5.6 Establishing the electric con-

nection

NOTICE

Damaging of the machine

through heavy voltage

fluctuations and power surges

Heavy voltage fluctuations and power surges can

disrupt the control unit and can cause system failures.

Connect the machine to a dedicated current circuit

or ensure that no devices are connected that can

cause heavy voltage fluctuation when switched on.

If heavy voltage fluctuations cannot be avoided,

install a surge protector that protects the machine

from heavy voltage fluctuations.

NOTICE

Short-circuit hazard when the

machine is too cold

If the machine is transported from a cold environment

into a warmer environment, a short circuit may occur

caused by condensate.

Before switching on the machine after trans-

portation, ensure the following:

n

The ambient air has the allowed temperature.

n

The machine has the same temperature as the

ambient air. This will take at least 48 hours.

n

The machine is completely dry.

The machine requires a continuous power supply for

proper operation.

1. Plug the provided power cable into the power con-

nection at the connection panel of the machine.

2. If power failures occur regularly at the installation

location or if there are frequent voltage fluc-

tuations, install an Uninterruptible Power Supply

(UPS), type online/ VFI (IEC 62040-3, class 1).

If a power failure occurs during job execu-

tion, the tool may break and the blank may

be destroyed.

3. Insert the plug of the cable into a socket that is pro-

tected by a Residual Current Device/ Ground Fault

Circuit Interrupter.

5.7 Integrating the machine into the

network

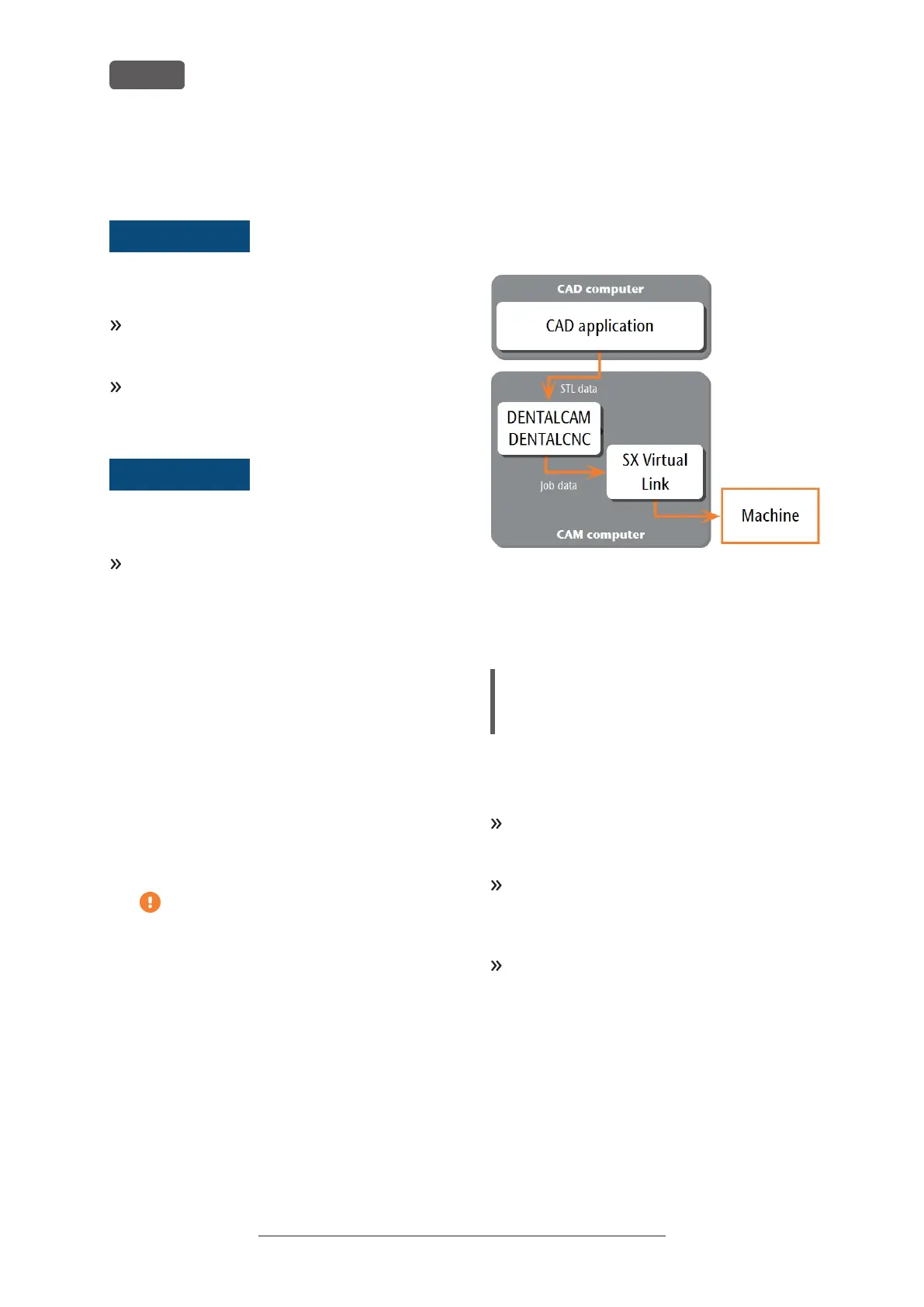

The following diagram visualizes how commands are

sent to the machine using our network technology:

FIG. 19 DIAGRAM: HOW COMMANDS ARE SENT OVER THE NETWORK

SX Virtual Link is similar to a device driver that transfers

data between DENTALCNC and the machine.

The network integration workflow is as follows:

1. Prepare the installation.

2. Configure SX Virtual Link and DENTALCNC.

Preparing the installation

For integrating the machine into your network, you

will require the assistance of your IT specialist.

Ensure that your network is working without disrup-

tions. Network failures will lead to aborted jobs and

unusable machining results.

Do not contact customer support for setting up your

network or troubleshooting network issues.

Customer service will only help you with machine-

related issues.

If you want to control multiple machines with 1 CAM

computer, use our multi-machine control feature.

See the documentation for the manufacturing soft-

ware.

1. Plug the Ethernet cable into the network port at the

connection panel of the machine.

2. Plug the other end of the Ethernet cable into the

network port of the CAM computer. Do not use a

router, hub or switch to connect the 2 units at this

point.

Original Operating Instructions:R5

Version: 12/16/2021

R5 – Installing the machine

EN 24

Loading...

Loading...