47

Installation instructions

ENGLISH

Second phase – Cleaning

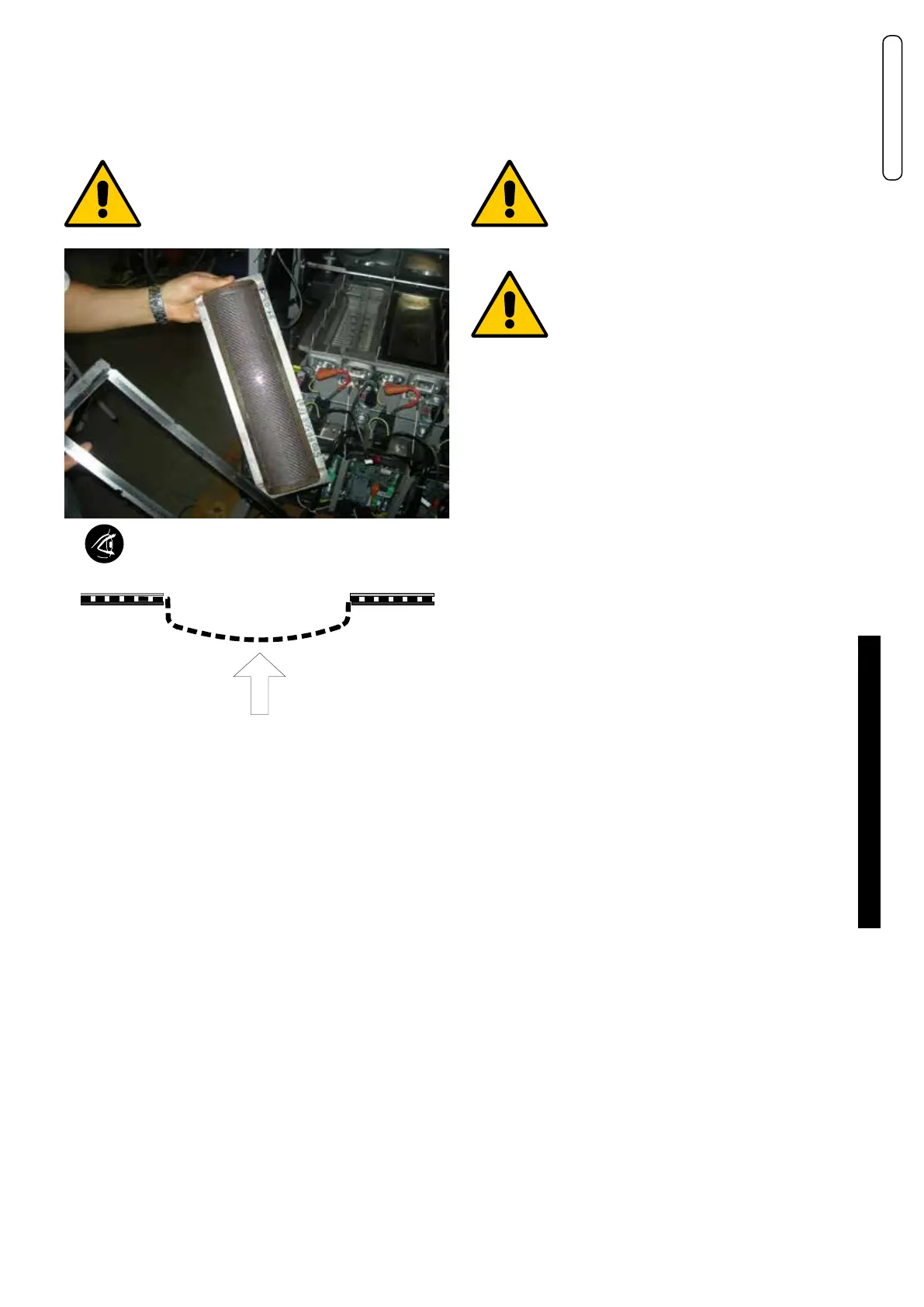

• Remove the gaskets and the burners.

• Dry clean the burners by blowing compressed air from the

“ame side”

• Visually inspect the welding on the corner pieces and on the

burner mesh.

The burner gaskets must be replaced at each

cleaning operation.

• Wash the combustion chamber with water, taking care not to

wet the electrical wiring.

During this operation, make sure that the condensate drain

pipe always remains clear so that the washing water does

not leak from the inspection opening.

• Blow the combustion chamber with compressed air, trying to

remove any dirt still attached to the pins.

• When the parts have been washed, make sure that the con-

densate drain trap is clear: clean it if necessary

• Inspect the ue gas exhaust pipe and the ue

Third phase – Re-assembly

When reassembling, proceed in reverse

order, taking care to tighten the fastening

screws of the mixer/fan unit to the body, with

13 Nm tightening torque

ATTENTION

AT EACH MAINTENANCE OPERATION, IT IS

MANDATORY TO REPLACE THE SEALING

GASKETS OF EACH BURNER.

• Before ignition, check that the condensation drain trap is

properly lled with water.

• Before opening the gas supply valve again make sure that

the previously loosened gas tting, is tight. To do this, open

the valve and check its seal with soapy solution.

• As a burner ignites, immediately check the seals between

each individual gas valve and its premixing chamber

• Analyse the combustion and check its parameters.

• Make sure that all opened gas pressure sockets are closed.

• After cleaning the body and/or burners, put the burners back

in their seats

• Position the new gaskets.

COMPRESSED AIR

Loading...

Loading...