16

Power Pack.

The hydraulic system is fully self contained. Oil tank

capacity is 15 Litres. When operating above 0C we

recommend using ISO22 Grade Hydraulic Mineral Oil

(See Health & Safety guidelines supplied with the oil

prior to handling).

Replace oil and filter every 6 months. The biggest

cause of hydraulic problem, sticking valves, leaking

cylinders etc.. are due to contaminated oil. There is no

need to replace the oil in the hoses. Just replace the

oil in the tank.

The return line filter doubles as the oil filler cap. No oil

is used by the system so if oil is required this would

indicate an oil leak which must be investigated prior to

using the machine.

Correct Oil Level.

It is critical that the correct oil level is maintained. Too little oil will cause cavitation and

failure of the pump. Too much oil will lead to oil leak through the return filter breather or a

massive oil leak when using the emergency lower valves on the top and bottom boom. The

rams are double acting. When using the emergency lower valves you require free space in

the tank to accommodate oil which normally would be pumped into the annular side of the

cylinder. If this should happen, just clean up the oil spillage. Fully extend ALL rams. Then

close up all rams and check the free space in the tank using the dip stick. Oil must be at the

bottom mark on the dipstick to ensure correct level.

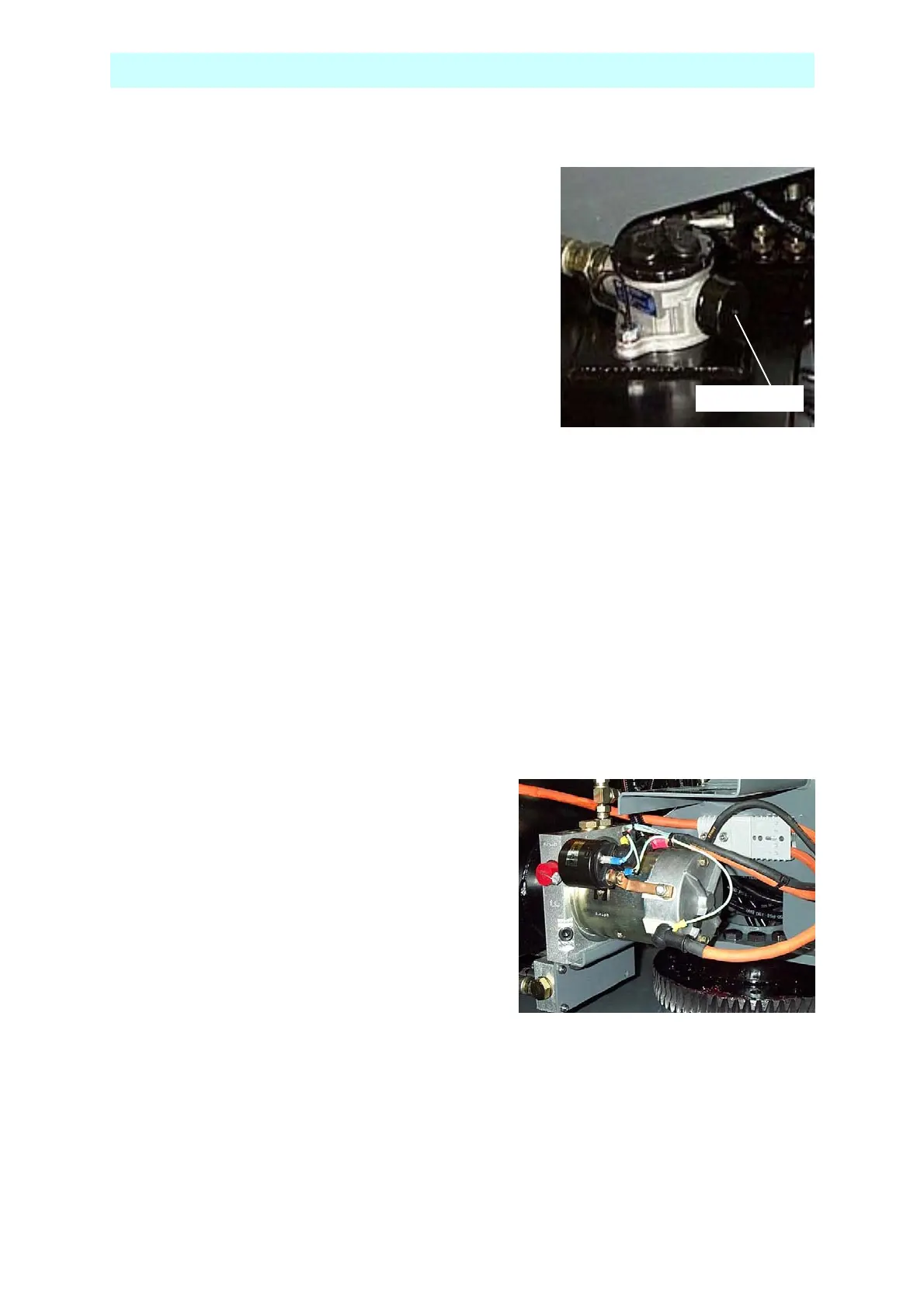

DC Motor & Pump.

The hydraulic pump is submerged in the tank. Oil

is drawn in through a suction strainer protecting

the pump. The DC motor (shown) is directly

coupled to the pump shaft. On AC motor a small

adapter coupling is used between the motor and

pump shaft. To replace the pump the tank must

be removed. Remove the power pack from the

machine. The tank is secured with 4 bolt.

Remove the tank. The pump is bolted to the

aluminium block containing the relief valve

(Hidden under the red cap shown here - Relief

valve is factory set to 210Bar). Remove the 4

fixing bolts securing the pump.

Filter Breather

MAINTENANCE PROCEDURE

Loading...

Loading...