page 21 of 27

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. 25/11/2013 // 999281

➨ Fill the hose to the vacuum sensor with disinfectant soluti-

on.

➨ Emptythehoseaftertheexposuretime.

Decontaminate all disassembled parts and the used tools in an

appropriate disinfectant solution or by autoclaving.

Comply with exposure time.

Prior to reassembling let the parts dry completely.

If the device is send for repair disassembled, ensure that all parts are packed

safely.

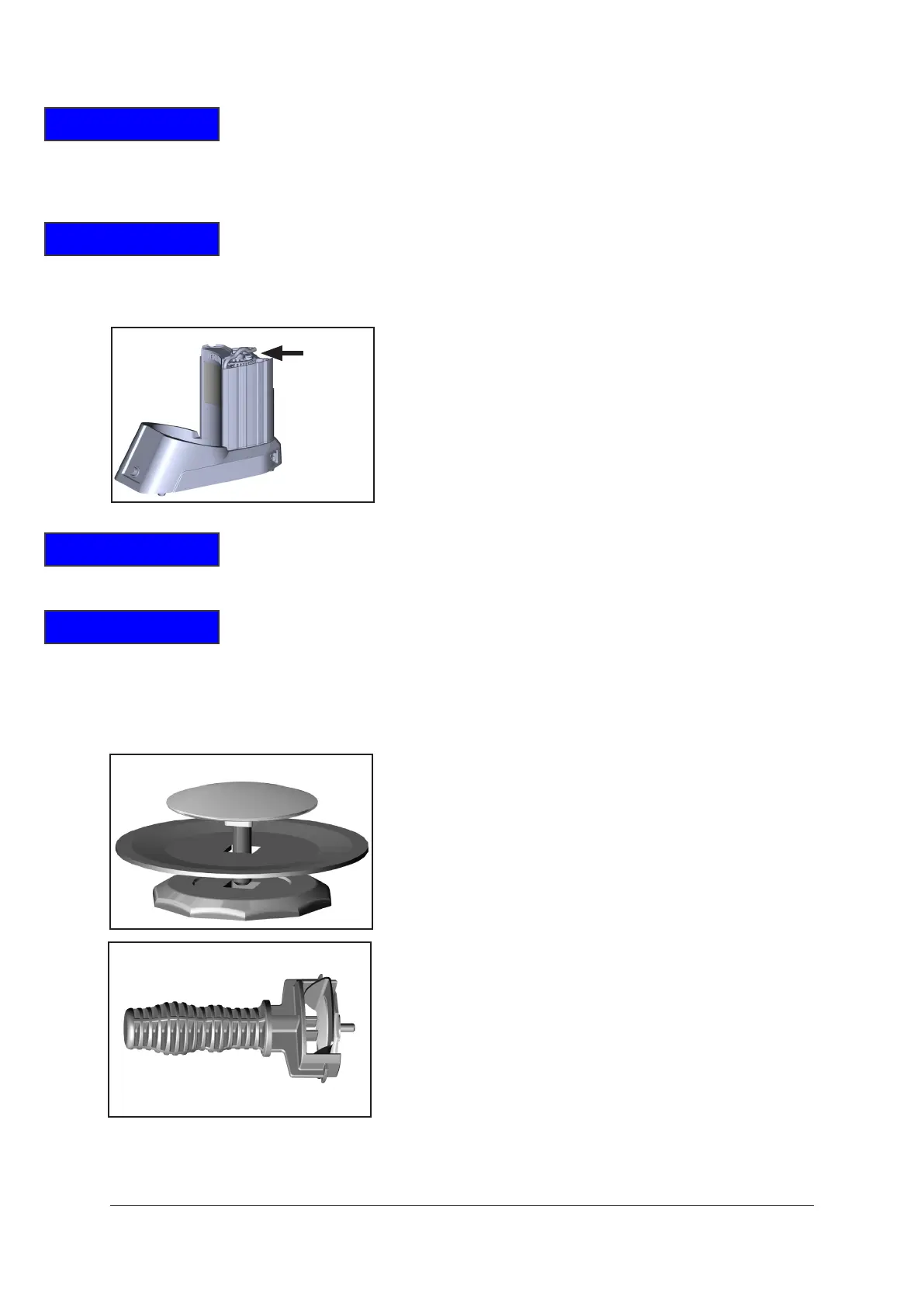

➨ Lift the diaphragm at the side. Place the diaphragm care-Lift the diaphragm at the side. Place the diaphragm care-

fully together with diaphragm clamping disc and diaphragm

support disc in the diaphragm key.

+ Avoiddamageofthediaphragm:Donotexcessivelybend

or crease the diaphragm.

➨ Assemble the original number of washers between dia-

phragm support disc and connecting rod.

+ Too few washers: The pump will not attain vacuum spe-

cication. Too many washers: Diaphragm clamping disc

will hit head cover, causing noisy operation and possibly

causing the pump to seize up.

➨ Position diaphragm between diaphragm clamping disc

withsquareheadscrewanddiaphragmsupportdisc.

+ Note: Position diaphragm with pale side towards dia-

phragmclampingdisc(facingpumpchamber).

+ Makesurethatthesquareheadscrewofthediaphragm

clamping disc is correctly seated in the guide hole of the

diaphragm support disc.

Reassembling

Priortodecontaminationcleansurfaceswithadampclothifnecessary.Usewateror

a mild detergent as cleaning agent.

NOTICE

NOTICE

NOTICE

NOTICE

Loading...

Loading...