12

Model Code Page

12. Repairs

8. 11. 1990

6000--8750 120 2

Handling of he avy components

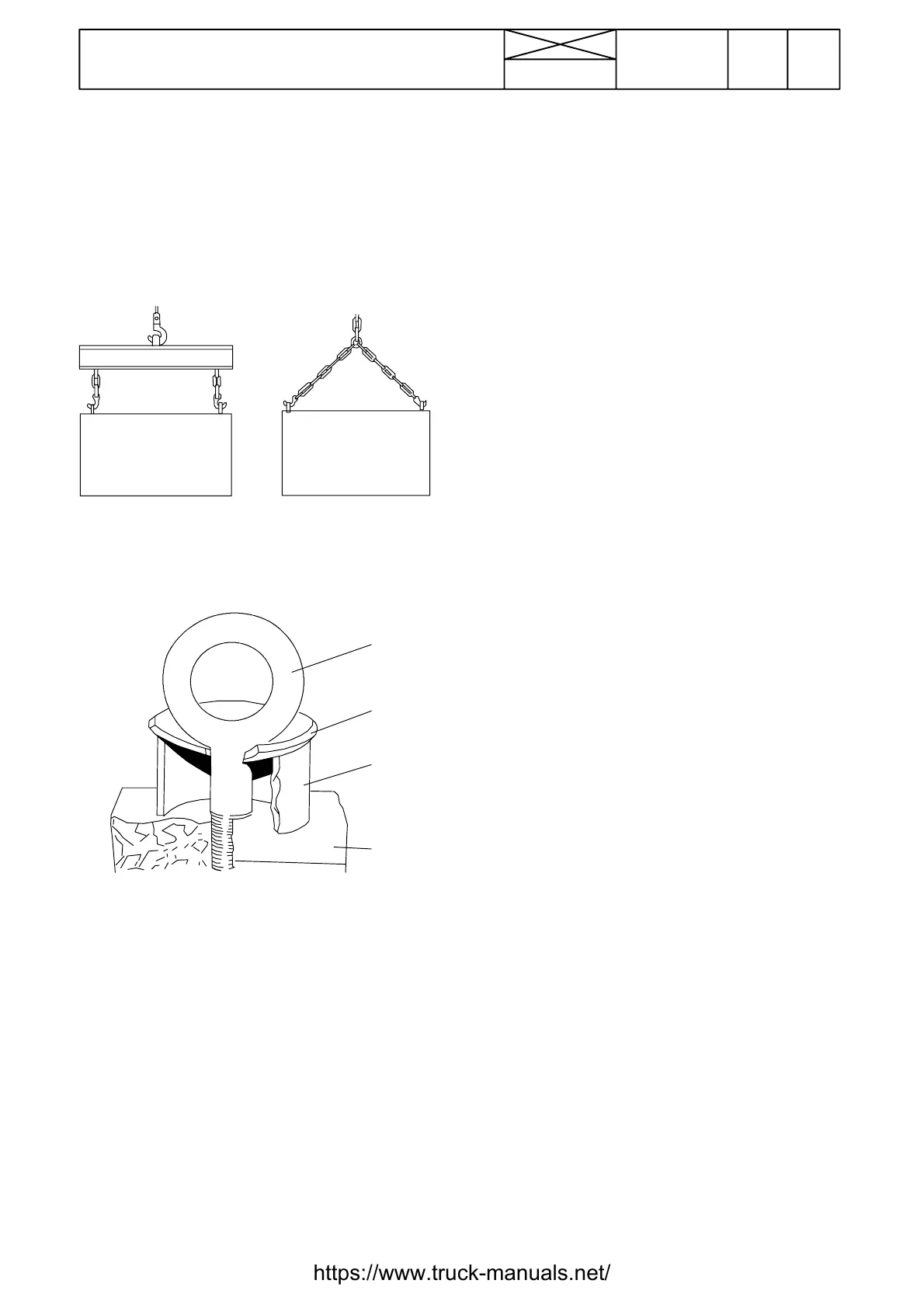

Unless otherwise specified, all removals should be accom-

plished using adjustable lifting equipment. All supporting

slings must be parallel to each other and as near vertical as

possible in relation to the object being lifted. However, where

slings are of a far greater capacity than the weight of t he load

to be fitted, a triangular lifting arrangement may be used.

Oikein

Rätt

Right

Richtig

Giusto

Väärin

Fel

Wrong

Falsch

Sbagliato

Correct

Teisingai

Mauvais

Netei-

singai

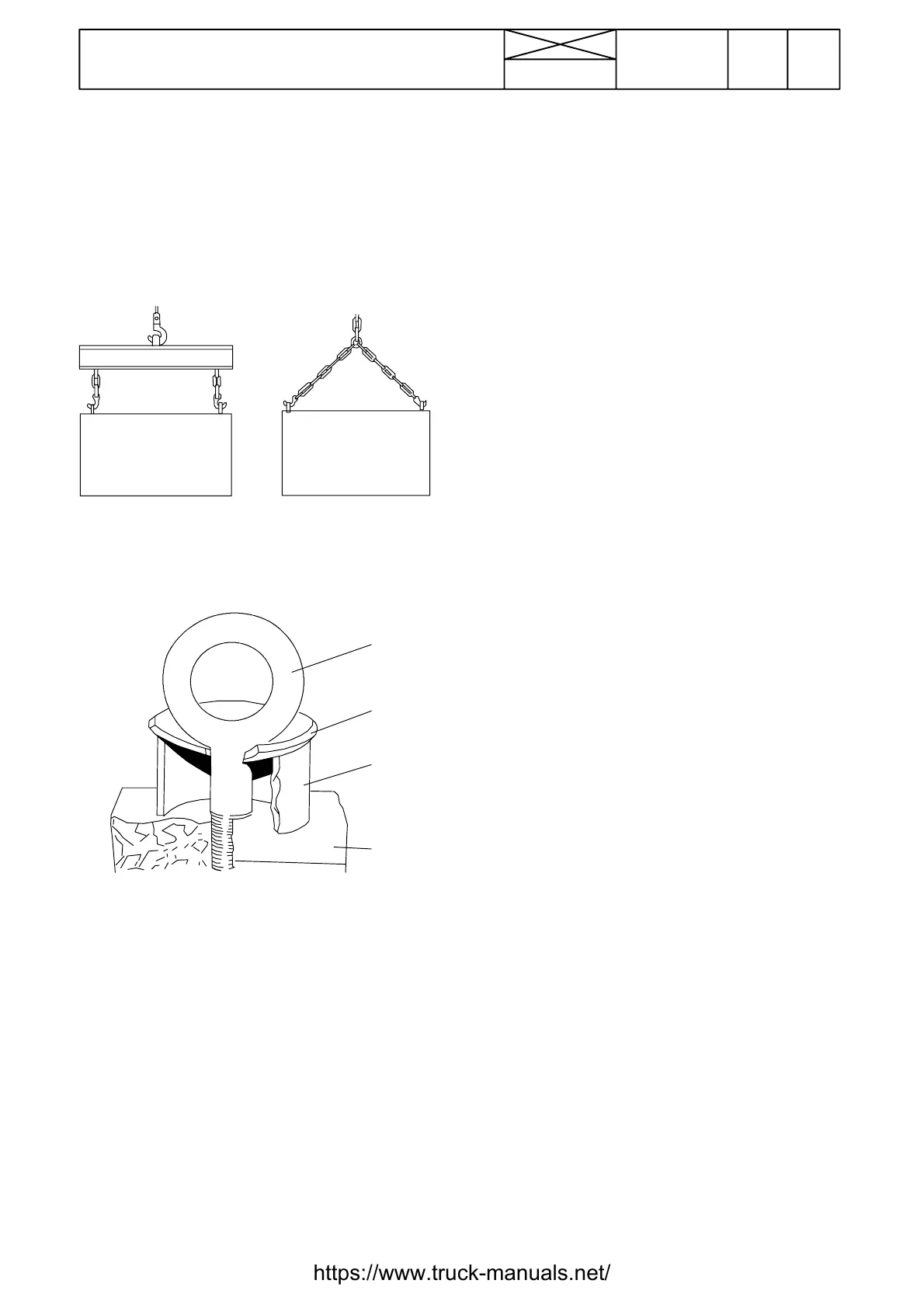

When removing a component at an angle, remember that the

capacity of an eyeboltis reduced when the angle between the

supporting members and the object becomes less than 90˚.

B

C

D

A

Forged eyebolt support

A. Load

B. Lifting shackle

C. Shackle retaining plate ( 3 mm thick)

D. Sleeve

When necessary the forged eyebolt can be supported in the

way shown in figure above. Sleeve D may or may not be

welded to plate.

Warning! If a part resists removal, check that allnuts and bolts

have been removed and that there is no interferenc e from ad-

jacent parts.

Cleanliness

To ensure long life of a machine, it is important tokeep dirt and

foreign material out of its vital working components. Precau-

tions must be taken to safeguard against this. Enclosed com-

partments, seals and filters have been provided to keep the

supply of air, fuel and lubricant clean. These protective de-

vices must not be removed.

Whenever hydraulic, fuel, lubricating oil or lines are discon-

nected, clean the point of disconnection and the surrounding

area. As s oon as a line has been disconnected, cap, plug or

tape the line or opening to prevent the ingress of foreign ma-

terial.

The same cleaning and covering precautionsshouldbe taken

when access co vers or inspection plates are removed.

Clean and inspect all parts. Make sure that all passages and

holes are clear. Cover all parts to keep them clean. Make sure

parts are clean when they are reassembled. Leave new parts

in their wrapping until they are actuallyneeded for reassembly

Assembly

When reassembling a machine, complete each step in se-

quence. never partially assemble one part then start to as-

semble another. Make all recommended adjustments. Al -

ways check the job on completion to ensure that nothing has

been overlooked. Recheck the various adjustments before

putting the machine back into service.

Note! Before fitting new parts, remove rust preventative com-

pound from all machined surfaces (usually ”peel---off sub-

stances).

Lubrication

Where applicable, fill the compartments of repaired or re-

newed components with the quantity, type and grade of clean

lubricantrecommended in the routinemaintenance section of

the Operator’s Manual.

Shims

When shims are removed, tie them together and identify their

locat i on. Keep shims clean and take care not to bend them

before refitting them.

Gaskets

Make sure that the holes in gaskets line up with lubricating oil

passages in the mating parts. If gaskets have to be made, use

material of the correct type and thickness. Make sure that

holes are punched in the right places.

Incorrectly punched gaskets can cause serious damage.

Lip type rubber seals

Lubricate the lips of lip---type rubber seals with oil before fit-

ment. Do not use grease on seals, except for grease seals.

https://www.truck-manuals.net/

Loading...

Loading...