page 22 of 27

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. 25/11/2013 // 999281

+ Position any washers that are present between diaphragm

support disc and connection rod.

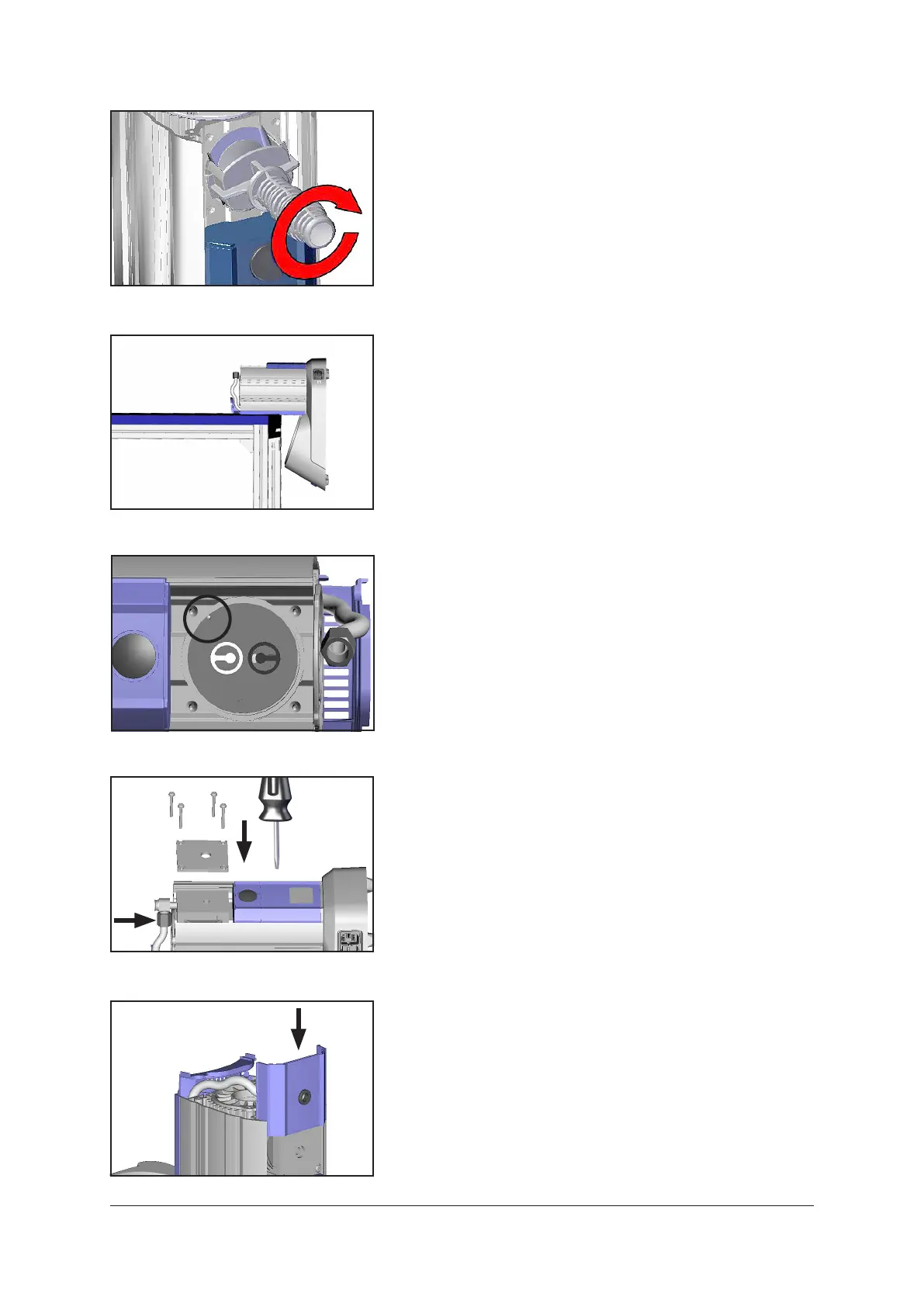

➨ Screw diaphragm clamping disc, diaphragm, diaphragm

support disc, and washers to connecting rod.

➨ Bring the diaphragm into a position in which it is in con-

tact with the housing and centered with respect to the bore

so that it will become clamped uniformly between housing

and head cover.

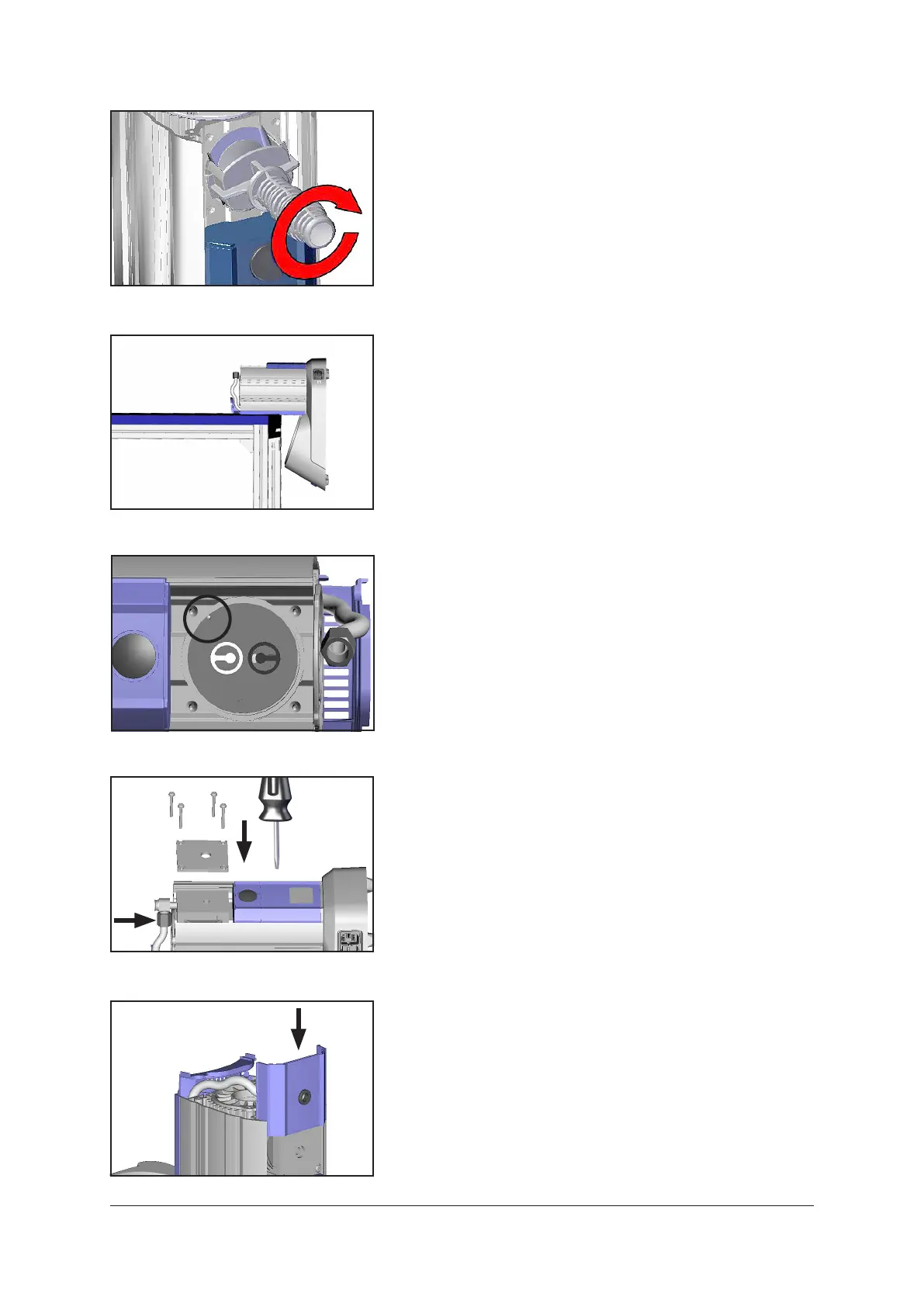

➨ Assemble head cover and valves.

+ Pay attention to the correct position of the guidance pin in

theheadcover(circleingure)!

+ Pay attention to correct orientation of the valves(see

gure):

Inlet sideofpumphead(blackvalve):Thevalvetongue

pointsatthekidney-shapedoriceinthevalveseat.

Outlet sideofpumphead(whitevalve):Thevalveisori-

ented the opposite direction as the valve at the inlet side.

Roundoriceunderthevalvetongue.

➨ LaydowntheBVConthesideofthepump,e.g.,atthe

edge of a workbench; support if necessary.

➨ Put on housing cover and housing cover insert.

+ Movehousingcoverinsertslightlytoensurethatthehead

covers are correctly positioned.

➨ Pay attention to washers and position screws. Screw in

4 screws with washers at the housing cover diagonally,

looselyatrstwithaTorxdriverT20,thentighten.

+ Do not tighten until head cover is in contact with housing,

maximumtorque:2.2ft

.

lb

f

(3Nm).

➨ Positionhosetoelbowttingandscrewontheunionnut.

➨ PositionBVCupright.

➨ Assemble the cover so that the groove in the in the face

side of the cover is at the inlet of the pump.

Loading...

Loading...