ACCESSORIES

Section 8-4

Making the Connections

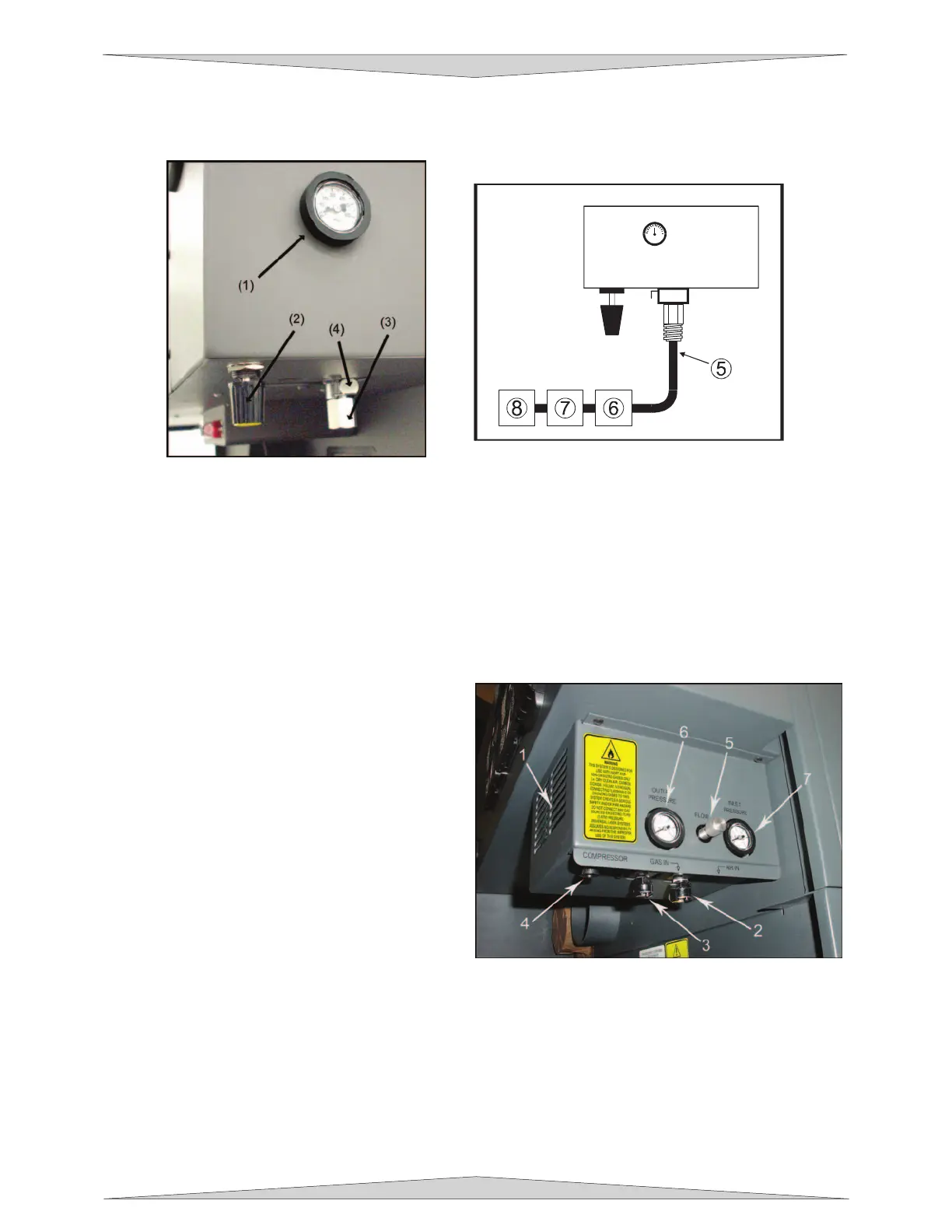

Standard Air Assist style

In the left rear part of the system you will find the pressure gauge (1), flow adjustment valve (2), quick

release coupling (3), and release lever (4).

Push in the release lever and pull down on the quick release coupling to remove it from the machine.

Attach your compressed air supply hose to this fitting (1/4 NPT threads) and use Teflon tape on the

threads to prevent leaks. Re-insert the fitting until it “clicks” into place.

Attach the other end of the supply line (5) to a particulate filter (6), desiccant/dryer (7), and then to an oil-

free compressed air source (8).

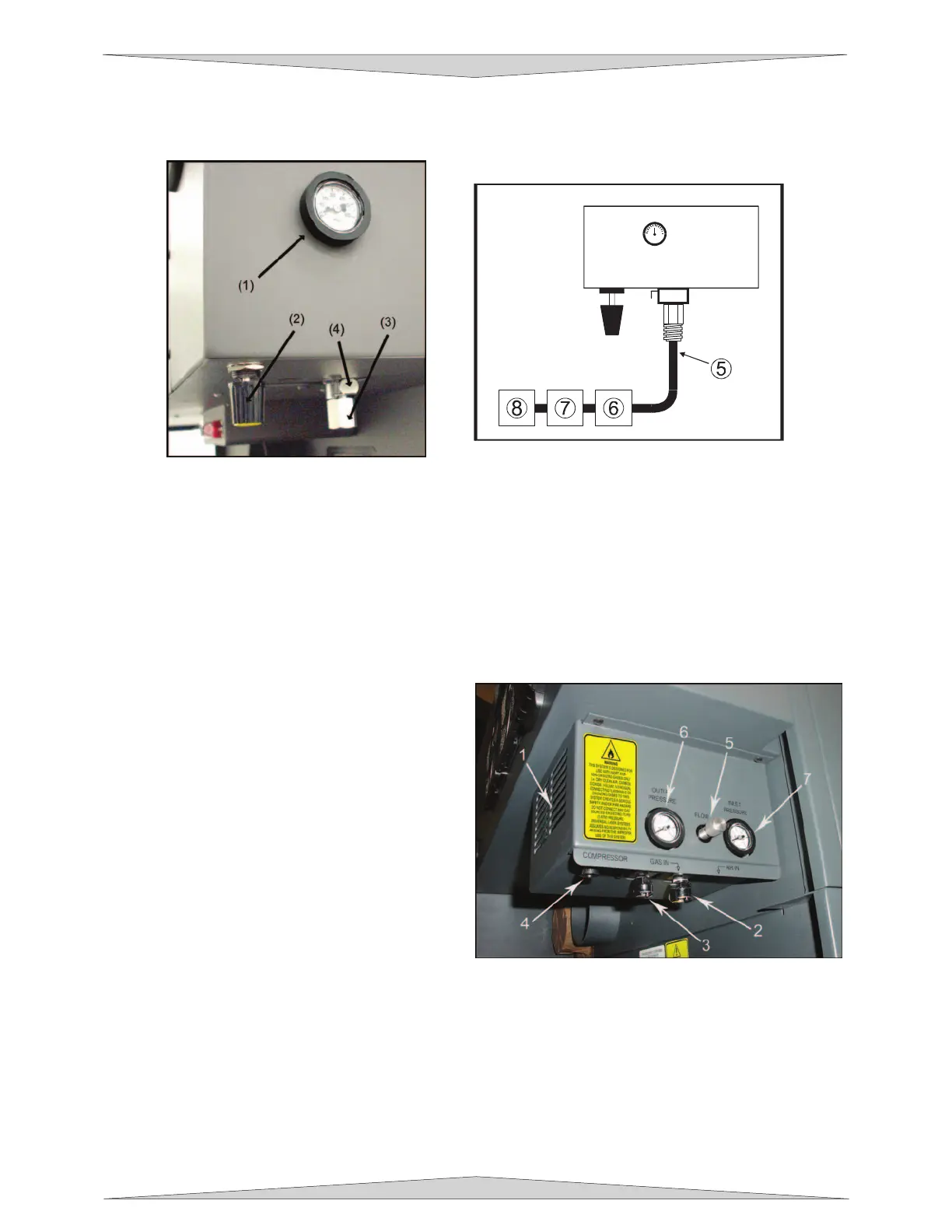

Computer Controlled Air Assist style

In the left rear part of the system you will find the

Air Assist control box. Attached to the box (not

shown in picture) there should be two special

quick release couplings secured with plastic tie

wraps (1). Using a pair of scissors or wire cutters,

cut off the plastic tie wraps and discard.

The AIR IN (2) fitting is where you attach the

compressed air supply. The GAS IN (3) fitting is

where you would attach an inert gas supply

(optional). If you purchased the optional Air

Compressor, you would connect the control wire to

the COMPRESSOR (4) connector (refer to the Air

Compressor instructions for more details). The

FLOW knob (5) is used to adjust airflow to the

work piece (through the cone) during operation.

You can monitor the pressure by observing the pressure gauges (6 & 7) during operation.

Loading...

Loading...