page 56 of 76

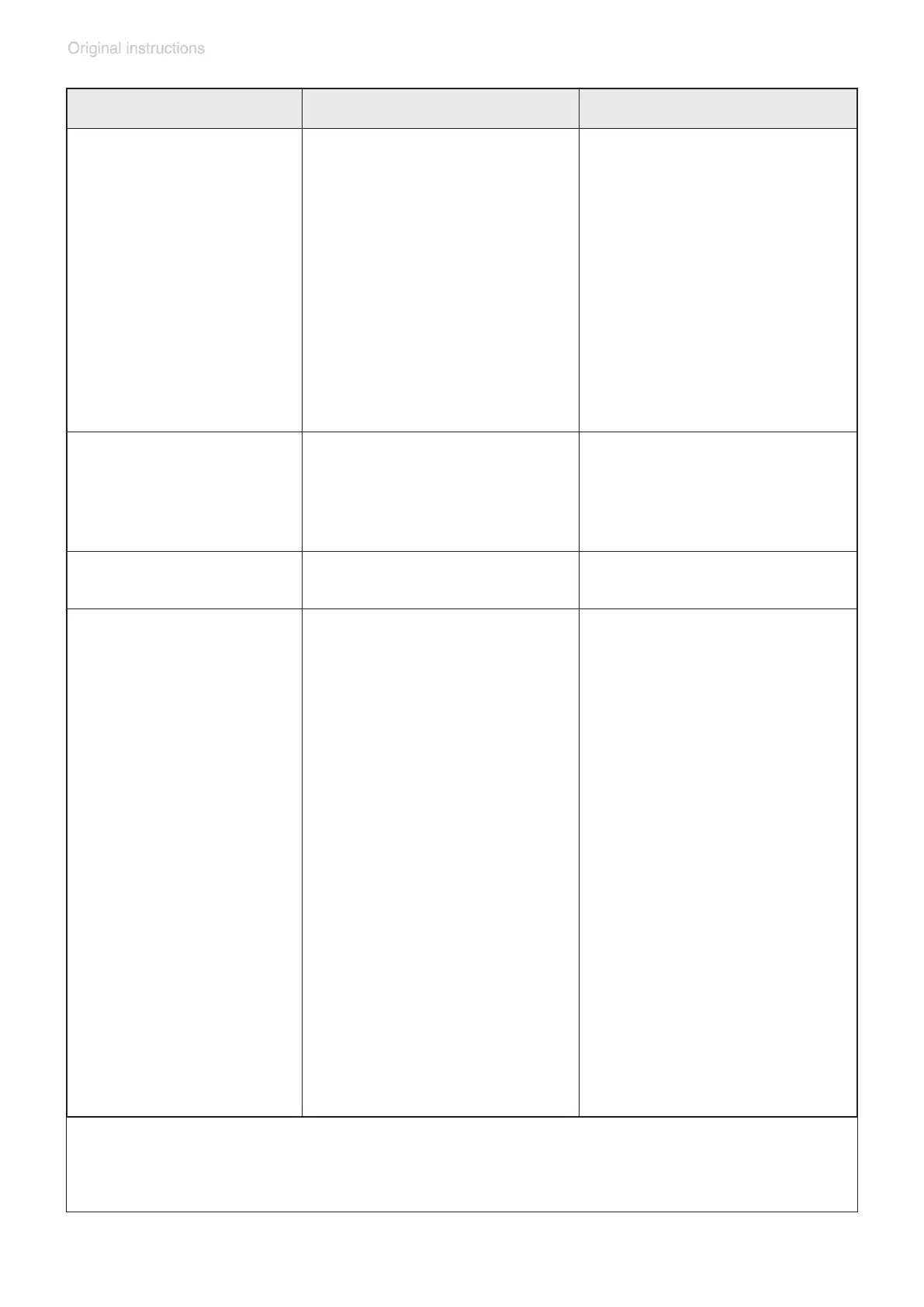

Fault Possible cause Remedy

❑

Pump is running

continuously.

➨

Leak in the system?

✔

Check tubing, seals,

coupling, and blind cap.

Screw in or replace if

necessary.

➨

Too high underpressure

for altitude / weather

conditions?

Vapor pressure of the

media inside the collec-

tion bottle too high?

✔

Reduce underpressure /

aspiration power.

➨

Other causes?

✔

Contact your local

distributor.

❑

Pump is running

continuously, all

LED´s indicating the

suction power are

ashing.

➨

Pressure sensor defec-

tive?

✔

Reduce suction power

using key “-”. If the error

persists, contact your lo-

cal distributor.

❑

Keys do not react.

➨

Keys of the touch panel

touched long-lasting?

✔

Wait 20 seconds and try

again.

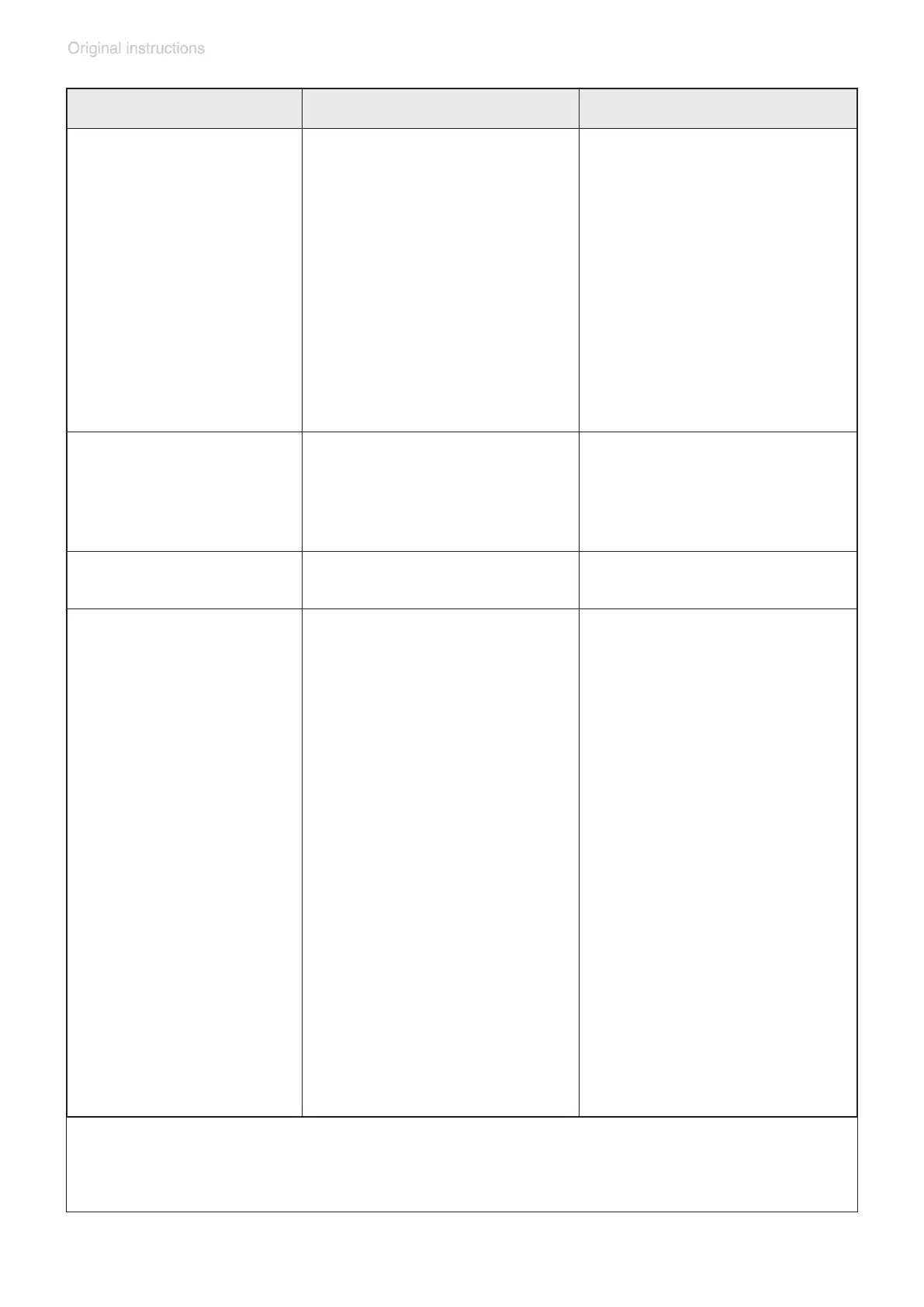

❑

Only BVC profes-

sional / G: Level

sensor gives a false

alarm or level alarm

occurs too early, too

late or not at all.

➨

Bottle has been re-

placed or changed am-

bient conditions?

✔

Adjust the level sensor.

➨

Not using original

VACUUBRAND BVC

bottle?

✔

Use original

VACUUBRAND BVC

bottle or original spare

bottle.

➨

Adhesive foil at the col-

lection bottle or the level

sensor foil?

✔

Remove adhesive foil.

➨

Bottle wet (after clean-

ing or disinfection)?

✔

Dry bottle. Adjust the

level sensor.

➨

Bottle inside and/or

outside with conductive

coating (e.g., silver con-

taining disinfectants)?

✔

Clean bottle carefully

and dry, see section

“Cleaning”. Adjust the

level sensor.

➨

Bottle inside and/or

outside with deposits /

incrustations?

✔

Clean bottle carefully

and dry, see section

“Cleaning”. Adjust the

level sensor.

Loading...

Loading...