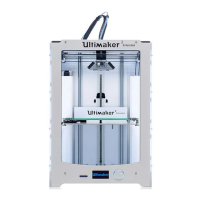

Ultimaker S5

Fine knurl feeder kit

Notes

Caution: Make sure the laments are removed, the Ultimaker

S5 is turned o, and the power cable is disconnected from the

printer before you start the replacement.

Introduction

This document describes how to replace both of the feeders of the Ultimaker S5. A new feeder with a ner knurled wheel was developed

to improve printing with PVA on the Ultimaker S5 Pro Bundle. The ne pattern of the knurled wheel reduces stress on the PVA material

and prevents it from breaking inside the Material Station. These new feeders are strongly recommended for the Ultimaker S5 Pro Bundle if

PVA is used regularly.

EN 02/2021 v2.1 Original instructions

Requirements

For this repair, you need a new set of feeders (provided

in the Fine knurl feeder kit) and a 2 mm hex screwdriver.

Optionally, you can use grease to perform maintenance

on the feeder gear while performing this replacement.

The screwdriver and grease were included in the

Ultimaker S5 accessory box.

• Fine knurl feeder left (1)

• Fine knurl feeder right (2)

• 2.0 mm hex screwdriver

• Magnalube grease (optional)

Note: Both of the feeders must be replaced. The two versions

cannot be mixed on the same printer. Keep the ne knurl feeders

in the kit until the old feeders have been removed. Ensure to

keep them separate.

The new feeders have been marked with a black dot on the back.

Loading...

Loading...