36

PHTM II

Installation, Operating & Service Instructions

110331-01 - 5/20

10 Heating System Piping (continued)

5. Automatic air vent (required)

A. Factory installed air vent is included on boiler

heat exchanger, to vent heat exchanger. A

system air vent is also required.

B. Manual air vents will usually be required in

other parts of the system to remove air during

initial fill.

6. Manual reset high limit (required by some codes

i.e. ASME CSD-1)

A. Install high limit in boiler supply piping just

above boiler with no intervening valves.

B. Set manual reset high limit to 200°F. Wire

limit to "external limit" terminal on low voltage

connection board per Section 13 Field Wiring.

7. Isolation valves are useful when boiler must be

drained, as they will eliminate having to drain and

refill entire system.

8. Strainer (recommended)

A. Install a Y strainer, or dirt/magnetic filter

strainer to prevent any system debris from

entering boiler and fouling of water passages.

B. Note that some strainers have a significant

pressure drop, which may impact ability of

system pump to obtain required flow.

9. Drain valve (required)

Install drain valve as shown in Figure 10-2.

10. Low water cut-off (LWCO) (may be required by

local jurisdiction)

A. Protection of this boiler against low water and/

or inadequate flow is provided by UL353

certified flow switch built into boiler.

B. This is a water tube boiler and this flow switch

is therefore only effective way to provide

such protection.

C. Section HG614(c) of 2015 ASME Boiler and

Pressure Vessel Code recognizes use of a

listed flow switch in lieu of LWCO on water

tube boilers.

D. In event a local jurisdiction insists upon

installation of LWCO with this boiler, refer

to Section 13 Field Wiring and LWCO

manufacturer's instructions for proper wiring.

• Auto reset LWCO: 105591-01

• Manual reset LWCO: 108182-01

E. Install LWCO in supply piping at point

prescribed by the local jurisdiction (generally

at a point above boiler, in common header

piping).

F. If probe type LWCO is used, be certain that it

is located at a point in piping from which air

can escape to an automatic air vent.

G. Generally, this means there should be no

down-turns in piping between LWCO

and point where automatic air vent is

installed.

H. Failure to do this may result in nuisance boiler

shut-down due to small amounts of air

trapped around probe.

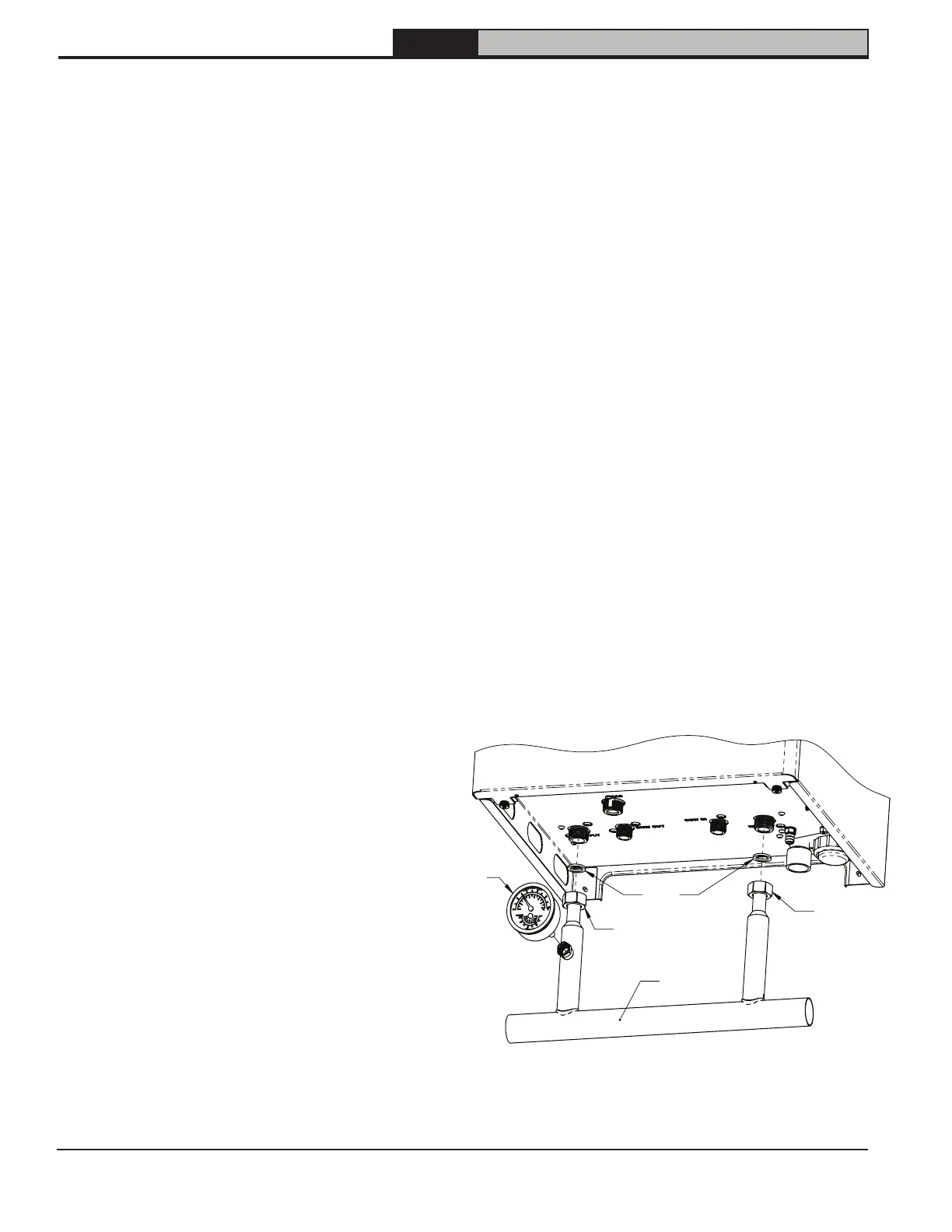

11. Low Loss Header (supplied with this boiler)

provides instant primary-secondary

connection.

Boiler Supply

Connection

(G 3/4")

Boiler Return

Connection

(G 3/4")

System

Return

(1-1/4" sweat)

System

Supply

(1-1/4" sweat)

Low Loss

Header

Gaskets

T/P

Gauge

(1/4" NPT)

Figure 10-1: Low Loss Header Connections

Loading...

Loading...