46

Model Code Page

21. Engine

1. 9. 1992

6000--8750

211 4

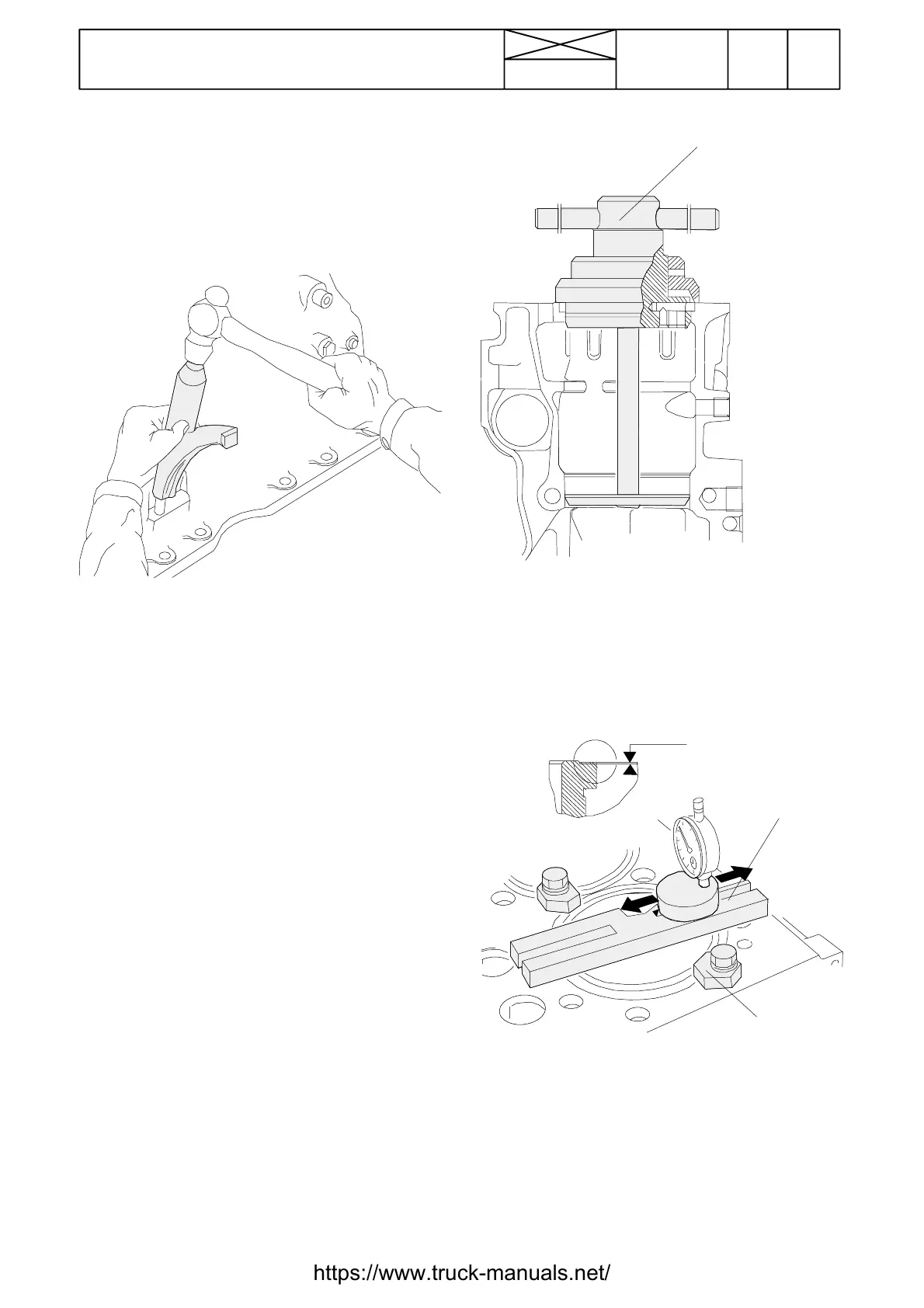

G. Fitting pipe for oil dipstick

1. Clean the seat for the pipe.

2. Apply locking fluid Loctite 601 to the lower end of the pipe.

3. Tap the pipe in to the correct fitting height with tool 9025

95900.

Note! The position of the pipe affectsan oil level in theengine.

H. Fitting cylinder line r

1. Clean the cylinder liner and its recess in the cylinder block.

Without o---rings the liner should rotate easily in it s recess .

2. Apply a thin layer of marking paint on the underside of the

cylinder liner flange. Fit the cylinder liner without o---rings and

turn it forwards and backwards. Lift out the liner and check

that paint has been deposited on the whole contact surface.

3. If the recess is damaged, or the cylinder liner height (see

point 5) needs to be adjusted, use milling cutter 9101 65600.

If necessary, a light lapping can be executed after milling with

the help of the cylinder liner. Apply lapping paste to the under-

side of the cylinder liner flange, and twist the liner with twisting

tool. Lapping is not suitable for adjusting the cylinder liner

height.

4. Clean the contact surfaces.

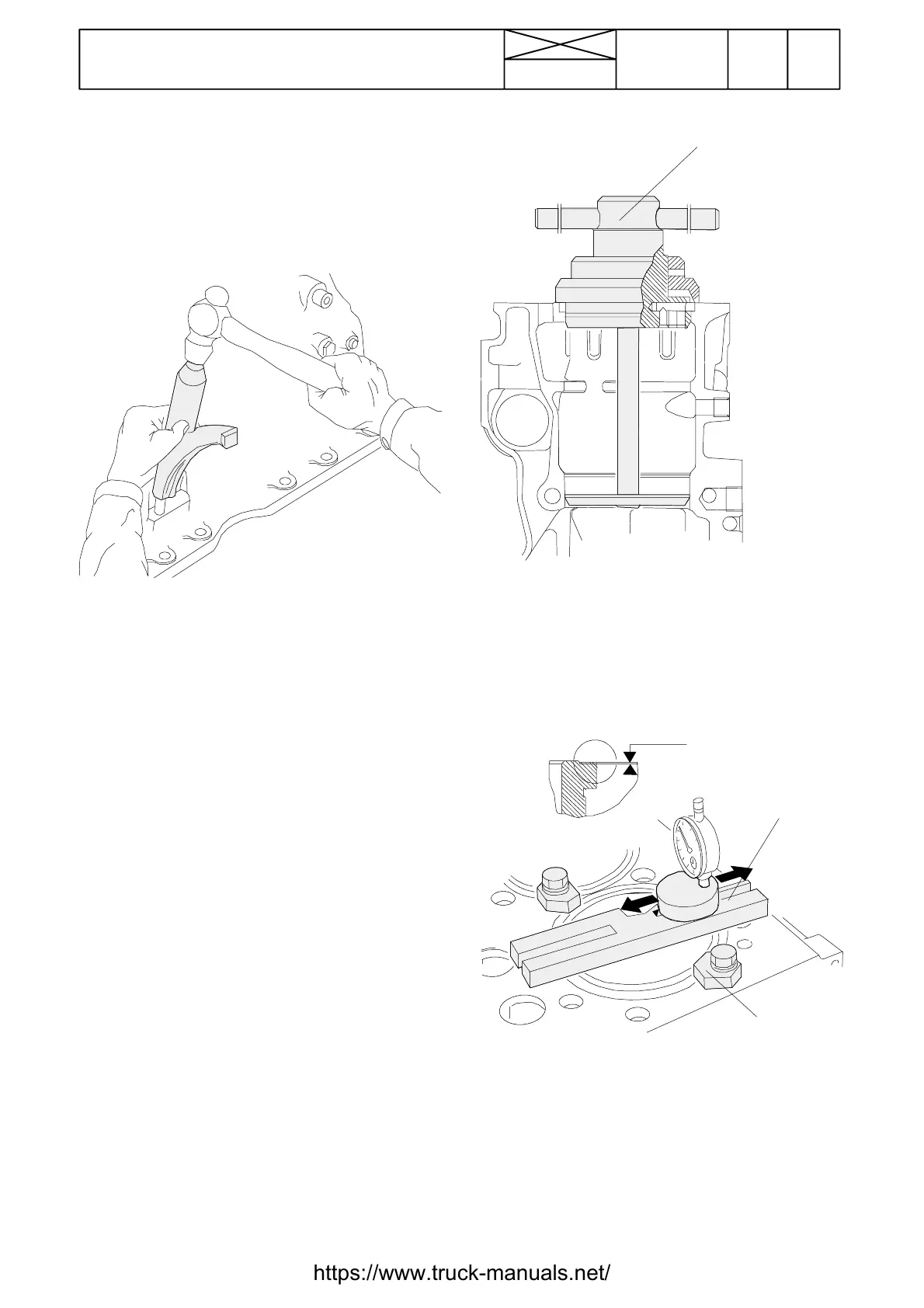

0,03---0,08 mm

9101 65600

9101 66300

9025 79200

5. Fit the cylinder liners and fix each liner with two press tools

910166300. Measure the cylinder liner height with a dial

gauge and holder 9025 79200. Zero the dial gauge against a

flat surface, for example, the cylinder block face. Measure

each liner in four places. The height of the liner above the cyl-

inder block face should be 0,03 ---0,08 mm. The height differ-

ence between cylinder liners under the same cylinder head

must not exceed 0,02 mm, nor must an intermediate cylinder

liner l ie lower than an outer o ne.

https://www.truck-manuals.net/

Loading...

Loading...