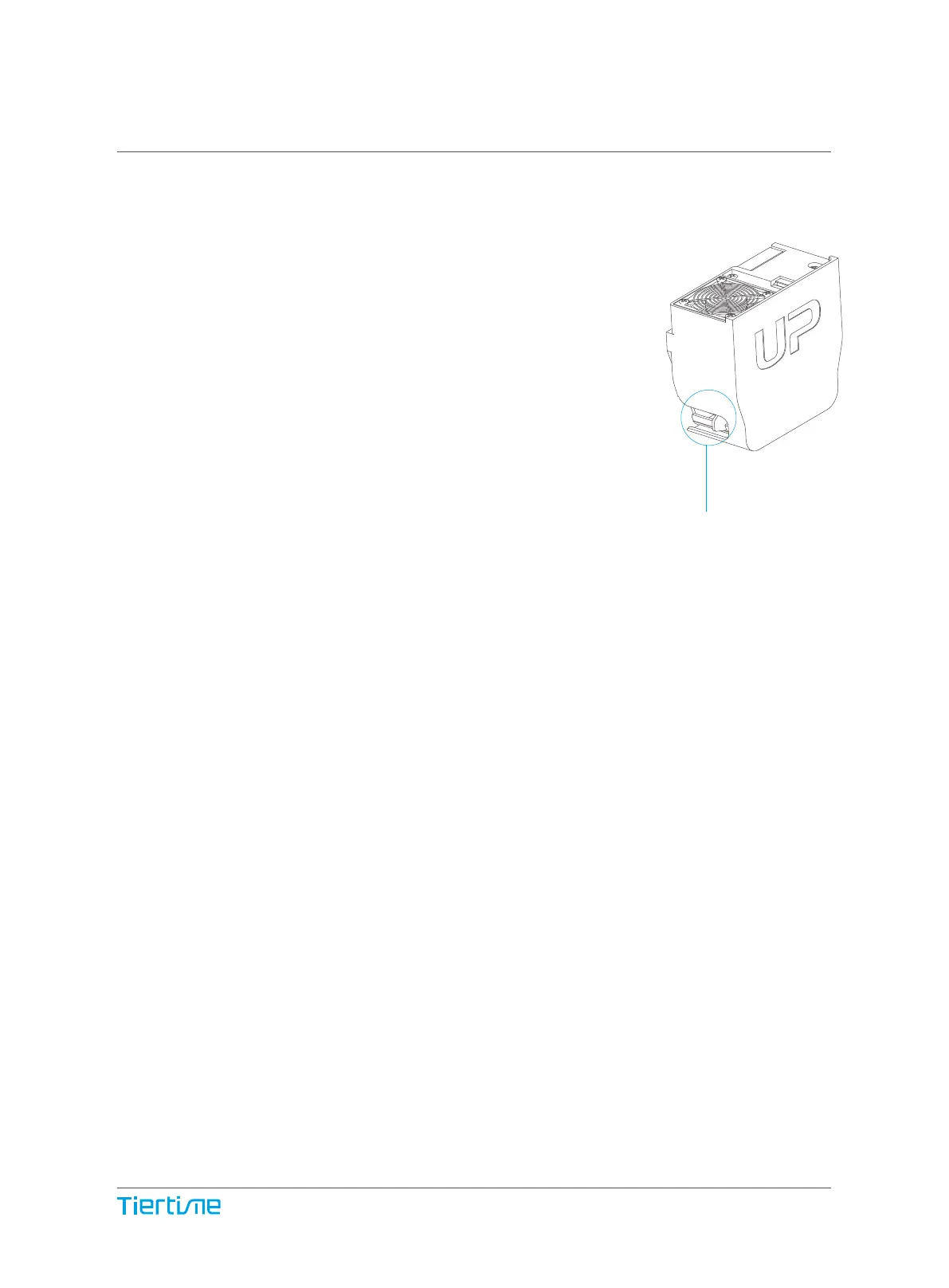

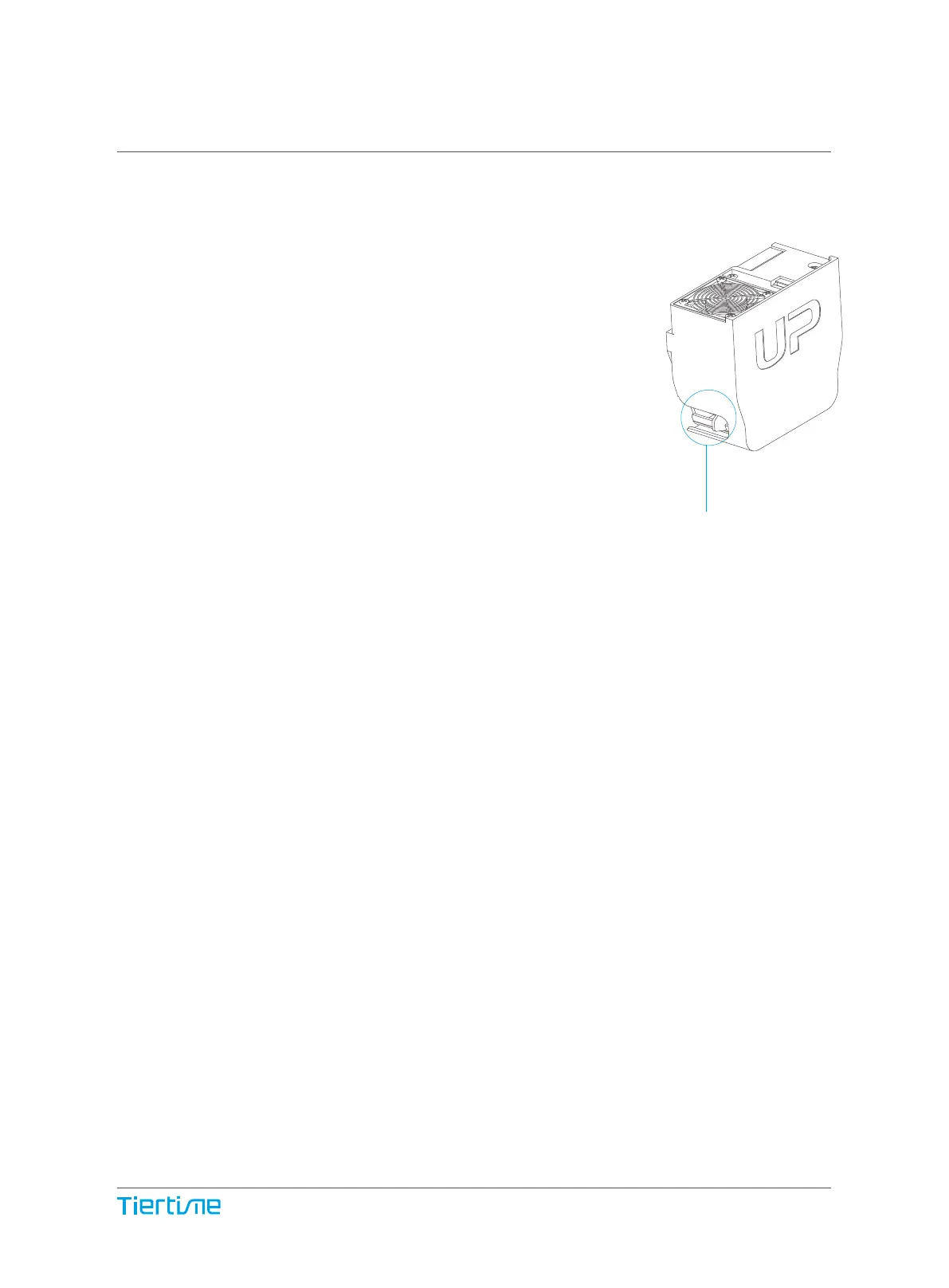

Air Flow Adjustment

knob

Printing Techniques

1. Ensure optimal nozzle height. If the nozzle height value

is too low, it will cause warping; if it is too high, it will crash

the nozzle into the platform,causing damage and clog-

ging. You can manually fine-tune the nozzle height value

in the"Calibation"panels.You can try to adjust the nozzle

height value plus or minus 0.1–0.2mm from the base on

previous saved nozzles heights.

2. Calibrate the printing platform well. An unleveled plat-

form usually causes warping.

3. Allow enough time for sufficient preheating.A well

preheated platform is essential for printing large objects

without warping.

4. The airflow on print head is adjustable, slide the air flow

adjustment knob to change the amount of cooling direct-

ed onto the printed object. Generally the more cooling

provided, the better the print quality. Cooling also help

with support and raft removal. However cooling also

encourage wrapping, especially for ABS.

To generalize, PLA can take strong cooling without prob-

lem,while ABS should avoid cooling or give little cooling.

For ABS+ medium cooling is recommended.

5. Printing with no raft. It is highly recommended to use

raft for normal printing as it improves adhesion and is

required for leveling compensation. It is turned on by

default, but you can turn it off in the "Print Preference"

panel.

6. Printing with no support. It is possible to print with out

supporting structures.You can turn off support by choos-

ing "No Support" in the "print" setting panel.

49

Loading...

Loading...