77110331-01 - 5/20

PHTM II

Installation, Operating & Service Instructions

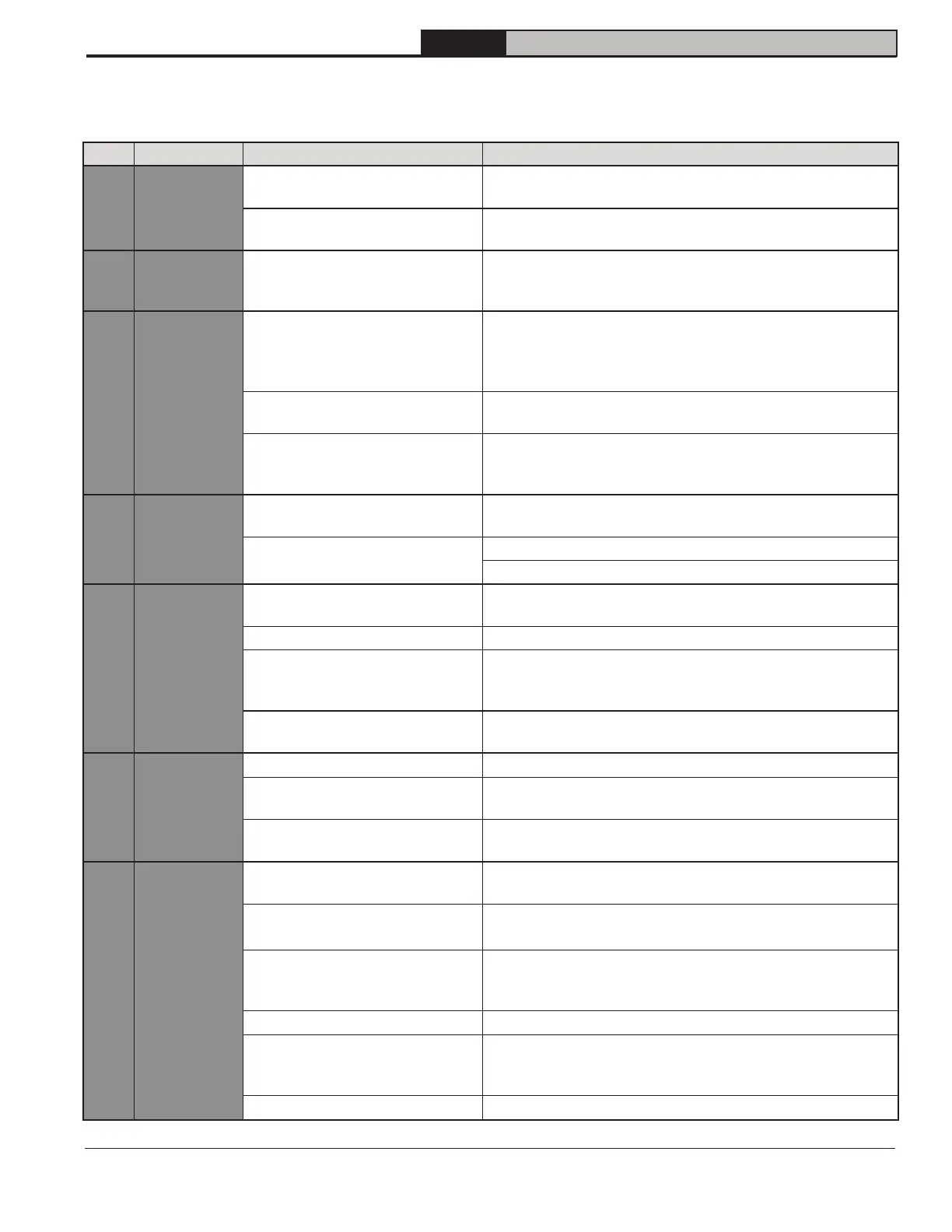

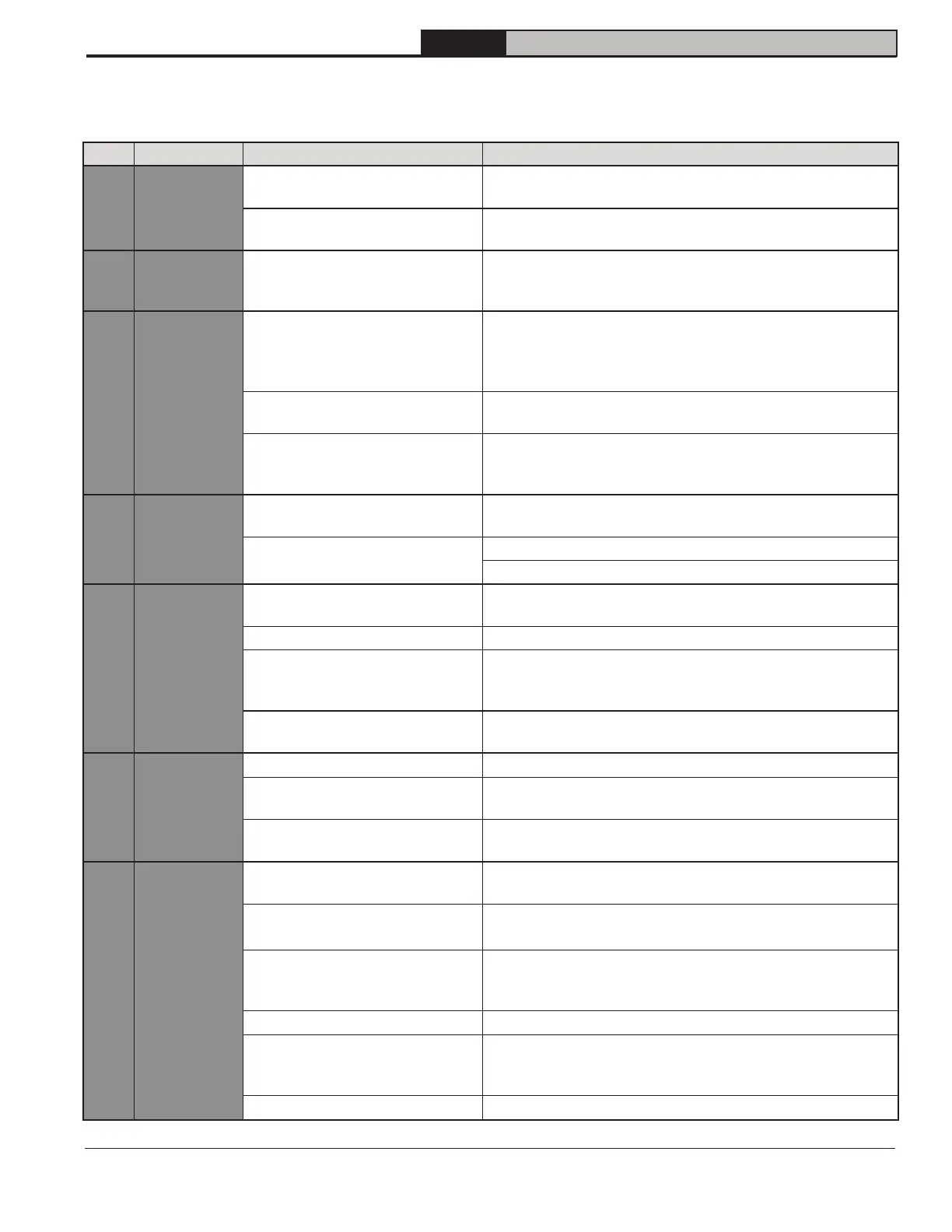

19 Troubleshooting (continued)

Table 19-5: Active Fault Code and Corrective Actions (continued)

Code Name Possible Causes Corrective Action

E18

Invalid

Application

Parameters

[18.7] Factory defaults not

turned on.

Ensure BCC is installed and select A10 factory Default

"On" see Table 16-11.

[18.8] Pump mismatch

Boiler pump set to 0 or boiler pump output set to 3 and

Aux. pump ouput is not set to 3.

E19

Gas Valve Or

Blower Fault

Air fuel ratio is persistently

outside acceptable limit.

Check wiring to gas valve and blower. If wiring is OK,

replace blower and retry. If wiring OK, replace gas valve

and retry.

H20

E20

Ignitor/flame

sensor Or

Burner Fault

Dirty/damaged ignitor/flame

sensor

• Refer to Section 18 Service and Maintenance for proper

procedure to check ignitor/flame sensor.

• Check ignitor/flame sensor distance to burner.

• Replace if necessary.

Ignitor/flame sensor wiring

issue.

Check the ignitor/flame sensor wiring and earth contacts

at burner.

Dirty/ damaged burner.

• Refer to Section 18 Service and Maintenance for proper

procedure to check burner.

• Replace burner if necessary.

H21

E21

Gas Valve

Fault

[E21.3] Gas valve wiring

problem.

Check wiring to gas valve.

Defective Gas Valve.

If problem persists, replace gas valve.

If problem persists, replace control.

H22

E22

No Flame At

Ignition

No gas, insufficient gas supply

pressure.

Verify no air in gas line. Check gas supply pressure.

Check gas pressure down stream of valve.

Ignition Cable not plugged in. Connect ignition harness, check cable has continuity.

Fuel Gas Selection, parameter

A06 or gas valve position is

incorrect.

Check Fuel Gas Selection, parameter A06 and fuel gas

valve setting. Both selections must be set to the same fuel

type. Refer to Figure 15-3.

Lean ignition mixture

After verifying no air in gas piping, gradually increase (1%

at a time) F07 until successful ignition.

H23

E23

Flame Out

Of Sequence

Blocked Condensate Trap. Check trap and clean if necessary.

Ignitor/flame sensor or burner

fault.

Check ignitor/flame sensor or burner (i.e. burner can

touch ignitor/flame sensor if welding is damaged.

Ignitor/flame sensor wiring

faulty.

Check ignitor/flame sensor wiring.

H24

E24

No Flame

After Ignition

Gas supply pressure dropped

after gas valve opened.

Check regular gas flow to boiler and verify no air in gas

line.

Wind => raised min. capacity

valley.

Let the system work with raised min. capacity.

Ignitor/flame sensor or burner

fault.

Check ignitor/flame sensor or burner (e.g. burner can

touch ignitor/flame sensor if welding is damaged),

replace if necessary.

Blocked condensate trap. Check the condensate trap and clean if necessary.

Fuel Gas Selection, parameter

A06 or gas valve position is

incorrect.

Check Fuel Gas Selection, parameter A06 and fuel gas

valve setting. Both selections must be set to same fuel

type. Refer to Figure 15-3.

Control damaged. Replace control if necessary.

Loading...

Loading...