43

Model Code Page

21. Engine

1. 9. 1992

6000--8750 211 1

Repair instructions

Cylinder block and flywheel housing

(Op no 211)

1. Cylinde r block and c ylinde r liners

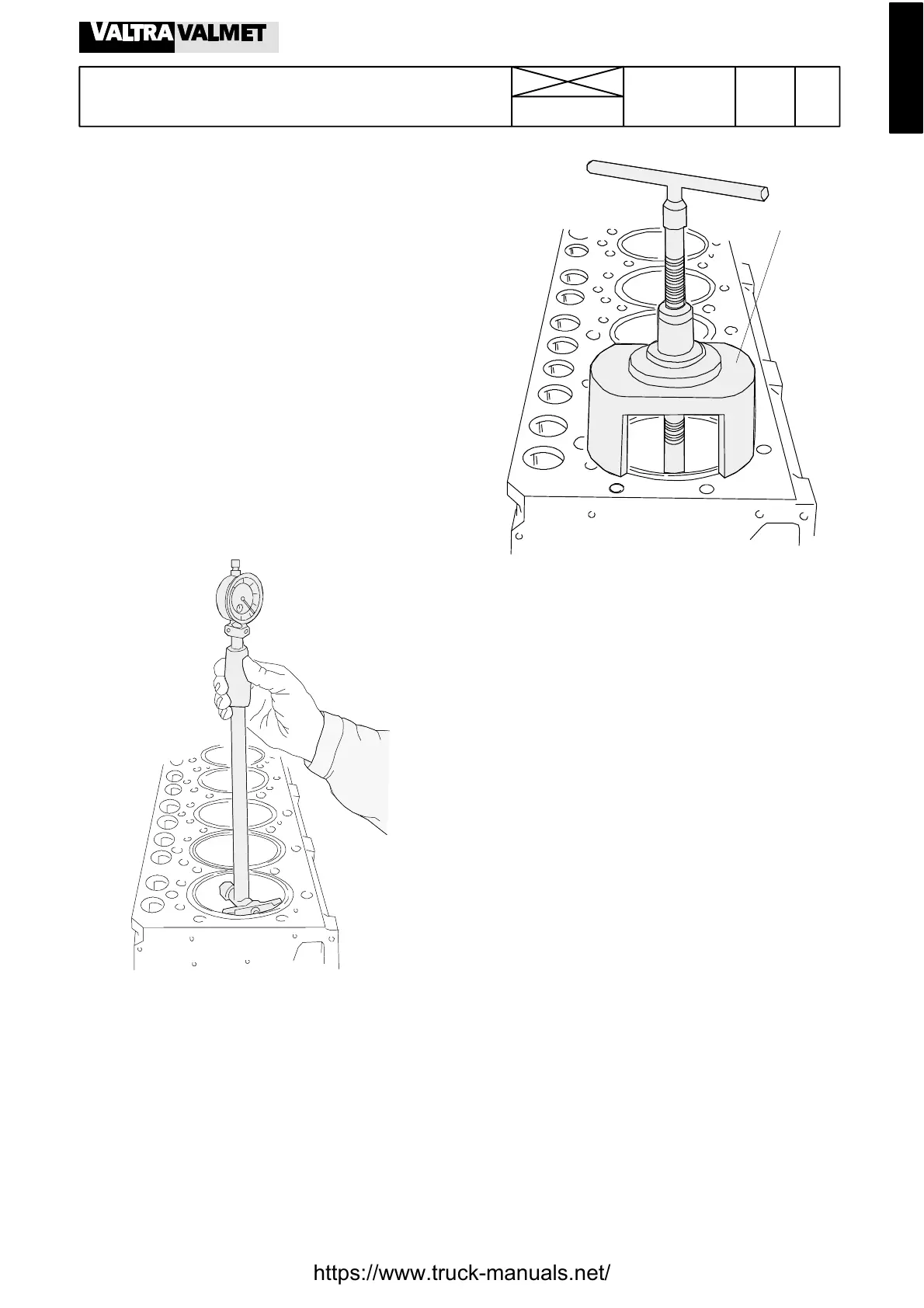

A. Measuring cylinder liner wear

Note! Cylinder liner wear can be measured when the engine

is attached to the tractor. Remove only the cylinder head and

crank the engine so that the piston is in the lower position.

1. Using a micrometer set the dial gauge to zero using a new

cylinder liner indicating the initial dimension of the bore:

108,00 mm.

2. Clean the inner surface of the cylinder liner thoroughly

before measurement.

3. Perform the measurement cros swise at the liner top end,

lower end and middle.

4. Check the gauge reading for maximum wear and ovalness

(compare with rating on page 210/4).

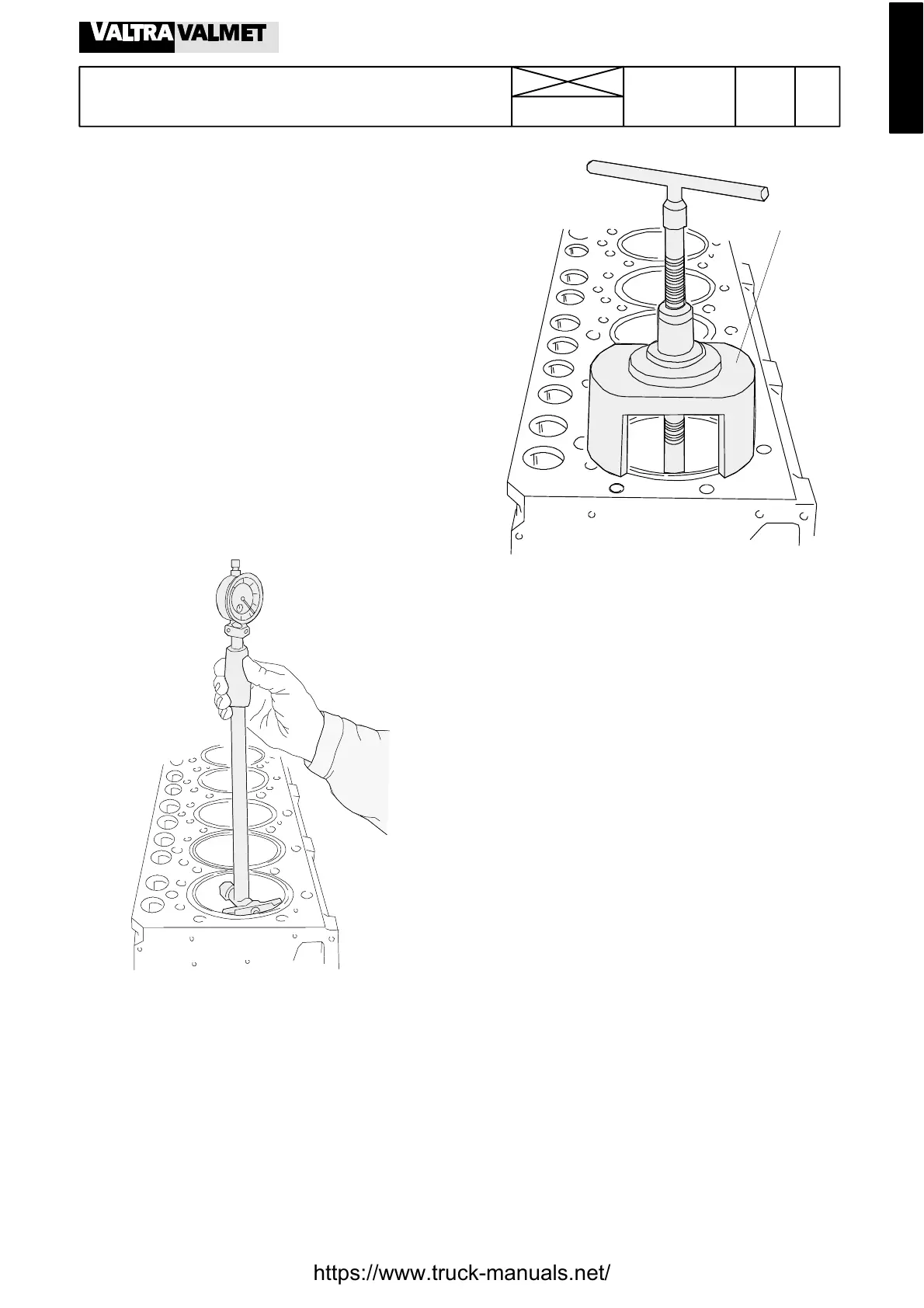

B. Removing cylinder liner

Note! See also page 219/1 for working order.

1. If the cylinder liners are to be used again they should be

marked so that they can be fitted in the same position.

2. Remove the cylinder liners using cylinder liner puller 9051

73100.

9051 73100

C. Checking cylinder block

1. Clean the cylinder block and all oilways.

2. Check the cooling channels and remove the scaleand sedi-

ment to ensure engine cool ing.

3. Check the tightness of the cup plugs and threaded plugs

in the cylinder block as well as the condition of the cylinder

block and sealing faces.

4. Measurethe wear of the camshaft bearing points (compare

with rating on page 210/4).

Note! If it is necessary to machine the upper face of the cylin-

der block, the pistons must be shortened by the same dimen-

sion. Observe the valve disc spaces on the piston upper face.

D. Changing camshaft bushing

1. Extract the bushing with an internal puller, for example

Sykes 854. If the camshaft rear end plug is removed the bush-

ing can be forced out with a long drift.

2. Clean the bushing location.

https://www.truck-manuals.net/

Loading...

Loading...