46

The slew stop mechanism is fully lubricated and should normally not require any further lubri-

cation. Should more lubrication be needed this can be done in two ways.

1) When greasing the slew bearing some grease will drop in to the centre part of the slew.

Keep on greasing the slew bearing until you can see grease escaping from the outside

sealing lip on the slew gear. Keep on greasing, The grease will now be pushed out

through the outer and inner sealing ring of the slew bearing. Grease escaping from the

inner seal will drop onto the slew stop ring

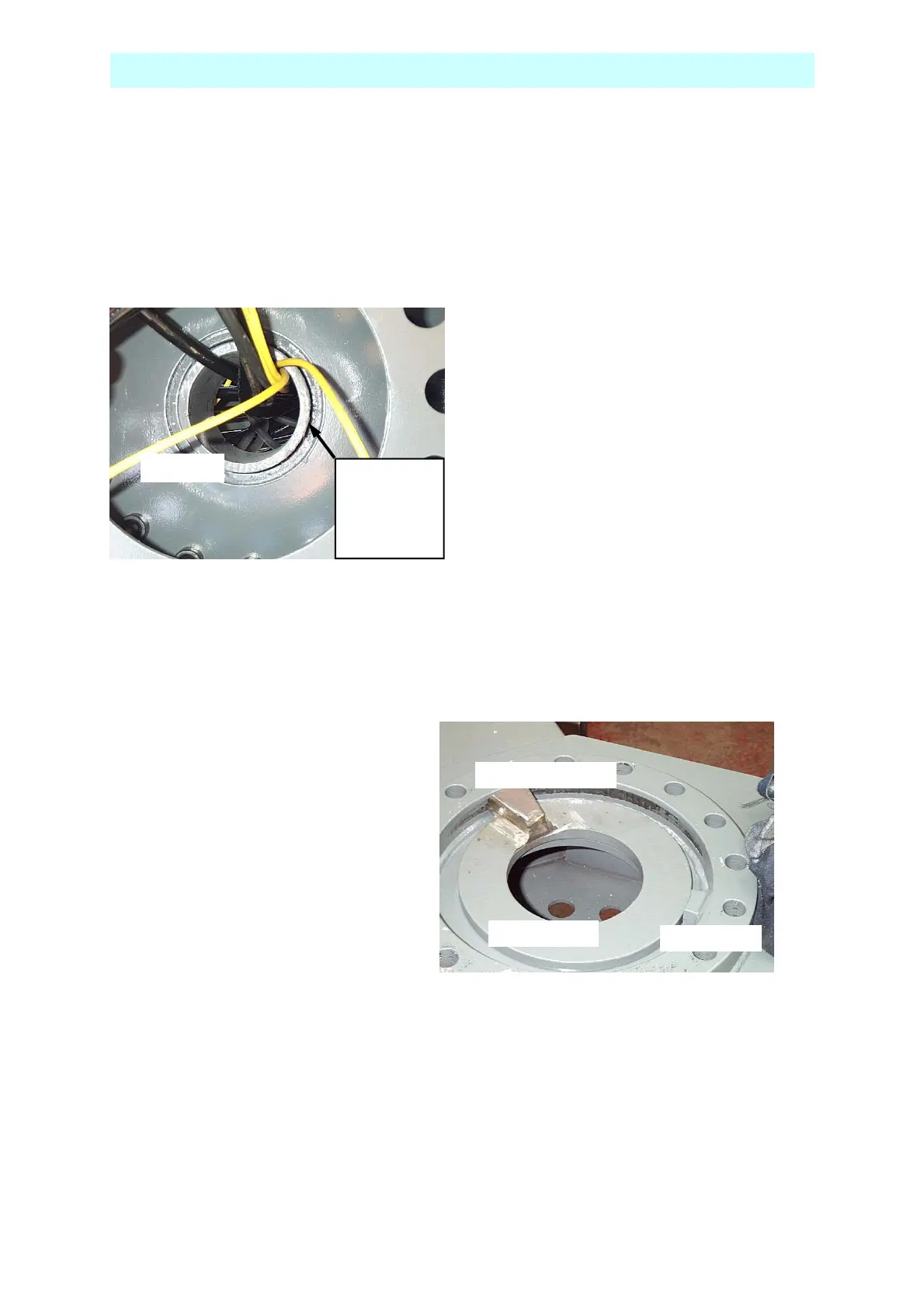

2) You can also spray LPS-3 lubrication up between the Slew tube and the chassis plate.

How does the slew stop work ?

The slew stop mechanism is very simple and prevent the cables and hoses getting tangled

up by continuous rotation. The Slew stop ring will allow the operator to turn almost 360 deg

in each direction from the stowed position.

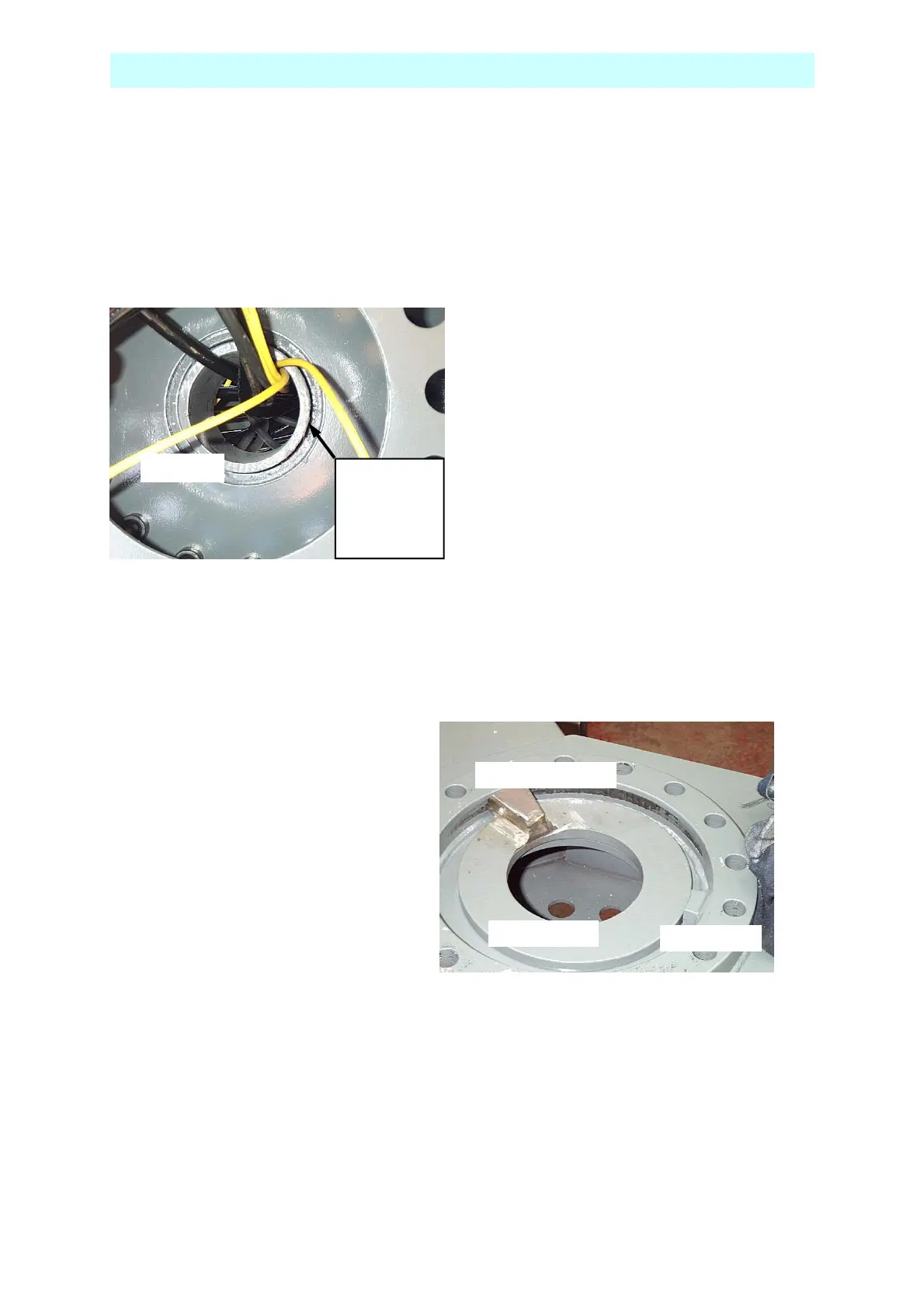

The critical parts of the slew stop are as follows :

Chassis stop

Slew stop ring

Slew stop ring tab

Slew tube stop

When slewing (rotating) the Slew tube stop will pick up on the Slew stop ring tab and drag it

around until Slew stop ring tab hits the Chassis stop. Now you will not be able to slew any

further - You can now slew almost two turns in the opposite direction until the Slew stop

ring tab hits the Chassis stop again. This gives you almost two turns “lock to lock”. From

the parking position this equates to “one turn left or one turn right” measured from the park-

ing position

Chassis stop

Slew stop ring

Slew stop ring tab

Spray LPS-3 in

between the

tube and the

chassis plate

Slew tube

MAINTENANCE PROCEDURE

Loading...

Loading...