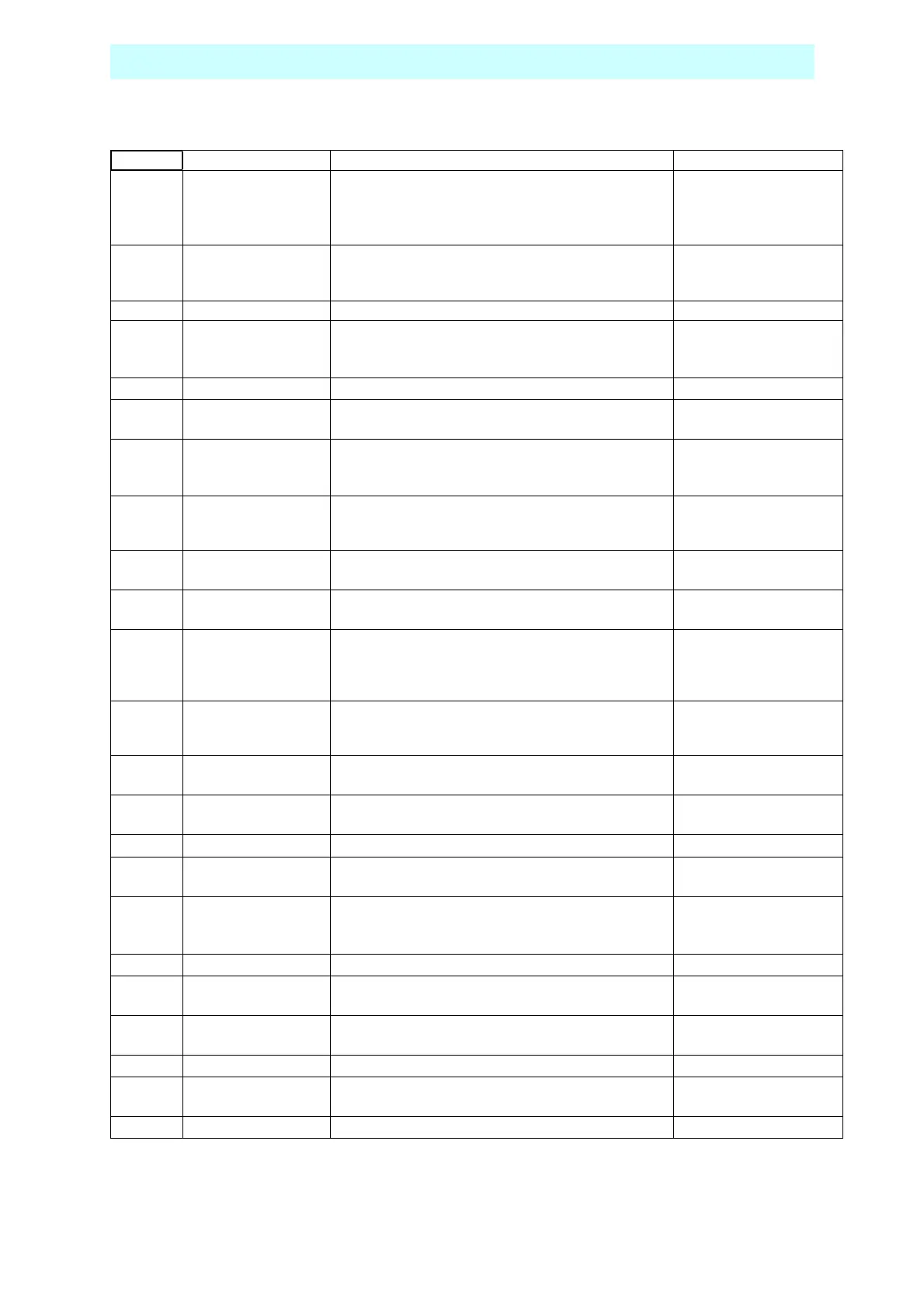

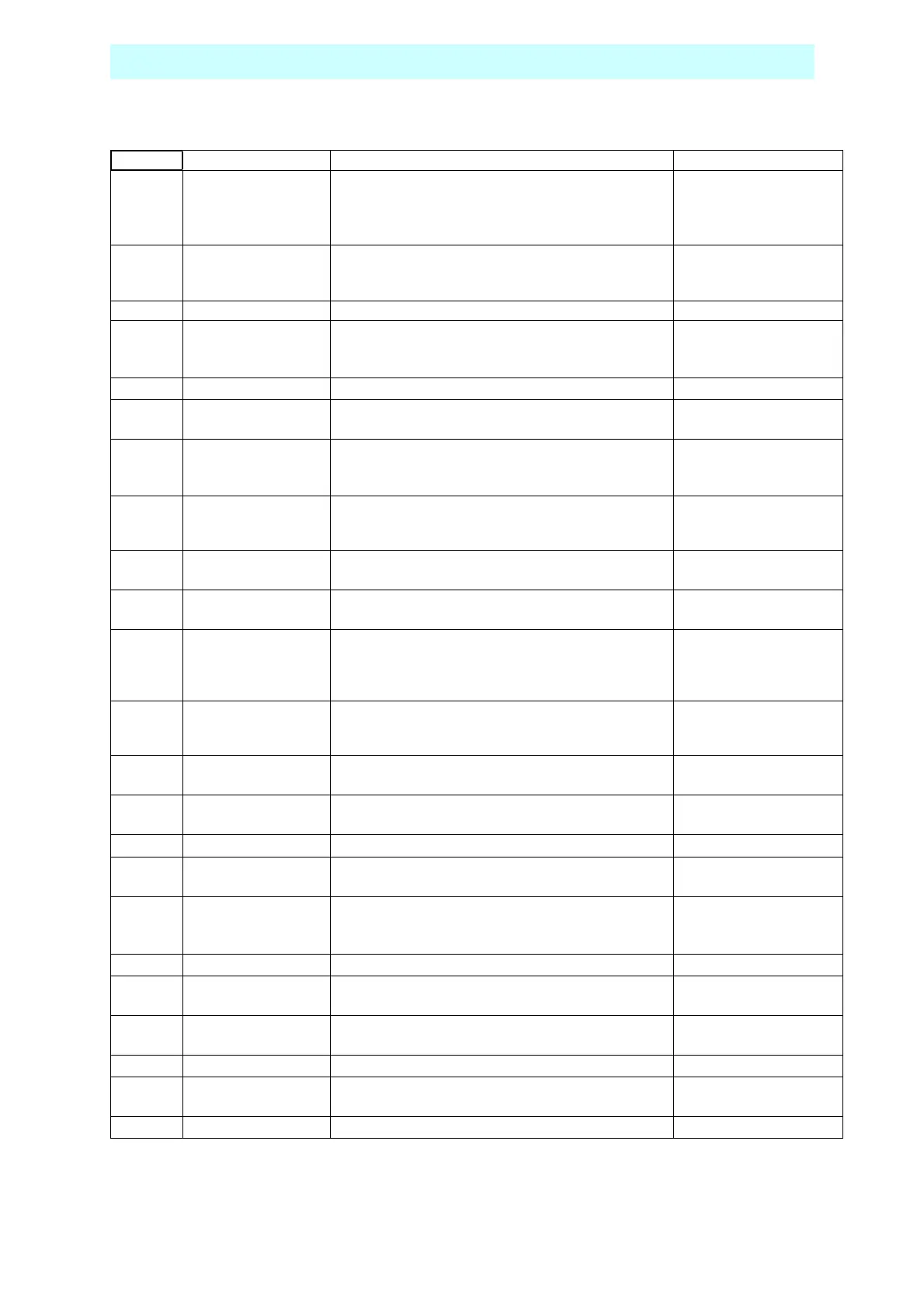

15

SECTION

DAILY CHECKS ACTION NOTES

1

Hydraulic System Top up with machine standing on level ground in

the travelling position. Fill oil using the return line

filter on top of the tank. Oil must be at the bottom

mark on the dipstick. Look for oil leaks.

Use SHF22 oil or

equivalent. Change oil

and filter every 6

months

2 I.C. Engine Check oil, filter and fuel. Check for leaks. Check

battery. Top up with distilled water only. 6 mm

above plates.

See OEM manual for

more information

3 Level Gauge Check that level gauge is present and secure

4 Physical damage Check for physical damage to the booms, tie

bars, basket, slew and the chassis. Check all

warning labels are in place

Do not use damaged

machine

5 Nuts, Bolts, Fittings Check for missing and loose nut and bolts. Replace immediately

6 Locking pegs Check that all locking pegs are present. Check

that no shafts are seized.

Broken peg = seized

shaft

7 Transport locks &

Lifting points

Check that all transport lock pins are present.

Check for damaged lifting points

Do not transport

machine without locking

pin.

8 Battery & Charging If fitted. Check operation of charger. Record

specific gravity of each cell. Clean top of battery.

Clean and check terminal

9 Emergency stop Check that all emergency stop switches are

working

Turn to release

10 Electrical system Check for correct operation of the complete

electrical system

11 Electrical Safety

system

Check that you can not operate the booms until

outriggers are down and in contact with ground.

Check that you can not raise the outriggers with

top or bottom boom elevated.

1 Hydraulic Safety

system

Check that all emergency lowering valves work.

Check emergency slew. Check emergency

handpump

12 Wheels Check tyres for damage. Wheel nuts and tyre

pressure

55PSI 3.8 Bar

13 Running gear Check parking brake. Check overrun device.

Check for damage

14 Trailer lights Check for correct operation if towing

WEEKLY CHECKS Depending on use and operating condition

different intervals may be acceptable

15 Lubrication All grease nipples. Depending on machine use

and operating condition different intervals may

be acceptable.

16 Slew Gear Check slew gear for excessive wear. Grease

MONTHLY CHECKS Can be done 6 monthly depending on operating

conditions

1 DC motor Check and replace motor brushes if machine is

used heavily

2/3 worn = Replace

13 Wheel bearings Check for wear - Do checks at every 3000 miles

6 MONTHLY

CHECKS

16 Thorough Inspection Contact UpRight or its local representative. Change oil and filter !

MAINTENANCE SCHEDULE

Loading...

Loading...