0908

Summary

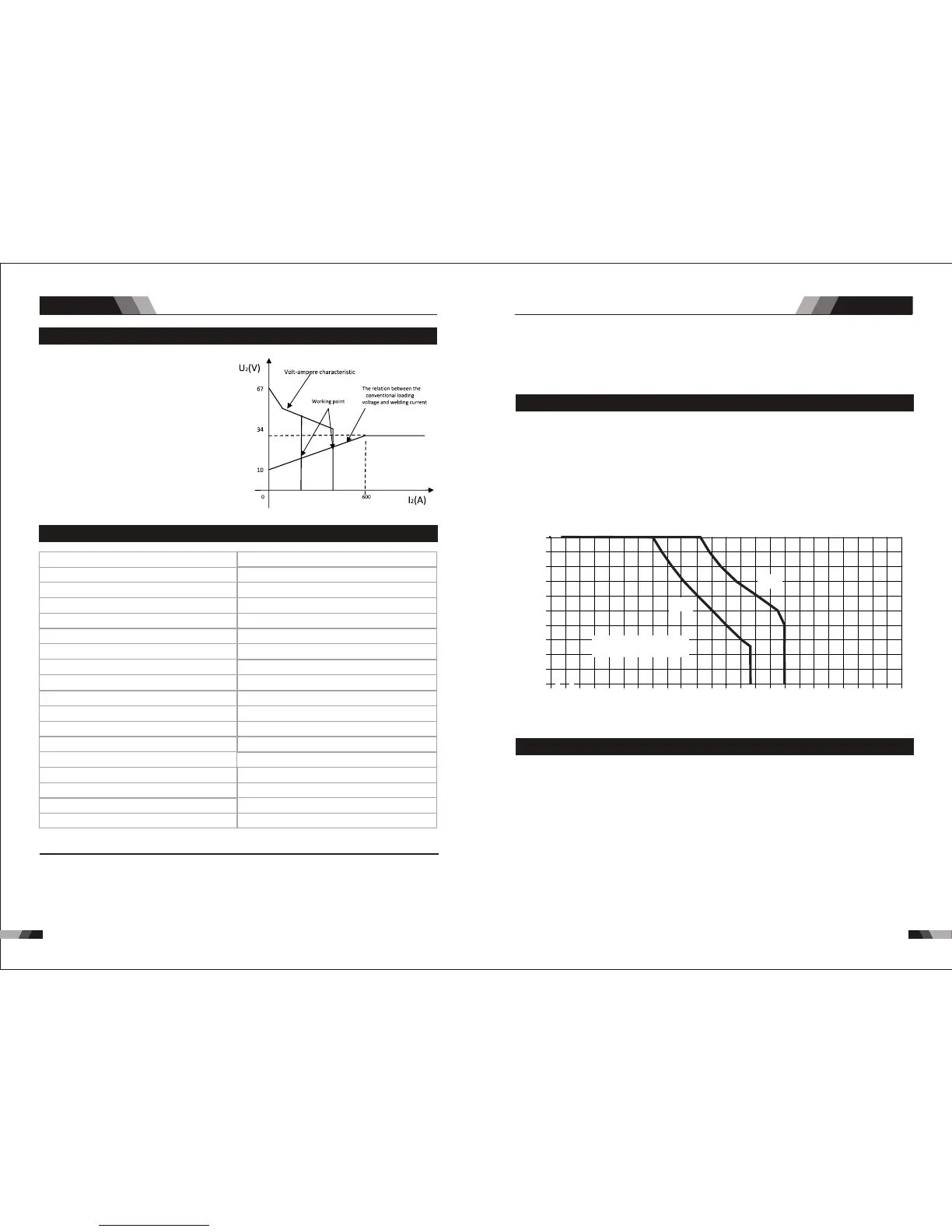

2.3 Volt- Ampere Characteristic

When I ≤600A, U =10+0.04I (V);

2 2 2

When I >600A,U =34(V).

2 2

TIG London2400 AC/ DC welding

machine has an excellent volt-ampere

characteristic, whose graph is shown

as the following figure. The relation

between the conventional rated loa-

ding voltage U and the conventional

2

welding current I is as follows:

2

2.4 Specifications

170A @ 25%, 26.8V / 85A @ 100%, 23.4V

200A @ 40%, 18V / 126A @ 100%, 15V

9.88 kg

10 - 170A

10 - 200A

15.4A

30.9A

10KVA

H360mmxW160mmxD380mm

Description

Weight

Power Source Dimensions

Cooling

Welder Type

European Standards

Number of Phases

Nominal Supply Voltage

Nominal Supply Frequency

Welding Current Range (MMA Mode)

Welding Current Range (TIG Mode)

Single Phase Generator Requirement

MMA Welding Output, 40ºC, 10 min.

TIG Welding Output, 40ºC, 10 min.

Open circuit voltage (MMA/TIG)

Protection Class

Maximum Input Current

Effective Input Current

SIWM DIGITAL London2400

Fan Cooled

EN 60974-1 / IEC 60974-1

1

230V +/- 15%

50/60Hz

60V DC

IP23

Inverter Power Source

Note 3: Motor start fuses or thermal circuit breakers are recommended for this application.

Check local requirements for your situation in this regard.

Note 1: The Effective Input Current should be used for the determination of cable size &

supply requirements.

Note 2: Generator Requirements at the Maximum Output Duty Cycle.

NOTE

Due to variations that can occur in manufactured products, claimed performance, voltages,

ratings, all capacities, measurements, dimensions and weights quoted are approximate

only. Achievable capacities and ratings in use and operation will depend upon correct

installation, use, applications, maintenance and service.

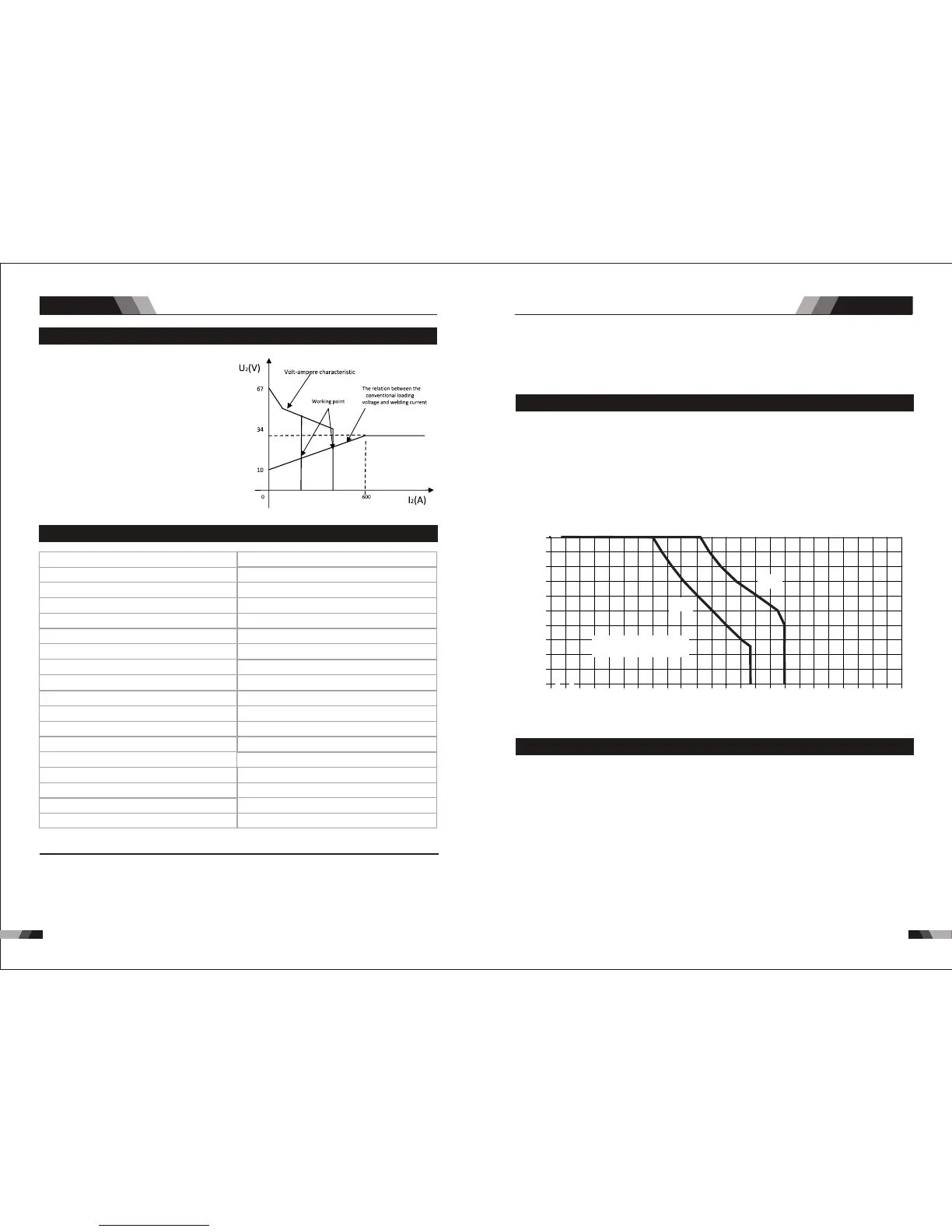

2.5 Duty Cycle

The rated duty cycle of a Welding Power Source, is a statement of the time it may be

operated at its rated welding current output without exceeding the temperature limits of

the i ns ul ation of the co mp on ent parts. To exp la in the 10 minute duty cycle p er io d the

following example is used. Suppose a Welding Power Source is designed to operate at

a 5 0% duty cycle, 200 am pe re s at 2 8 vol ts . This means that it has been designed and

built to provid e the rat ed amperag e (200A) for 5 minu te s, i.e. arc weldi ng time, out of

every 10 minute period (50% of 10 minutes is 5 minutes). During the other 5 minutes of

the 10 minute per iod th e We lding Pow er Source must i dle and b e a llowe d to cool . Th e

thermal cut out will operate if the duty cycle is exceeded.

Duty Cycle(PERCENTAGE)

Welding Current(AMPS)

◆2.5m Power cable

◆200 Amp Electrode Holder With 2.5m cable

◆200 Amp Earth Clamp With 2.5m cable

◆4m TIG Torch WP-17

◆4m TIG Torch WP-17

◆3m Gas Hose

◆Operating Manual

2.6 Packaged Items

2525

5050

7575

100100 1 25125 150150 175175

00

1 01 0

2 02 0

3 03 0

4 04 0

5 05 0

6 06 0

7 07 0

8 08 0

9 09 0

1 0 01 0 0

2 00 225 250 27527500

Safe Operating Region

(TIG&STICK)

300

MMA

TIG

Summary

AC/DC WIG SERIES EQUIPMENTAC/DC WIG SERIES EQUIPMENT

Loading...

Loading...