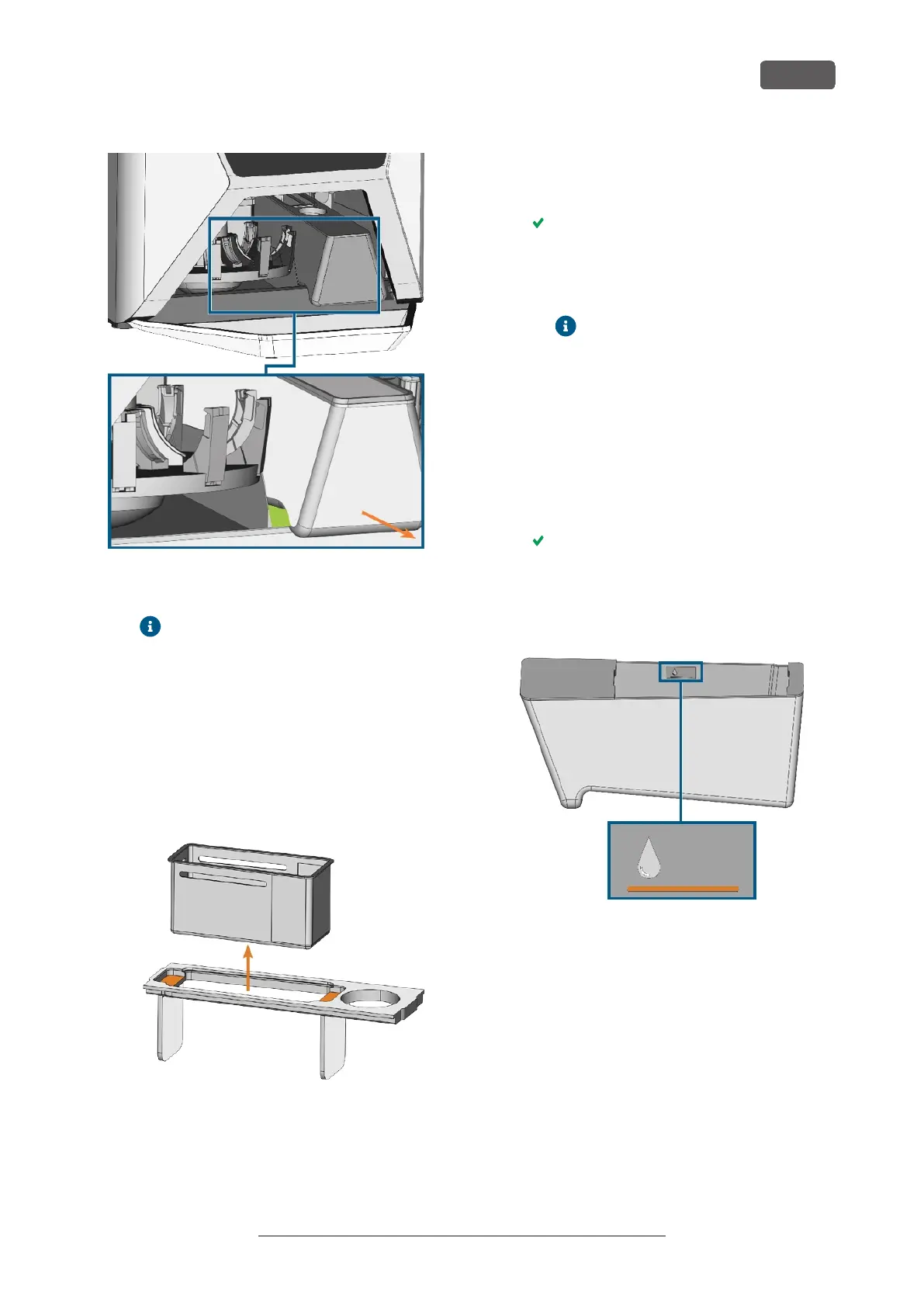

FIG. 37 REMOVING THE COOLING LIQUID TANK FROM THE MULTI-

PURPOSE COMPARTMENT; GRAB TANK AT THE GREEN AREA

Information on the disposal of cooling

liquid and machining residues: Disposal –

on page74

6. Lift the cover off the tank.

7. If there is cooling liquid in the tank:

a. Pour the cooling liquid into the collecting

container.

b. Use the recessed surfaces at the sides of the

strainer basket to pull it upwards.

FIG. 38 REMOVING THE STRAINER BASKET (RECESSED

SURFACES COLORED ORANGE)

c. Tap out the strainer basket into the collecting

container. You can use water or compressed

air to further clean the strainer basket.

The strainer basket is completely void of

machining residues.

d. Rinse the filter in the cooling liquid tank

under running water.

If necessary, you can disassemble the

cooling liquid filter to clean it thor-

oughly. Operation: Preparing jobs –

on page31

e. Thoroughly clean the tank with the cleaning

brush. Pour the cleaning water into the col-

lecting container.

f. If you have used a cleaning agent, ensure that

no residues of it remain in the cooling liquid

tank.

The cooling liquid tank is completely void of

liquid, machining and cleaning agent

residues.

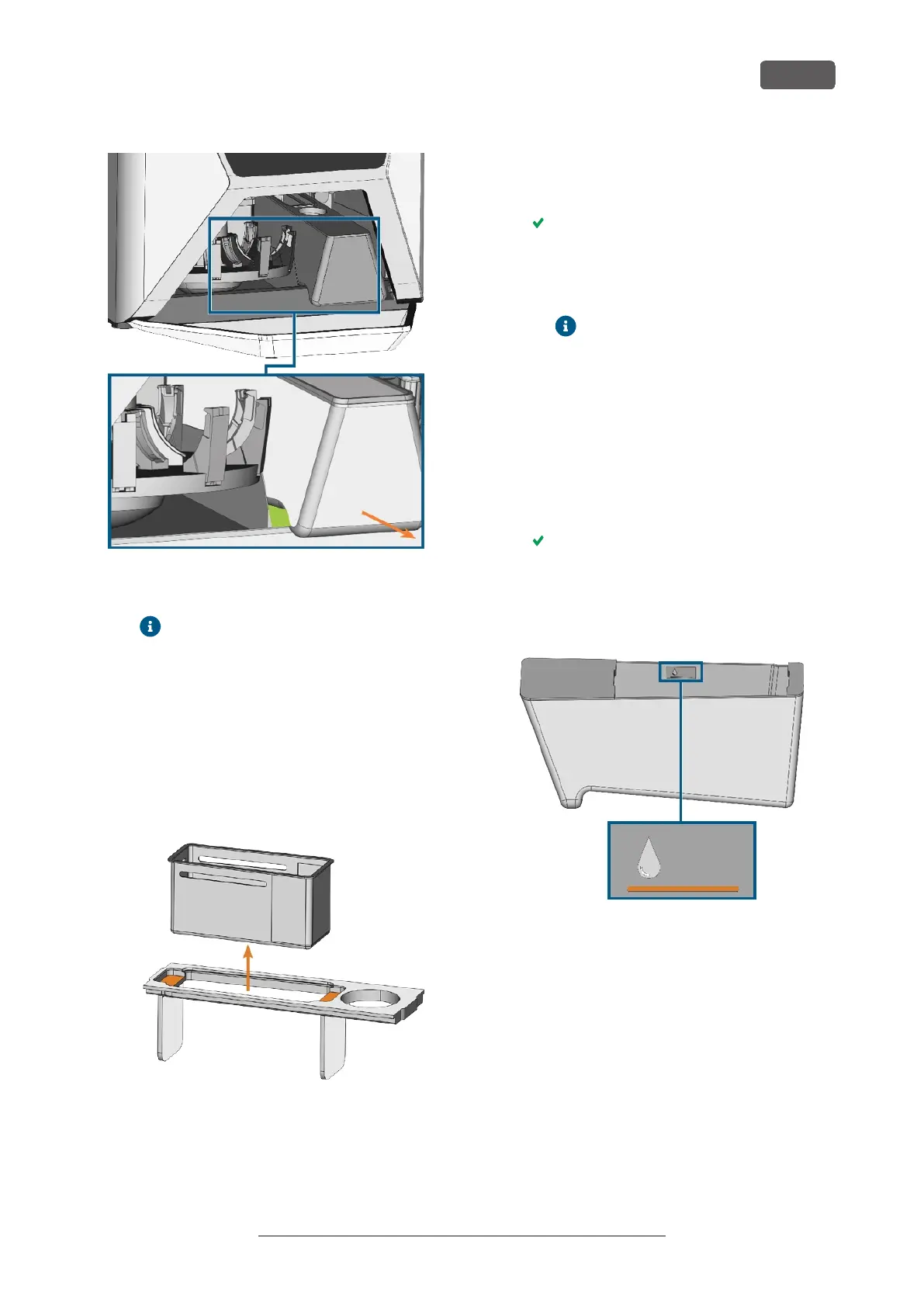

8. Fill the cooling liquid tank with cooling liquid until

it reaches the max mark.

FIG. 39 THE MAX MARK (COLORED ORANGE) ON THE LABEL INSIDE

THE TANK

9. When processing titanium blanks: Add the cooling

lubricant Tec Liquid Pro to the cooling liquid. The

mixing ratio is indicated on the bottle label.

Determine the pH value of the cooling liquid.

Determining the pH value of the cooling liquid with

test strips – on the previous page

10. Insert the strainer basket into the tank cover and

put the cover onto the tank.

11. Remove dirt and foreign bodies from the coupling

of the cooling liquid tank and the counterpart in

the machine.

R5 – Operation: Preparing jobs

EN 35

Original Operating Instructions:R5

Version: 12/16/2021

Loading...

Loading...