21

20

Operation

Welding technique

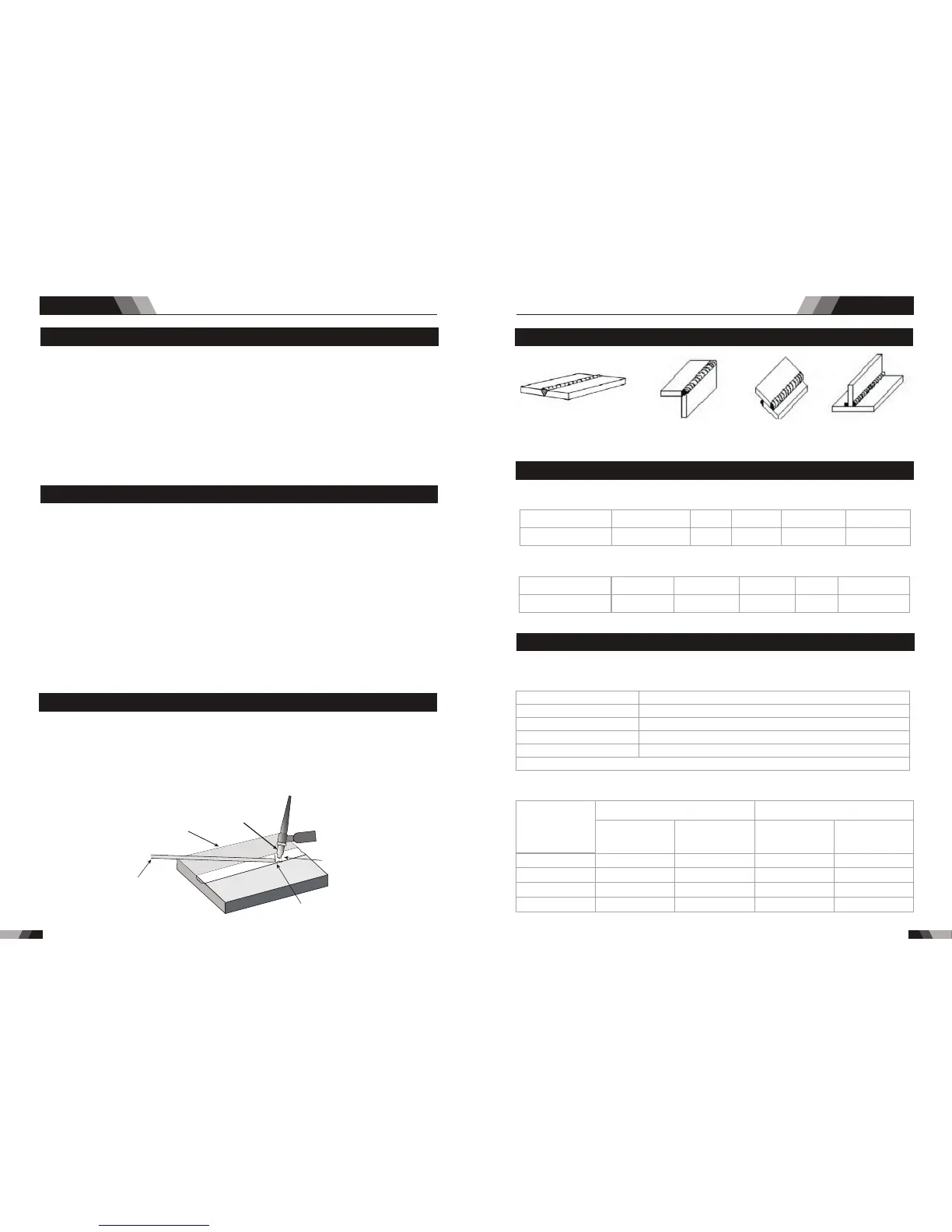

TIG Welding Application Shot

4.1 TIG Basic Welding Technique

Gas Tungsten Arc Welding (GTAW) or TIG (Tungsten Inert Gas) as it is commonly referred

to, is a welding process in which fusion is produced by an electric arc that is established

between a single tungsten (non- consumable) electrode and the work piece. Shielding is

obtained from a welding grade shielding gas or welding grade shielding gas mixture which

is generally Argon based. A filler metal may also be added manually in some circumstances

depending on the welding application.

Gas Cup

Either Ceramic,

High-lmpact or

Water Cooled

Metal

Work Piece

can Be Any Commercial

Metal

Welds Made With or

Without Addition

of Filler Metal

Inert Gas

Shields Electrode

and Weld Puddle

Tungsten Electrode

Non-Consumable

3.6 Operation Notices

◆Height above sea level is below 1000m.

◆Operation temperature range:-10˚C~+40˚C.

◆Relative humidity is below 90%(20˚C).

◆Preferably site the machine some angles above the floor level,the maximum

angle does not exceed 15˚.

◆The content of dust,acid,corrosive gas in the surrounding air or substance

can not exceed normal standard.

◆Take care that there is sufficient ventilation during welding.There is at least

30cm free disstance between the machine and wall.

3.5 Operation Environment

◆Read safty instruction and Chapter 1 carefully before attempting to use this

equipment.

◆Connect the ground wire the machine directly

◆In case closing the power switch, no-load voltage may be exported.Do not touch

the output electrode with any part of your body.

◆Before operation,no concerned people should be left,Do not watch the arc in

unprotected eyes.

◆Ensure good ventilation of the machine to improve duty ratio.

◆Turn off the engine when the operation finished to economize energy source.

◆When power switch shuts off protectively because of failure.Don’t restart it until

until problem is resolved.

Otherwise,the range of problem will be extended.

4.4 TIG Parameters Matching

The corresponding relationship between gas nozzle

diameter and electrode diameter

Gas nozzle diameter/mm

6.4

8

9.5

11.1

Electrode diameter/mm

0.5

1.0

1.6 or 2.4

3.2

Notice: the above parameters originate from <<Welding Dictionary>> P142,Volume 1 of Edition 2.

04

Gas nozzle and the shield gas flow rate

Welding

current range/A

DC positive connection

AC

Gas nozzle

diameter/mm

Gas flow

1

rate/L•min-

Gas nozzle

diameter/mm

Gas flow

1

rate/L•min-

10~100

101~150

151~200

201~300

4~9.5

4~9.5

6~13

8~13

4~5

4~7

6~8

8~9

8~9.5

9.5~11

11~13

13~16

6~8

7~10

7~10

8~15

Notice: the above parameters originate from <<Welding Dictionary>> P149,Volume 1 of Edition 2.

Protect effect

best better

good

bad

worst

Welding area color bright argent orange-yellow

blue-purple

caesious

white powder

of titanium oxid

The relation of welding area color & protect effect of Ti-alloy

4.3 The explanation of welding quality

The relation of welding area color & protect effect of stainless steel

Protect effect

best better

good

bad

worst

Welding area color argent,golden

blue

red-grey

grey

black

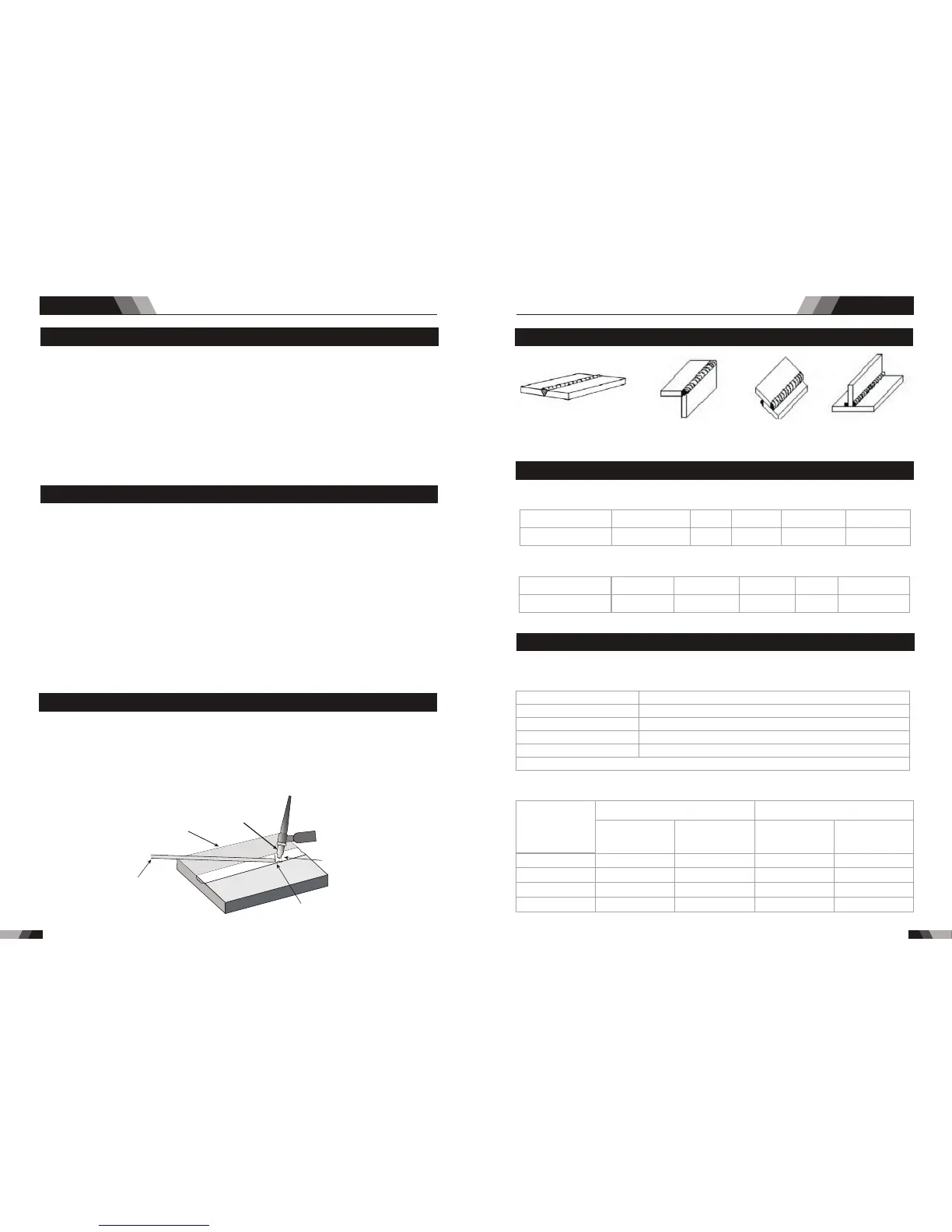

a butt joint b lap joint c coner joint d T joint

4.2 Joint froms in TIG

AC/DC WIG SERIES EQUIPMENTAC/DC WIG SERIES EQUIPMENT

Loading...

Loading...