23

22

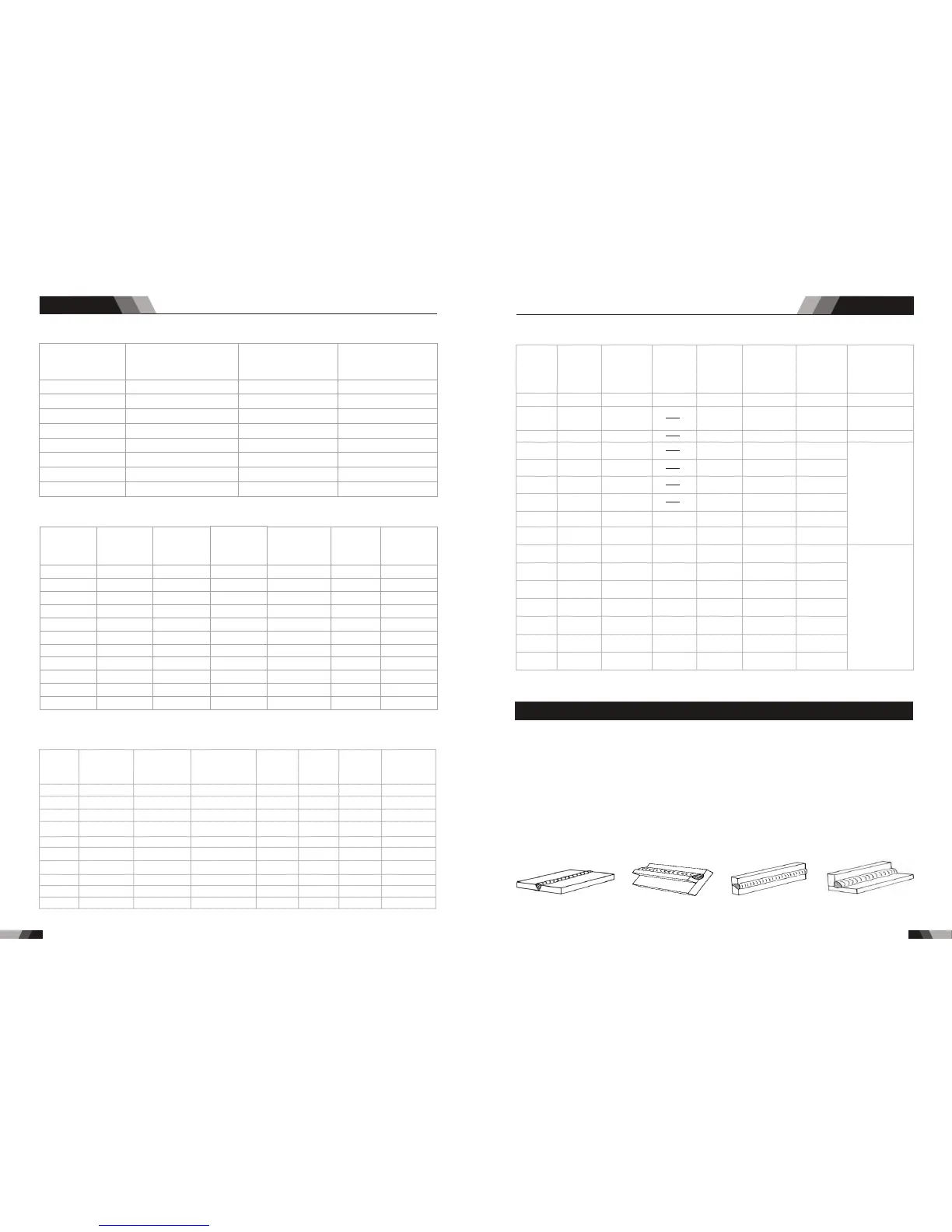

TIG of stainless steel(single run welding)

Workpiece

thickness

/mm

Joint form

tungsten

electrode

diameter

/mm

welding

wire

diameter

/mm

Argon gas

flow rate/

1

L•min-

welding

current

(DCEP)

Welding

speed/

cm•min-1

0.8

1.0

1.5

1.5

2.4

2.4

3.2

3.2

4.8

4.8

6.0

Butt joint

Butt joint

Butt joint

Corner joint

Butt joint

Corner joint

Butt joint

Corner joint

Butt joint

Corner joint

Butt joint

1.0

1.6

1.6

1.6

1.6

1.6

1.6

1.6

2.4

3.2

4.0

1.6

1.6

1.6

1.6

2.4

2.4

2.4

2.4

3.2

3.2

4.0

5

5

7

7

7

7

7

7

8

9

10-12

20~50

50~80

65~105

75~125

85~125

95~135

100~135

115~145

150~225

175~250

220~300

66

56

30

25

30

25

30

25

25

20

25

Notice: the above parameters originate from <<Welding Dictionary>> P150,Volume 1 of Edition 2.

Welding techniqueWelding technique

Tungsten

Electrode

Diameter/mm

Sharpened of

the Electrode

Diameter/mm

Angle of Cone(º)

Background

Current/a

1.0

1.0

1.6

1.6

2.4

2.4

3.2

4.0

0.125

0.25

0.5

0.8

0.8

1.1

1.1

1.5

12

20

25

30

35

45

60

90

2~15

5~30

8~50

10~70

12~90

15~150

20~200

20~300

Tungsten Electrode

Parameters of piping back sealing welding for mild steel(DCEP)

Piping

diameter

Φ/mm

Tungsten

electrode

diameter/mm

Gas nozzle

diameter/mm

Welding

wire diameter/mm

Welding current/A

Welding

current/A

Arc

voltage/V

Argon flow

1

rate/L•min-

Welding

1

rate/cm•min-

38

42

60

76

108

133

159

219

273

325

2.0

2.0

2.0

2.5

2.5

2.5

2.5

2.5

2.5

2.5

8

8

8

8~10

8~10

8~10

8~10

8~10

8~10

8~10

2

2

2

2.5

2.5

2.5

2.5.

2.5

2.5

2.5

75~90

75~95

75~100

80~105

90~110

90~115

95~120

100~ 120

110~ 125

120~ 140

11~13

11~13

11~13

14~16

14~16

14~16

14~16

14~16

14~16

14~16

6~8

6~8

7~9

8~10

9~11

10~12

11~13

12~14

12~14

12~14

4~5

4~5

4~5

4~5

5~6

5~6

5~6

5~6

5~6

5~6

Notice: the above parameters originate from <<Welding Dictionary>> P167, Volume 1 of Edition 2.

Notice: the above parameters originate from《Welding Dictionary》P538, Volume 2 of Edition 2.

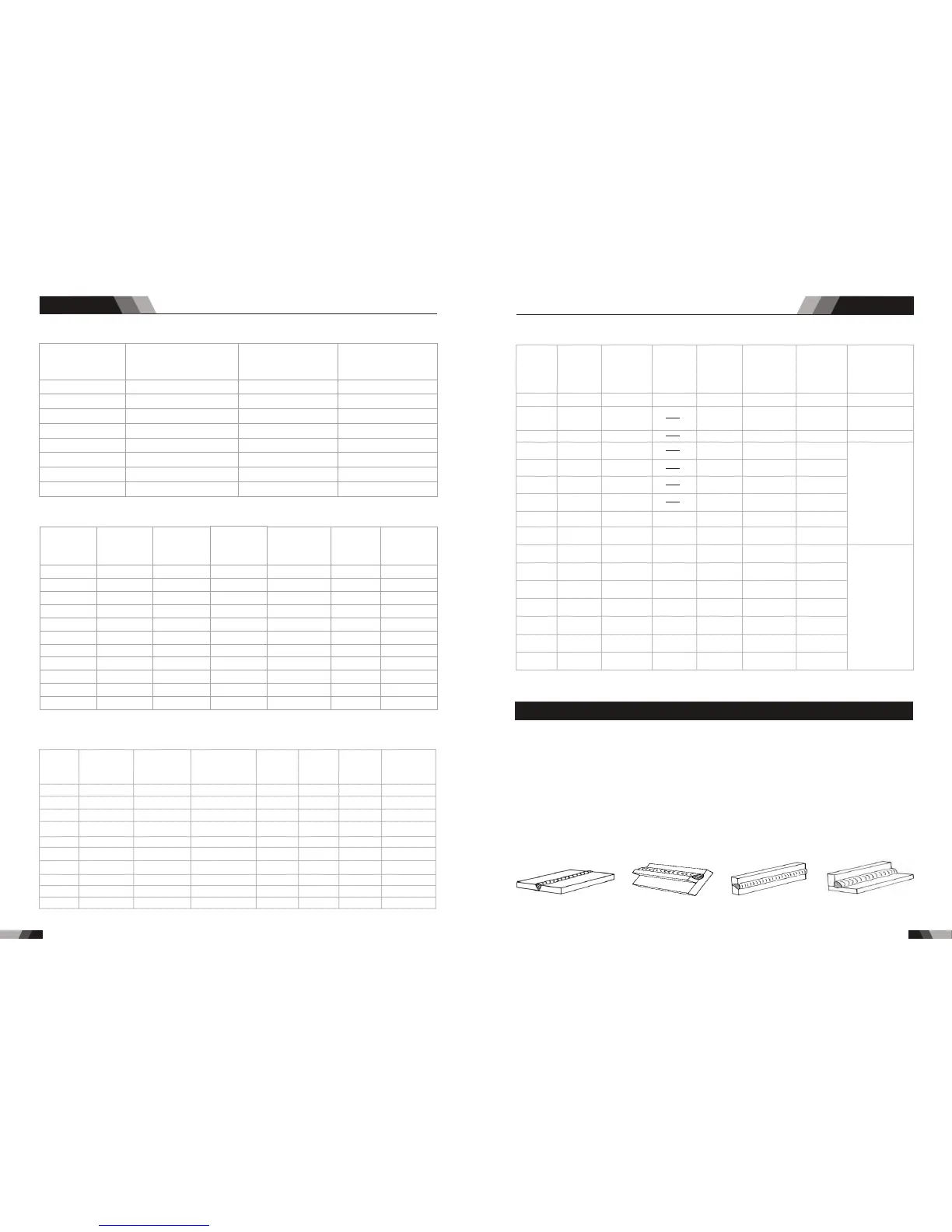

Parameters of AC TIG(MMA) for Aluinum and its alloy

Steet

thickness

/mm

Welding

wire

diameter

/mm

Tungsten

eletrode

diameter

/mm

Pre-heat

Temper

-ature/ºC

Welding

current/A

Argon flow

1

rate/L•min-

Gas nozzle

diameter

/mm

Remark

1.6

1.6~2.0

2~2.5

2~3

3

3~4

4

4~5

4~5

2

2

2~3

3

4

4

5

5

5

100

100~150

45~60

50~80

90~120

150~180

180~200

180~240

240~280

260~320

280~340

1

1.5

2

3

4

5

6

8

10

7~9

7~9

8~12

8~12

10~15

10~15

16~20

16~20

16~20

8

8

8~12

8~12

8~12

10~12

14~16

14~16

14~16

Flange welding

Flange or butt

welding by

one side

Butt welding

V-groove

butt welding

12

14

16

18

20

16~20

22~25

4~5

5~6

5~6

5~6

5~6

5~6

5~6

5~6

5~6

6

6

6

6

6~7

150~200

180~200

200~220

200~240

200~260

200~260

200~260

300~360

340~380

340~380

360~400

360~400

300~380

360~400

18~22

20~24

20~24

25~30

25~30

25~30

30~35

16~20

16~20

16~20

16~20

20~22

16~20

20~22

X-groove

butt welding

4.5 MMA Basic Welding Technique

Arc Welding Practice

The tec hniqu es used for a rc weldin g are almost identical regardless of what types of

metals are being joined. Naturally enough, different types of electrodes would be used

for different metals as described in the preceding section.

Welding Position

Th e elec tro de s de al t wi th in t his pu bli catio n ca n be used in mos t posi ti ons , i.e. th ey

are suitable for welding in flat, horizontal, vertical and overhead positions. Numerous

applica tions c all for welds to be made in po sitions intermedi ate betw een thes e. Some

of the common types of welds are shown

Flat Position,

Down Hand Butt Weld

Flat Position,

Gravity Fillet Weld

Horizontal Position,

Butt Weld

Horizontal- Vertical

( HV) Position

AC/DC WIG SERIES EQUIPMENTAC/DC WIG SERIES EQUIPMENT

Loading...

Loading...