FOR OPERATORS AND SUPERVISORS

FOR OPERATORS AND SUPERVISORS

INSPECTIONINSPECTION

1-121-12

■■

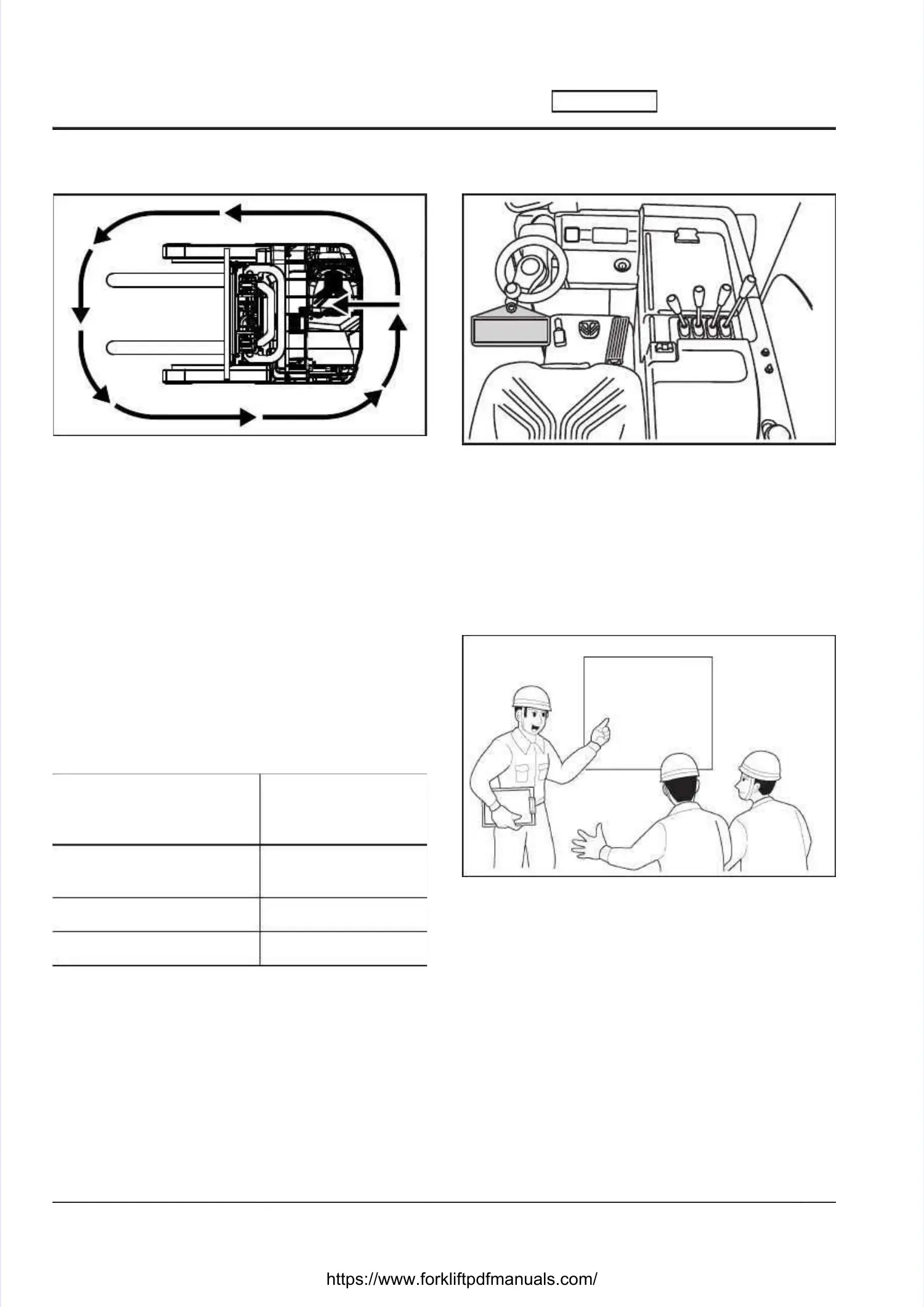

ALWALWAAYS IYS INSPECT NSPECT BEFOREBEFORE

OPERATINGOPERATING

The operator should always inspect the truck beforeThe operator should always inspect the truck before

each work shift to ensure that all essential safetyeach work shift to ensure that all essential safety

features are working. Any abnormality must befeatures are working. Any abnormality must be

reported to the supervisor, who is responsible forreported to the supervisor, who is responsible for

correcting it.correcting it.

■■PERIODIC INSPECTIONS AREPERIODIC INSPECTIONS ARE

MANDATORYMANDATORY

Monthly and annual inspections must be performedMonthly and annual inspections must be performed

thoroughly, and any abnormality promptly repaired.thoroughly, and any abnormality promptly repaired.

Only a certied expert who has the advanced skillsOnly a certied expert who has the advanced skills

and equipment is allowed to conduct inspections.and equipment is allowed to conduct inspections.

■■ REPLACE SAFEREPLACE SAFETY PARTS REGULARLTY PARTS REGULARLYY

Names of the safety partsNames of the safety parts

RecommendedRecommended

replacement intervalreplacement interval

(year)(year)

Load handling systemLoad handling system

hydraulic hosehydraulic hose

1 – 21 – 2

LLiifft t cchhaaiinn 2 2 – – 44

EElleeccttrroommaaggnneettiic c bbrraakkee 9 9 – – 1100

Certain critical parts must be replaced at regularCertain critical parts must be replaced at regular

intervals. Since it is difcult to detect wear on theseintervals. Since it is difcult to detect wear on these

parts by visual inspection, they must be replacedparts by visual inspection, they must be replaced

at the specied intervals, because a failure wouldat the specied intervals, because a failure would

result in a falling load or runaway truck.result in a falling load or runaway truck.

■■

NEVER USE AN UN-MAINTAINEDNEVER USE AN UN-MAINTAINED

TRUCKTRUCK

DO NOTDO NOT

OPERATEOPERATE

A A truck truck that that has has failefailed d an an inspeinspection ction must must not not bebe

operated. Hang a sign in the control area that saysoperated. Hang a sign in the control area that says

DO NOT OPERATE and remove the key, to makeDO NOT OPERATE and remove the key, to make

sure no one uses it. Then report the problem to thesure no one uses it. Then report the problem to the

supervisor and wait for repairs to be completed.supervisor and wait for repairs to be completed.

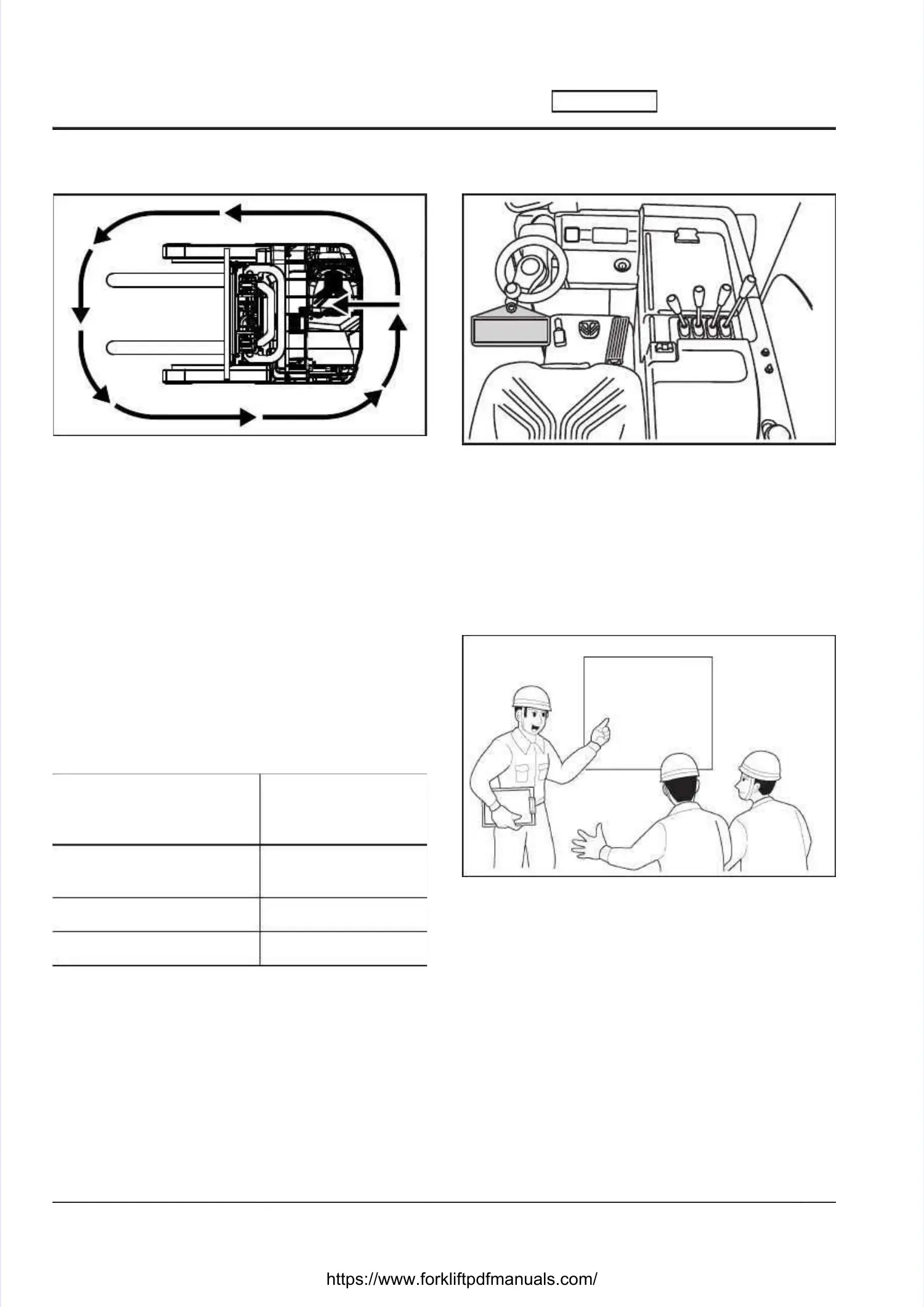

■■DESIGNATE A REPAIR AND DESIGNATE A REPAIR AND ASSEMBLYASSEMBLY

SUPERVISORSUPERVISOR

1. Preparation1. Preparation

2. Removal2. Removal

3. Disassembly3. Disassembly

4.4.

Repairs and the mounting and dismounting ofRepairs and the mounting and dismounting of

attachments must be performed under the directionattachments must be performed under the direction

of a designated supervisor. The body and majorof a designated supervisor. The body and major

parts of the lift truck are quite heavy and under veryparts of the lift truck are quite heavy and under very

high pressure. Repair or assembly work undertakenhigh pressure. Repair or assembly work undertaken

without careful and thorough preparation can leadwithout careful and thorough preparation can lead

to serious to serious injuryinjury..

Loading...

Loading...