37110331-01 - 5/20

PHTM II

Installation, Operating & Service Instructions

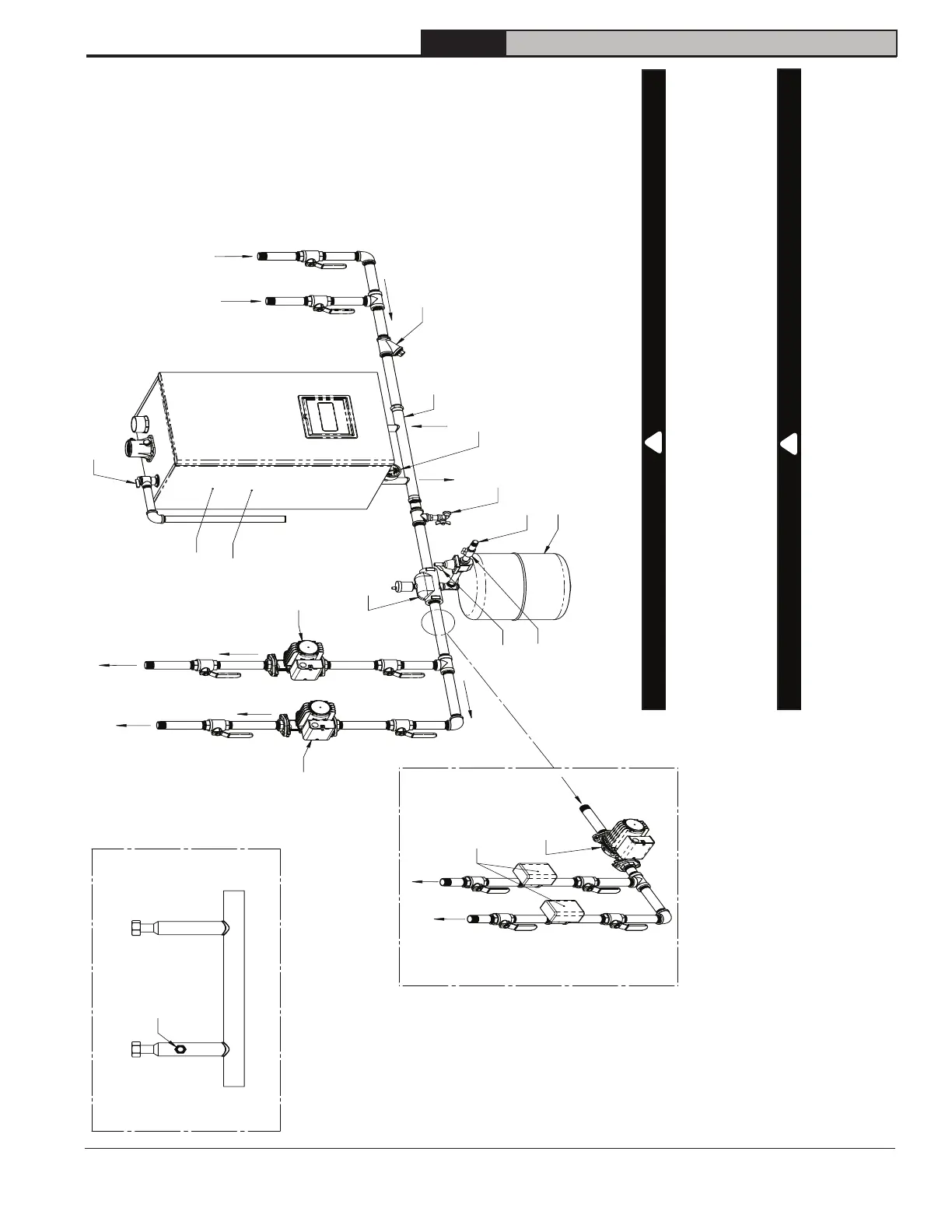

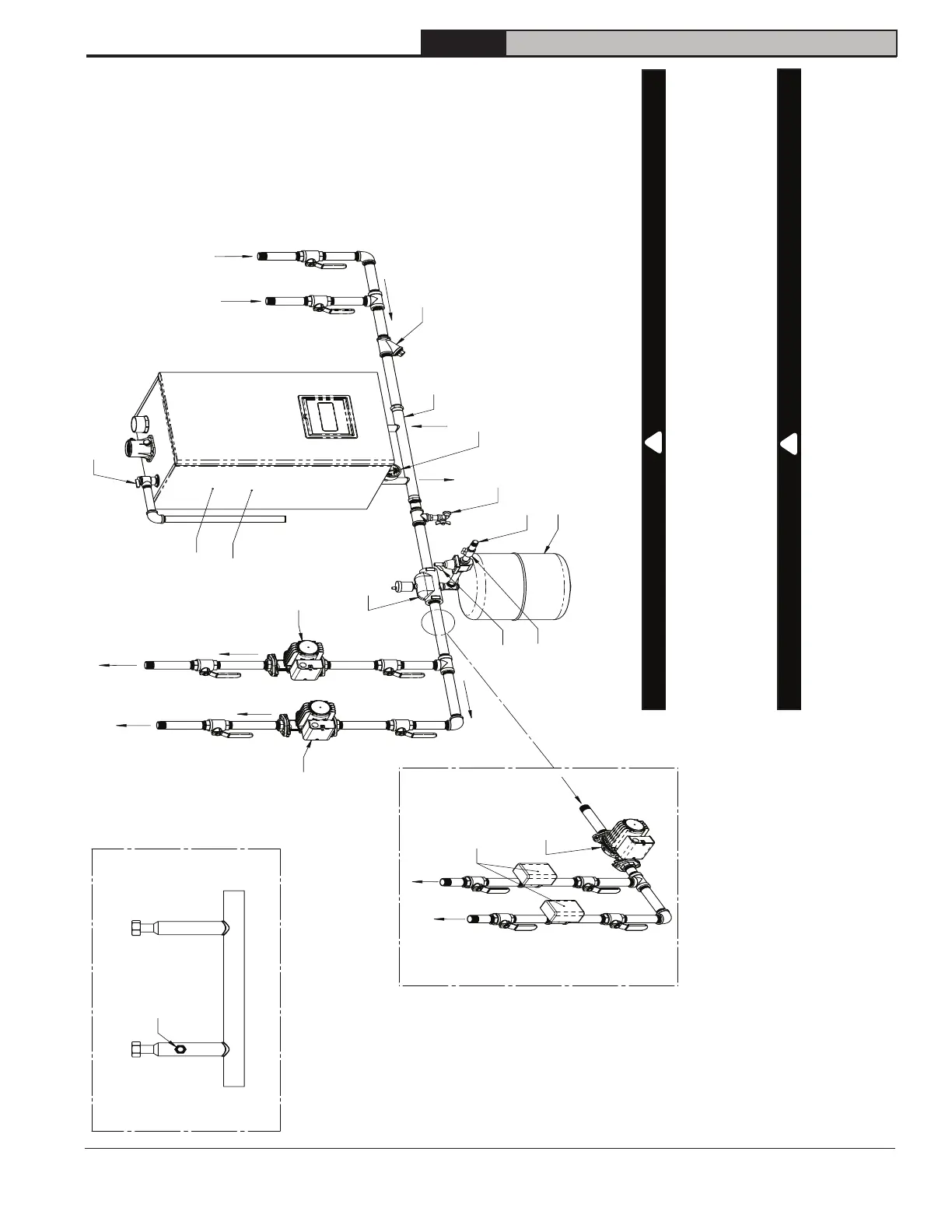

10 Heating System Piping (continued)

From System

To System

Temperature &

Pressure Gauge*

Drain Valve*

Cold Water Fill

Air Separator

& Air Vent

Expansion Tank

Low Loss Header*

Fill Valve

Backflow

Preventer

Safety Relief Valve*

Wye strainer or dirt and

magnetic filter

(highly recommended)

System Pump

w/ Integral Flow

Check Valve

System Pump

w/ Integral Flow

Check Valve

Manual Air Vent*

(inside boiler)

Boiler Pump*

(inside boiler)

* Supplied with boiler

Low Loss Header

Boiler Supply Connection

(G 3/4")

Boiler Return Connection

(G 3/4")

T&P Gauge

(1/4" NPT)

System

Return

(1-1/4" sweat)

Heating

System

Pump

To System

Optional Zone Valve

Controlled System

System Zone

Valves

System

Supply

(1-1/4" sweat)

NOTICE: Domestic water piping omitted for clarity.

NOTICE: Installer is responsible for piping configurations to provide proper flow rates and

meet local codes.

CAUTION

Burn Hazard. Property Damage.

Under some conditions this boiler can deliver water to heating system that is

significantly higher than boiler setpoint. Where such overheat could cause personal

injury or property damage (i.e. low temperature radiant floor zones), protect system

from excessive temperatures using tempering valves or other means.

CAUTION

Component Damage.

Excessive heat from soldering could damage gaskets at connection between low loss

header and boiler. Solder connections to low loss header before installing gaskets.

!

!

Figure 10-2: Heating System Piping

Loading...

Loading...