

Guide on removing and cleaning filament particles from the feeder gears and housing.

Detailed instructions for cleaning print cores using hot and cold pull methods.

Steps for lubricating the feeder gears to ensure smooth filament feeding.

Procedures for disassembling and replacing the Bowden tubes.

Instructions for cleaning the system fans located at the back of the printer.

Procedure for lubricating the hinges of the printer's glass doors.

Lists common error messages encountered on the Ultimaker S5 and points to solutions.

Addresses common issues with print cores, such as clogging or not being recognized.

Covers common print quality problems like poor adhesion, grinding PVA, and under-extrusion.

| Build Volume | 330 x 240 x 300 mm |

|---|---|

| Layer Resolution | 20 - 600 microns |

| Filament Diameter | 2.85 mm |

| Max Nozzle Temperature | 280 °C |

| Max Build Plate Temperature | 140 °C |

| Print Technology | Fused Filament Fabrication (FFF) |

| Number of Print Heads | 2 |

| Build Plate | Heated glass build plate |

| Operating Sound | 50 dBA |

| Print Speed | Up to 24 mm³/s |

| Display | 4.7-inch color touchscreen |

| Operating Temperature | 15 - 32 °C |

| Nozzle Diameter | 0.25, 0.4, 0.6, 0.8 mm |

| Connectivity | Ethernet, Wi-Fi, USB |

| Supported Materials | PLA, ABS, Nylon, CPE, PVA, TPU 95A, PC, PP |

| Dimensions | 495 x 585 x 780 mm |

| Feeder Type | Dual-geared |

| Print Head Movement Speed | 300 mm/s |

| Build Plate Heating Time | Less than 4 minutes |

| Power Consumption | 350 W |

| Travel Speed | 300 mm/s |

| Operating Humidity | 20 - 80% (non-condensing) |