53

Model Code Page

21. Engine

1. 4. 1997

6000--8750

212 3

1. 9. 1992

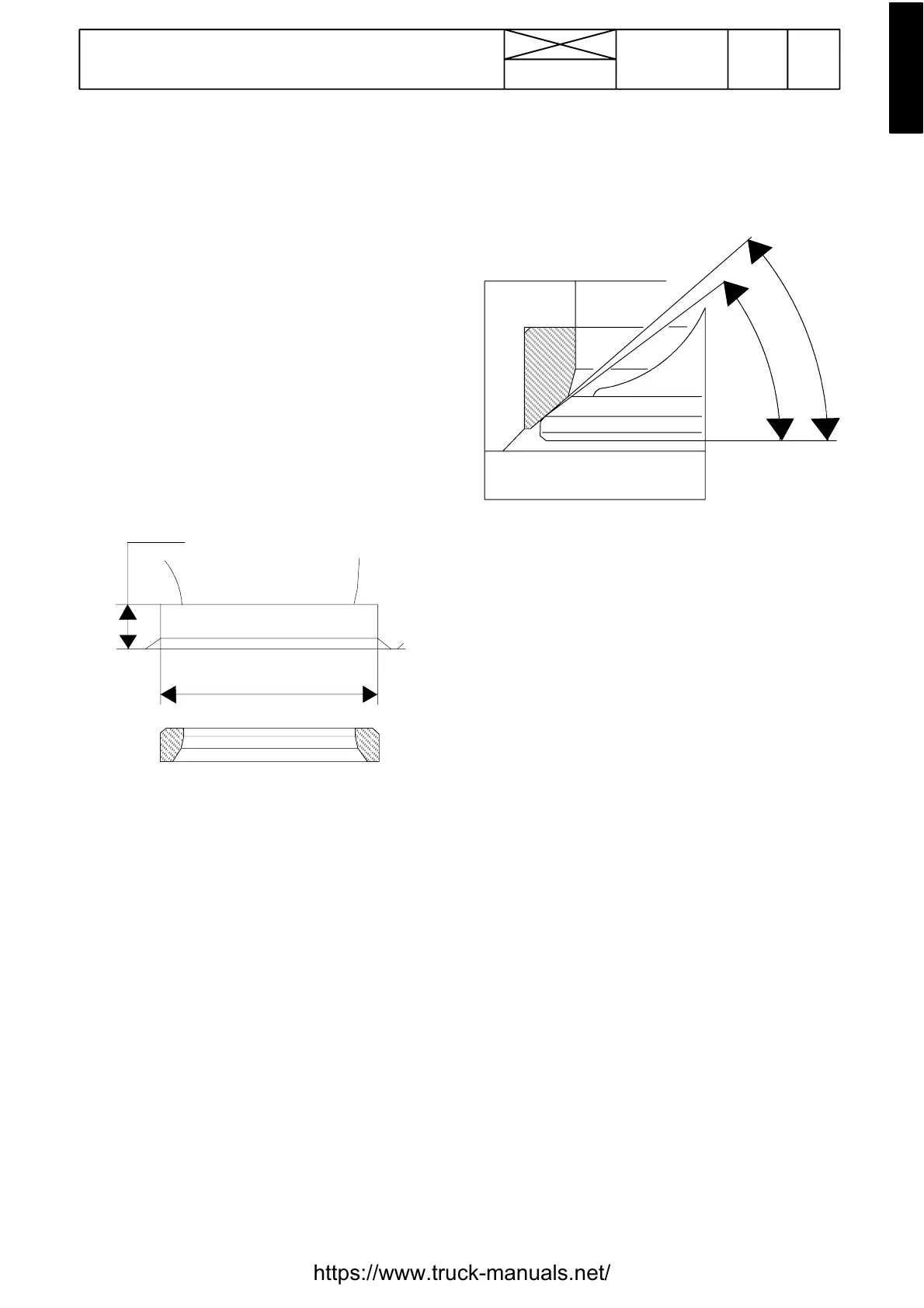

F. Changing valve seat inserts

Exhaust valves are fitted with separate valve seat inserts.If the

sealing surface is damaged so badly that itcannotberepaired

with machining, the seat inserts should be changed.

1.Grindthevalveheadonadiscardedvalvesothatitsits

down in the valve seat. Fit the valve and weld it in place in the

seat. Cool with water.

2.Turnthecylinderheadoverandknockoutthevalveand

seat.

3. Clean the valve seat location. Cool the new seat in liquid ni-

trogen until it stops bubbling, or alternatively place it in dry ice.

4. Fit the seat with a suitable drift. Machine the seat.

N.B. Where necessary, standard size seats can be replaced

by inserts with a larger outer diameter. See Specifications.

48,500...48,525

11

±0,1

The inlet valve seat machined direct on the cylinder head, can

be provided with a separate valve seat insert, order no 8366

47936. Machine the seat insert location on the cylinder head

(see figure above). Fit the insert like a seat of the exhaust

valve.

Note! Engines on tractors 8550 and 8750 have the valve seat

inserts also on the inlet valves. From March 96 these cylinder

heads have been marked with letter V, which is stamped on

the cylinder head front upper surface on the exhaust side. As

a spare part these heads can be fitted on all engines. The

V---marked cylinder heads are also availabl e for the 4---cylin-

der engines.

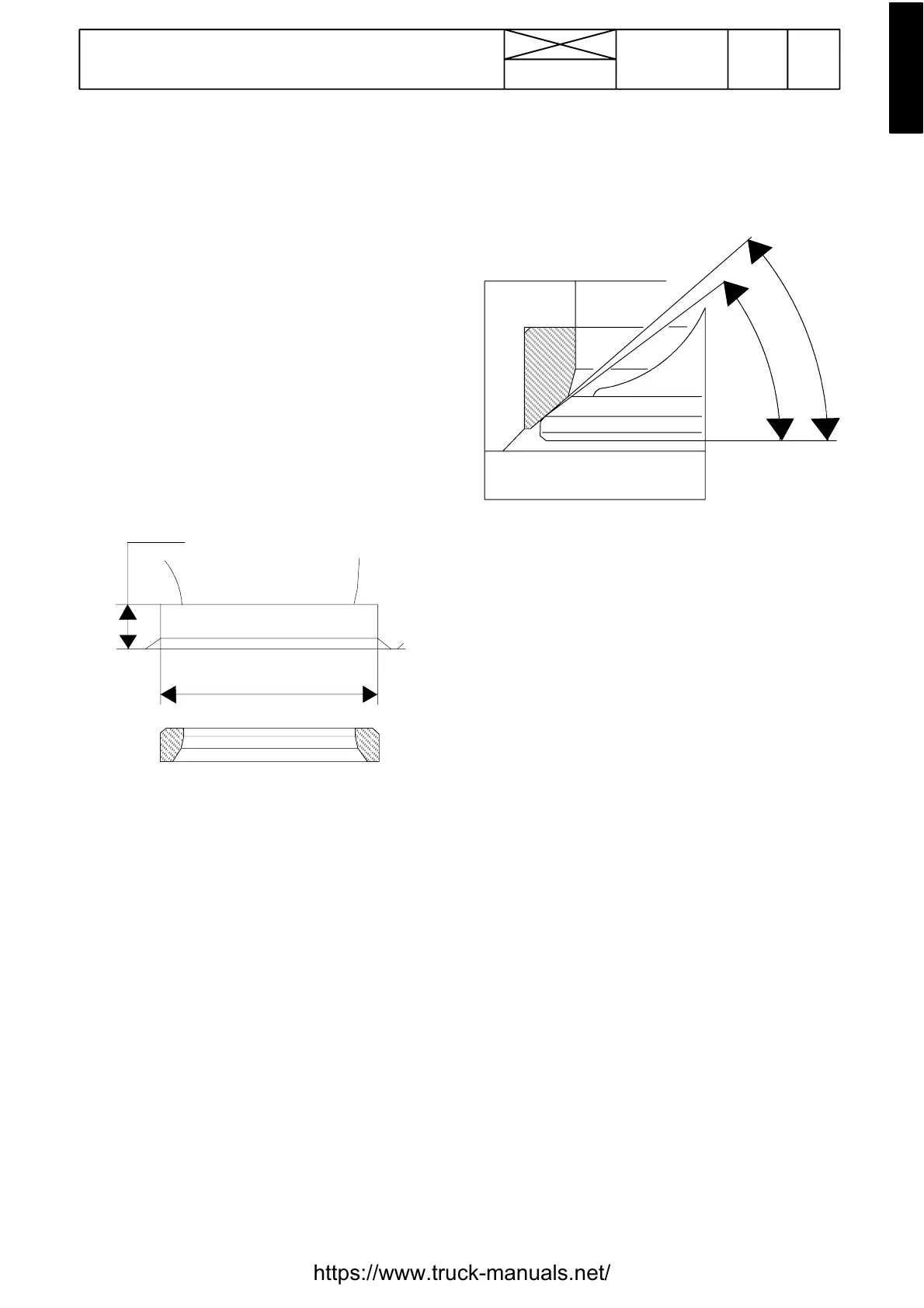

G. Grinding valves

In order to ensure that there is a proper seal around the valves,

there is a difference in the sealing surface angles. Thus there

is a very narrow sealing surface which seals effectively even

after prolonged running.

A

B

AB

INLET 35˚---20’ 35˚+20’

EXHAUST 45˚ ---20’ 45˚+20’

1.Grindthedamagedvalvediscwithavalverefacer.Adjust

angles to 45˚--- 2 0 ’ for exhaust valves and 35˚--- 2 0 ’ for inlet

valves.

2. Iftheedgeofthevalveheadislessthan1,5 mm after it has

been ground, or if the valve stem is bent, the valve should be

discarded.

3. If necessary, grind the end of the valve st em.

4. Lap the valves with lapping paste and check the contact

surface with marking paint.

5. Clean the cylinder head and valves of any remaining lap-

ping paste.

H. Fitting valves

1. Check the valve springs for straightness, length and ten-

sion using a spring tester. Compare with specifications.

2.Lubricatethevalvestemsandfitthevalvesinthecorrect

order in the cylinder.

3. Fit the springs, spring guides and valve keepers with the aid

of a lever for compressing valve springs, 9101 66200.

4. Tap the end of the valve stems lightly after fitting the valve

in order to ens ure that t hey are secure.

https://www.truck-manuals.net/

Loading...

Loading...