18

Troubleshooting Instructions

The slushy machine you receive is a mechatronic professional equipment that integrates computer

program control, mechanical transmission and ecient refrigeration system! You must arrange for

your own personnel to be responsible for the operation and maintenance of this equipment, at the

same time, please understand the installation and maintenance requirements of this equipment in

detail when purchasing the machine, and receive professional training before use!!! (Ve impoant)

For the violation of the installation, use and maintenance requirements of the machine caused by

equipment failure, is not within the scope of the company's warranty!

At the same time, for the problems encountered in the process of use, please strictly follow the

following precautions:

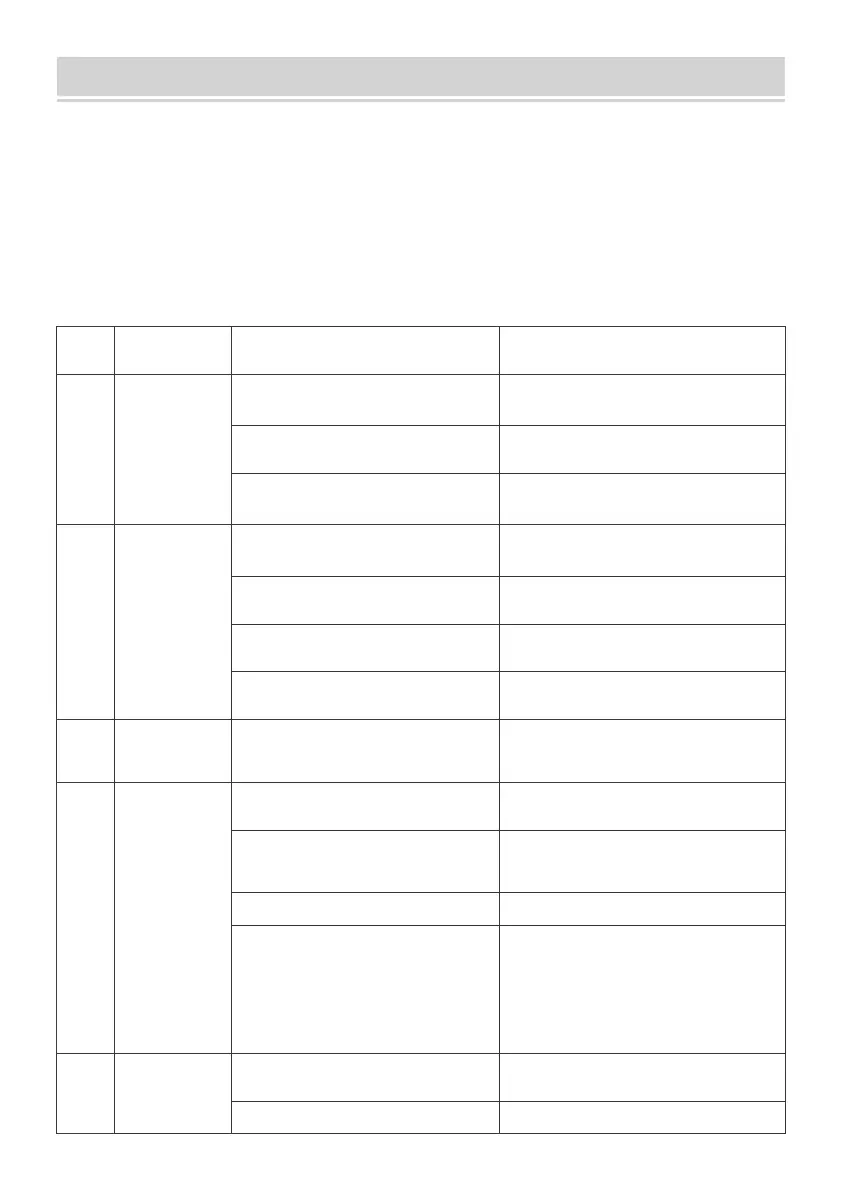

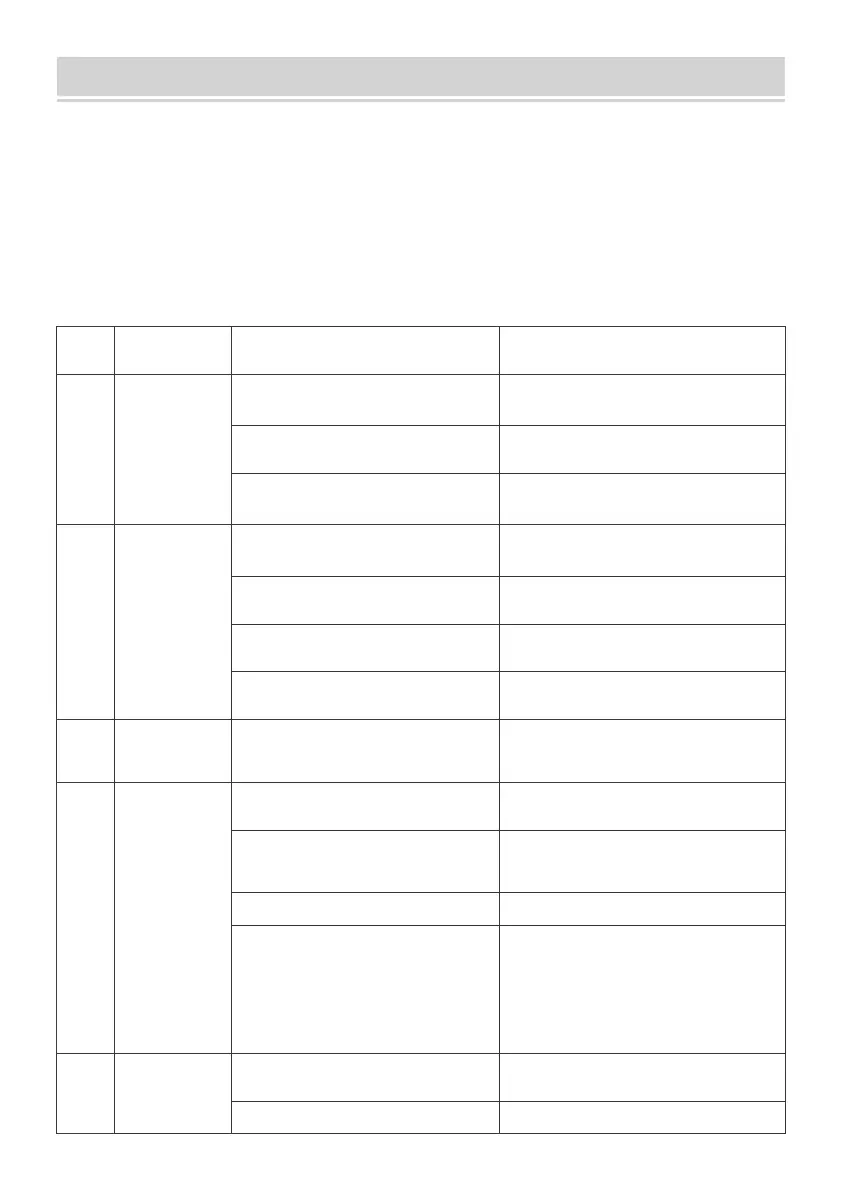

Serial

number

Cause Analysis Processing method

Is the power switch of the equipment

energized

Check the power supply, plugs and

sockets

The internal wires of the machine are

chewed or loosened by rats

Hire a professional electrician to replace

or x

The computer board of the equipment

fails

Call the company's phone number to be

handled by the company's professional sta

Insucient input power line or

switch load

Hire your own professional electrician for

replacement

The internal circuit of the equipment is

chewed or broken by rats

Hire a professional electrician to replace or

wrap

Excessive load on equipment due to high

gear setting

Downward gear adjustment

Sho circuit inside the motor, circuit

board or compressor

Call the company's phone number to be

handled by the company's professional sta

The machine case has inductive

electricity

Check whether the power inlet line is

reliably grounded, no grounding wire; if it is

worn, you need to replace it with a new one

D-seal is not installed properly

Check whether the two D-rings of the

outlet valve are installed in the slot

Broken O-ring of beating rod

Take down the beating rod to check

whether the seal at both ends is worn,

there is wear need to replace the new

Fastening screws are not tightened Tighten the four screws evenly diagonally

Incorrect disassembly or installation

method of beating rod, resulting in

broken beating rod seal and leakage of

material or water

Gently pull out veically when

disassembling, and always apply medical

petroleum jelly as lubricant when installing,

apply it around the valve stem seal and

press down veically. Do not damage the

seal with sharp objects when cleaning.

The discharge head screw is not

tightened

Tighten the four screws evenly diagonally

Worn seal at the back end of the agitator Replace rear end seal

The residual

material pipe

leaked material

and water

Leakage of water

and material on

or under the

discharge head

after staing the

machine

Power switch

tripped after

power on

No display after

power on

Feeling of

leakage after

power on

1

2

4

3

5

Loading...

Loading...