ACCESSORIES

Section 8-5

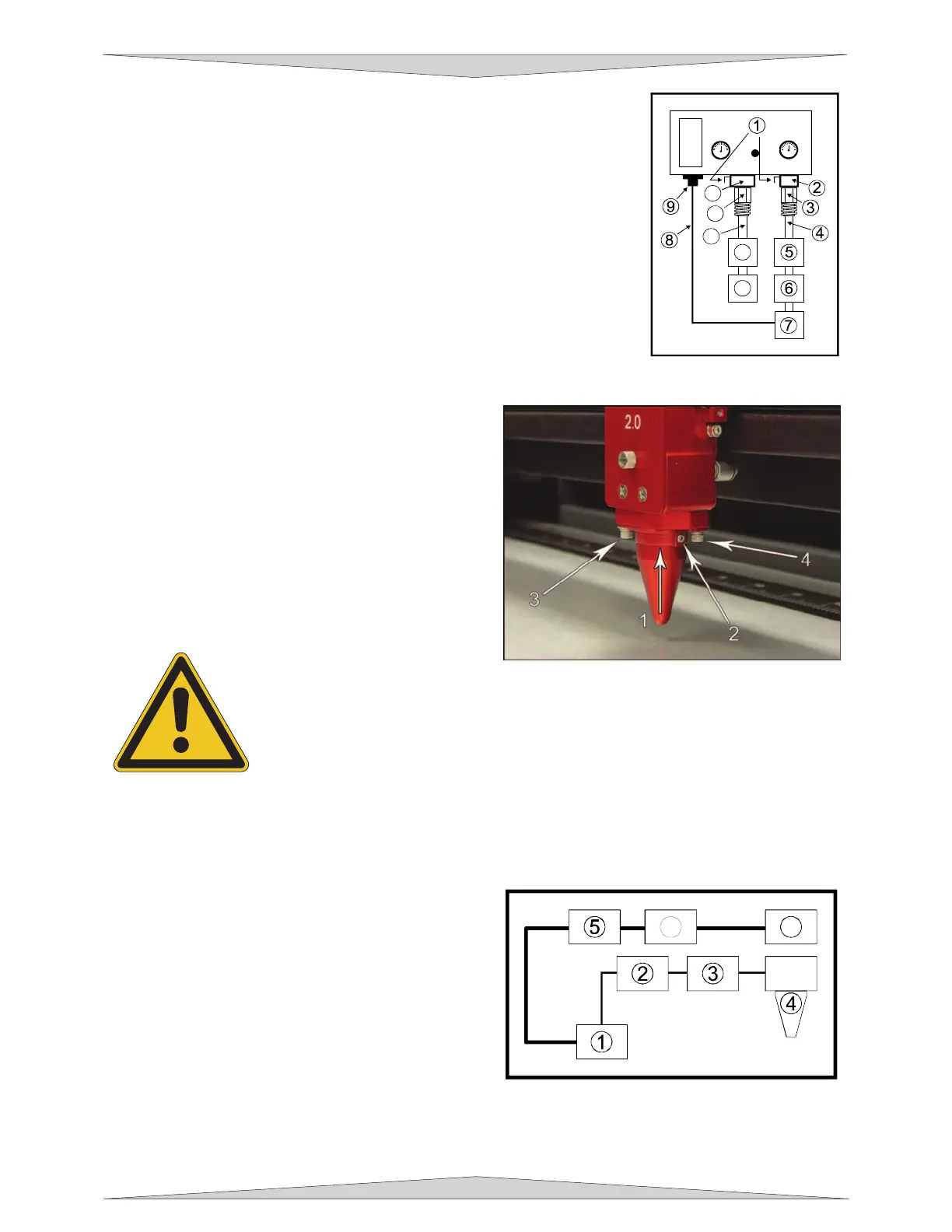

Locate the locking lever (1) attached to both fittings. Push in the lever until

it clicks. Attach the larger quick release coupling (3) (1/4 NPT threads) to

your compressed air supply line (4). Use Teflon tape on the threads to

prevent leaks. Push the quick release coupling (3) into the fitting (2) until it

clicks into place. Attach the other end of the supply line (4) to a particulate

filter (5), desiccant/dryer (6), and then to an oil-free compressed air source

(7). If you have purchased the optional Air Compressor, connect the control

wire (8) from the compressor (7) to the COMPRESSOR connector (9). If

using an inert gas, attach the smaller quick release coupling (11) (1/4 NPT

threads) to the supply line (12) using thread sealant or Teflon tape. Push

the quick release coupling (11) into the fitting (10) until it clicks into place.

Attach the other end of the supply line (12) to an external pressure regulator

(13) and then on to the gas tank (14).

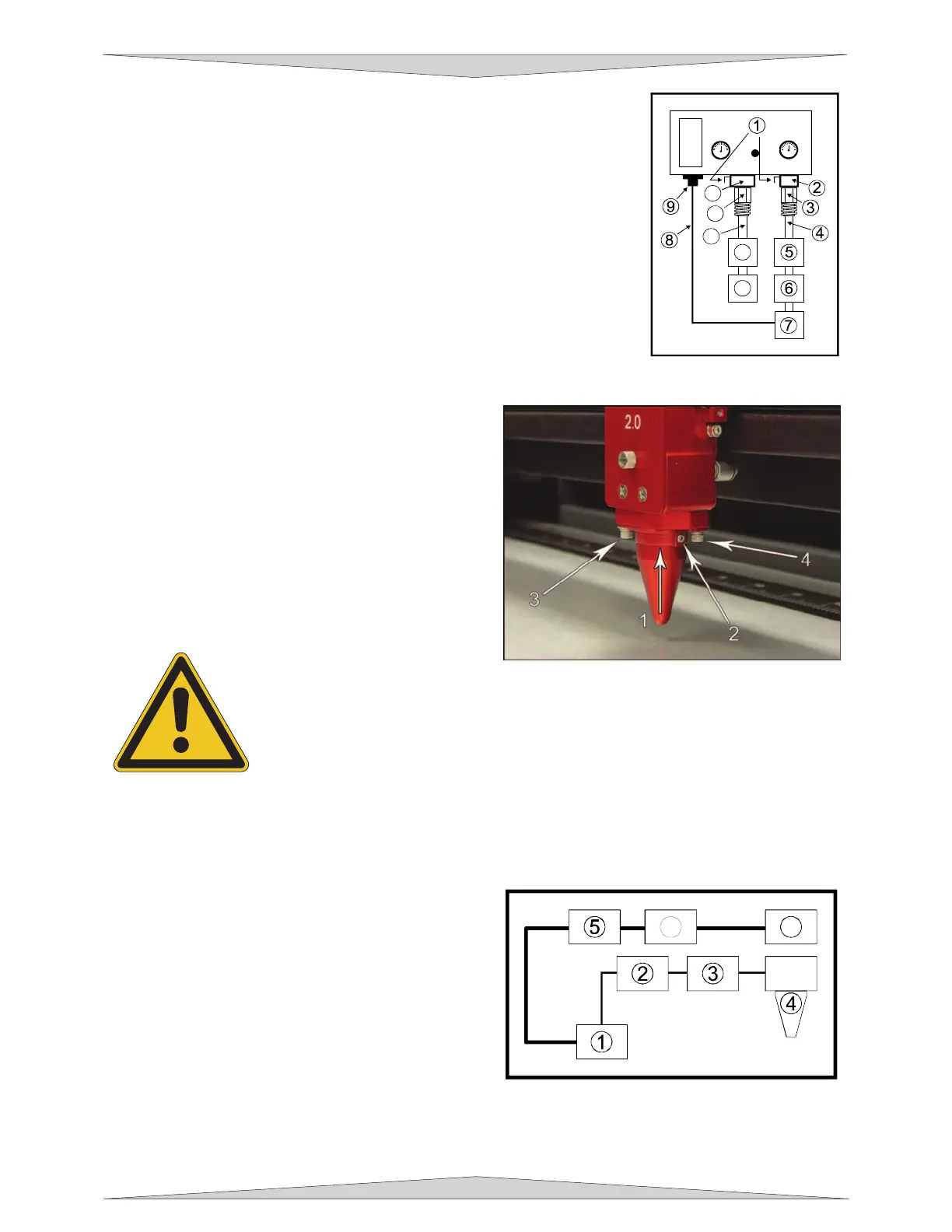

Cone Installation and Removal (both styles)

The cone must be attached to direct the air or gas

supply to the laser beam's focus point. To install the

cone, insert the cone (1) into the cone base completely

until it bottoms out. Using a .050 inch Allen wrench,

tighten the setscrew on the side of the cone base (2)

until it is snug. Re-check to make sure that the cone is

all the way into the base and is not tilted. To remove

the cone, simply loosen the setscrew (2) and pull the

cone straight down. DO NOT remove or loosen the

cone base mounting screws (3) & (4) to mount or

dismount the cone. These screws keep the cone base

aligned with the laser beam.

DO NOT install the cone unless you plan on using Air Assist. Leaving the cone

attached to the cone base and running the laser system without either air or gas

flowing through the cone will destroy the focus lens within a few minutes. If you are

not using Air Assist, REMOVE THE CONE. Damage of this nature is due to

neglect and WILL NOT be covered under warranty.

How it Works

Standard Air Assist

The Quick Release Fitting (1) is the entry point into the

rear enclosure of the laser system. From there, the air

lines branch off into two paths, the optics protection

path and the cone path. The optics protection path is

a direct path from the quick release fitting (1) to the

beam window (5), the #2 mirror (6), and the #3 mirror

(7). Since this is a direct path, the amount of air

pressure and flow that is coming from your

compressed air source will be applied to the optics to

help keep them clean from flying debris. The cone

path goes through the adjustment valve (2), to the

gauge (3), and then to the cone (4). The amount of air, flowing through the cone, is adjusted using the

adjustment valve (2) and monitoring the pressure displayed on the gauge (3). The cone path protects the

focus lens and provides a downward flow directly into the beam path at the focus point.

11

12

13

14

10

6 7

Loading...

Loading...