78

PHTM II

Installation, Operating & Service Instructions

110331-01 - 5/20

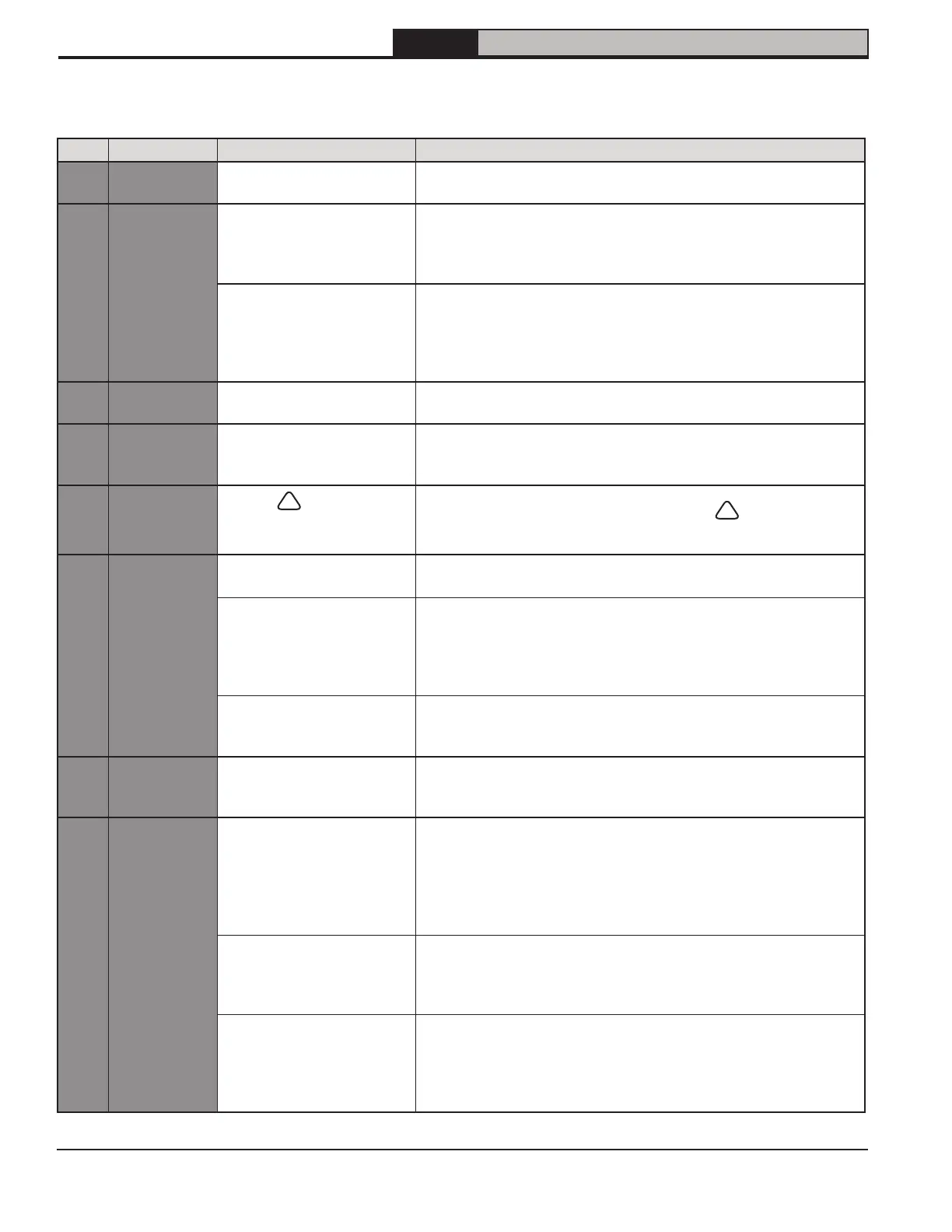

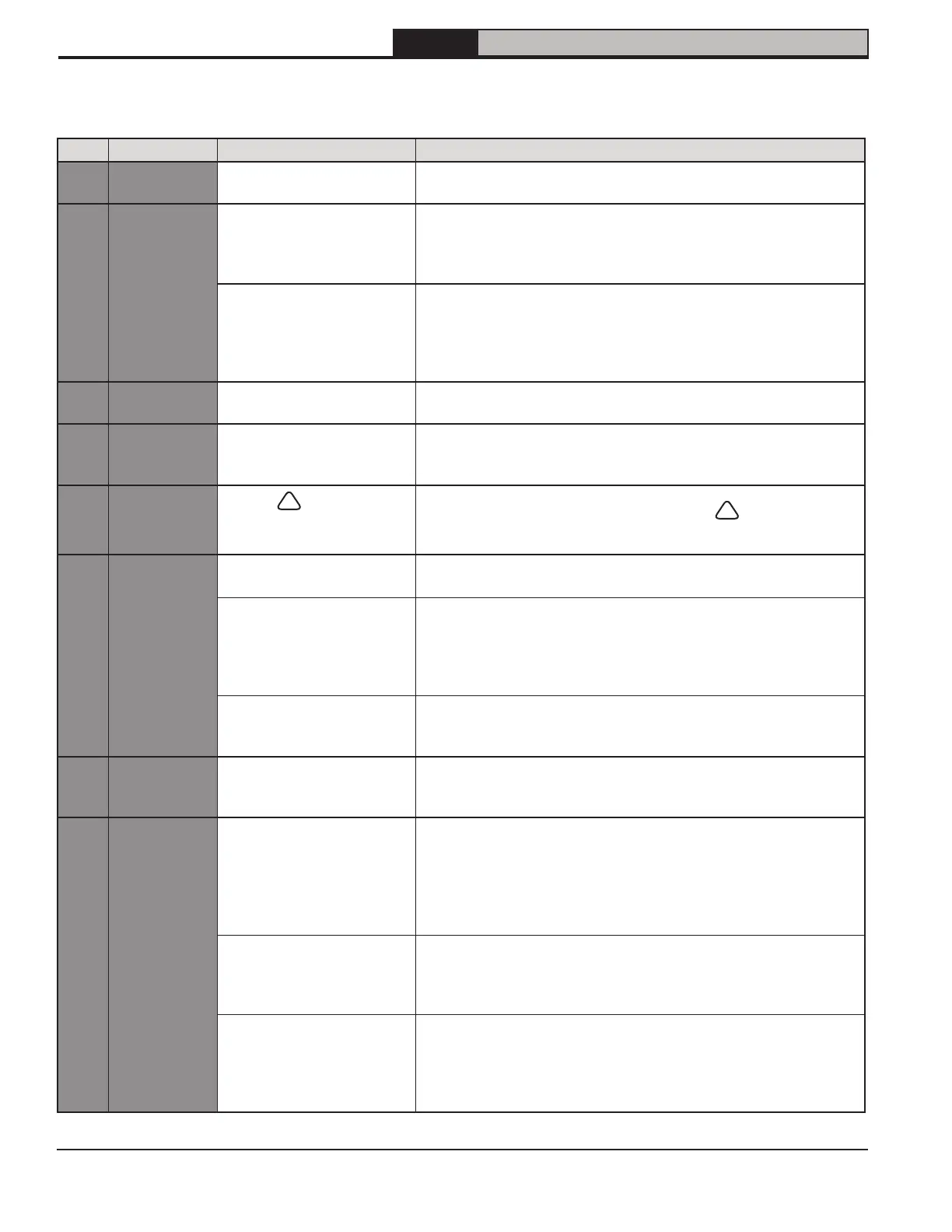

19 Troubleshooting (continued)

Table 19-5: Active Fault Code and Corrective Actions (continued)

Code Name Possible Causes Corrective Action

H25

E25

Hardware

Fault

Control damaged. Check control, try cycle power, replace if necessary.

H26

Calibration

Fault

Too long running without

running at minimum

capacity. Adaptation has

not been possible.

Cycle power to initiate calibration. After H24 boiler runs at

forced raised minimum modulation.

Too long running without

running at calibration

capacity appprox. 47%.

Calibration has not been

possible.

Refer to Supply High Limit (Code H04/E04) for corrective

actions. Cycle power to initiate a calibration.

H27

120 VAC

Supply Fault

120 VAC supply voltage

less than 73 VAC.

Check 120 VAC supply, correct issues as required.

H28

24 VAC

Supply Fault

Control 24 VAC wrong

frequency or high

electrical noise.

Check control, replace if necessary.

E29

Excessive

Reset

Selection

Control

!

reset button

has been selected too

often.

To clear, cycle power to control and press

!

reset button

above local display.

H30

Sequencer

Fault

[30.0] Duplicate Slave

Boiler Addresses.

Ensure each peer-to-peer boiler has a unique salve address

between 1 and 8.

[30.1] Sequencer slave

has lost communication

with Sequencer Master,

master header sensor

failure.

Check boiler to boiler connection wiring.

Check master is powered and configured.

Check header sensor wiring or configuration.

[30.2] Multiple sequencer

masters detected.

Check each boiler Lead Lag Master Enable, parameter L01,

setup. Only one boiler may be set as Sequencer Master

Enabled.

H31

Variable

Speed Pump

Fault

Variable Speed Pump

feedback fault

Check wiring to Variable Speed Pump. Defective pump

electronics or control, replace pump or control if necessary.

H32

Zone Panel

Fault

[32.0 to 32.3] Zone Panel

Communication Lost

Check wiring between panels and boiler. Check Zone Panel

Dip Switch Settings:

- Set Master/Slave Dip Switch to "Slave".

- Set ZC Dip Switch Zone Panel 1 "ZC1" to "ON".

Zone Panel 2 "ZC2" to "ON", etc.

Cycle Power.

[32.4] Zone Panel

Electronics Failure

Check following:

- Wiring Zone Panel main and daughter board.

- Power up one panel at a time to isolate problem.

- Replace panel if problem persists.

[32.5] Duplicate Zone

Panel

Check the following:

- Each ZC Dip Switch set to a unique setting: ZC1, ZC2, ZC3,

ZC4

- When multiple switches are set to "ON" the zone is reported

as panel 1.

Loading...

Loading...